English (GB)

13

6.2 Twin-head pumps with relay module

The pump is connected directly to the mains as it

incorporates overload protection at all three speeds.

The pumps are factory-set to alternating operation

as duty and standby pump. Pump change takes

place every 24 hours.

Figures 14 to 16 at the end of these instructions

show the possible connections and the setting of the

selector switch for the various operating modes.

• Fig. 14: Alternating operation.

• Fig. 15: Standby operation with pump 1 as duty

pump and pump 2 as standby pump.

• Fig. 16: Standby operation with pump 2 as duty

pump and pump 1 as standby pump.

In the case of single-pump operation, the cable

between the pumps is to be removed. The pumps

must be set individually and connected separately to

the mains. See figs 17 and 18:

• Fig. 17: Electrical connection and setting of the

selector switch when using the signal output for

operating indication.

• Fig. 18: Electrical connection and setting of the

selector contact when using the signal output for

fault indication.

Fault or operating indication for twin-head

pumps in alternating operation

If the signal output is to be used for fault or operating

indication, an intermediate relay must be used.

Figure 19 shows a single-phase pump in alternating

operation with external fault indication if pump 2 or

both pumps are faulty.

Fault or operating indication for twin-head

pumps in standby operation

If the signal output of the duty pump is to be used

for fault or operating indication, an intermediate relay

must be used.

If the signal output of the standby pump is to be

used for fault or operating indication, proceed as

shown in fig. 17 or 18.

6.3 Frequency converter operation

We do not recommend the UPS and UPSD pumps

for frequency converter operation for the following

reasons:

• The noise level will increase.

• The life of the motor insulation system will be

reduced due to voltage peaks caused by the

frequency converter.

• On three-phase pumps, the indication of the

indicator light will be wrong. It will always be red.

• Pumps fitted with protection or relay module must

not be connected to a frequency converter.

We recommend Grundfos MAGNA and

UPE Series 2000 which have built-in frequency

converter.

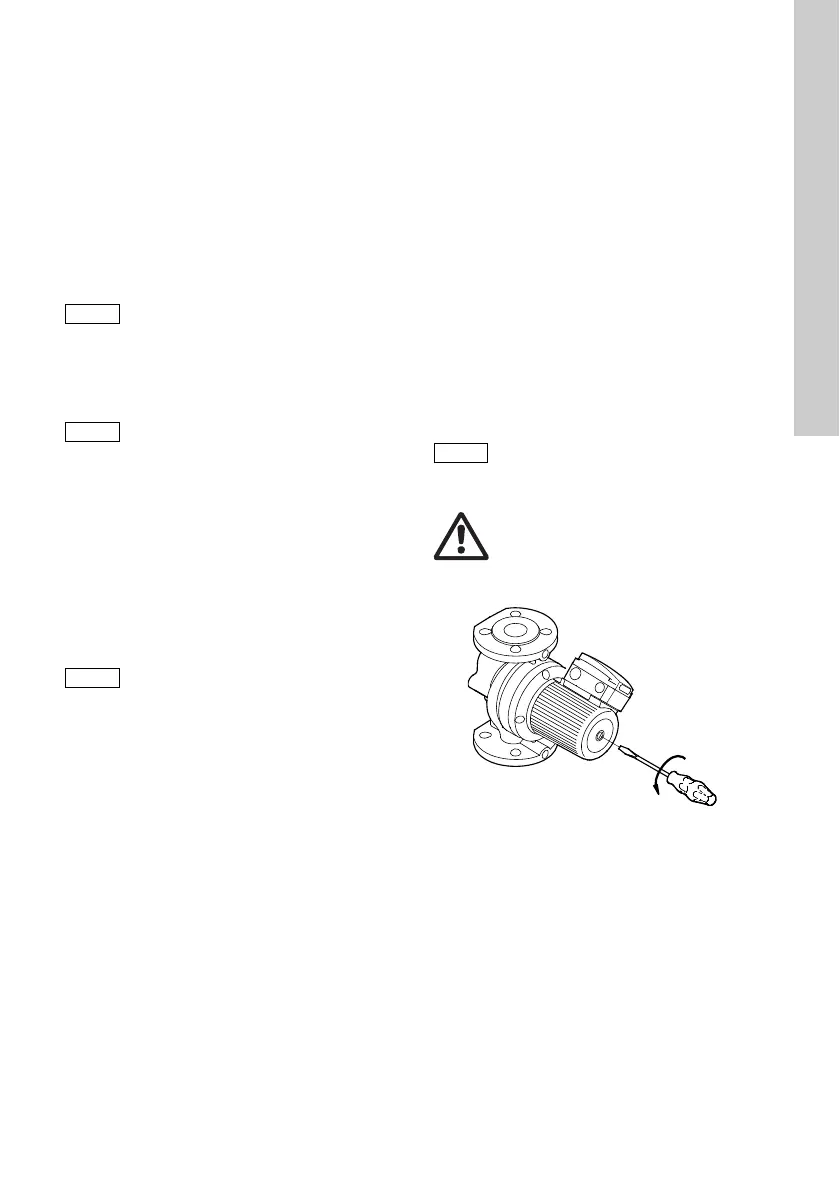

7. Start-up

Do not start the pump until the system has been filled

with liquid and vented. Furthermore, the required

minimum inlet pressure must be available at the

pump inlet. See page 330.

Fig. 9 Venting the pump

The selector switch of pump 2 must

have been set to either fault or

operating indication in this operating

mode.

The selector switch of pump 1 must

have been set to either fault or

operating indication in this operating

mode.

In the case of single-pump operation,

the selector switch must be set to

either fault or operating indication.

The system cannot be vented through

the pump.

Warning

If the inspection screw (fig. 9) is to be

slackened, care should be taken to

ensure that the escaping, scalding hot

liquid does not cause personal injury

or damage to components.

TM02 1405 1101

Loading...

Loading...