23

HARDI NAVIGATOR

CLEANING PROCEDURE

WARNING!

It is essential that the water in the Flush Tank

which is used to clean your sprayer is clean

and free of contamination.

Good maintenance and spray operation tech-

nique will prevent accidental recontamination

of the system during the cleaning process.

Back-flow due to poor seals in hose connections,

leaking valves and O-rings, incorrect plumbing

setup or fittings, poor filling technique or

spillages of chemicals may all cause contamin-

ation.

If Flush Tank contamination has occurred, fill

with water containing the appropriate chemical

decontamination agent.

Emptying and refilling Flush Tank several times

with clean rinse water will be needed before

proceeding with general cleaning of the system.

1 As described on Page 20, before cleaning, it is

necessary to dilute the remaining spray liquid in the

main tank with at least 10 parts of water and spray

the liquid out into the field you have just sprayed.

2 Select and use the appropriate protective clothing.

Select a detergent suitable for cleaning (and

suitable deactivating agents if necessary for

decontaminating / neutralising residues).

3 Flush and clean the sprayer and tractor externally.

Use detergent if necessary.

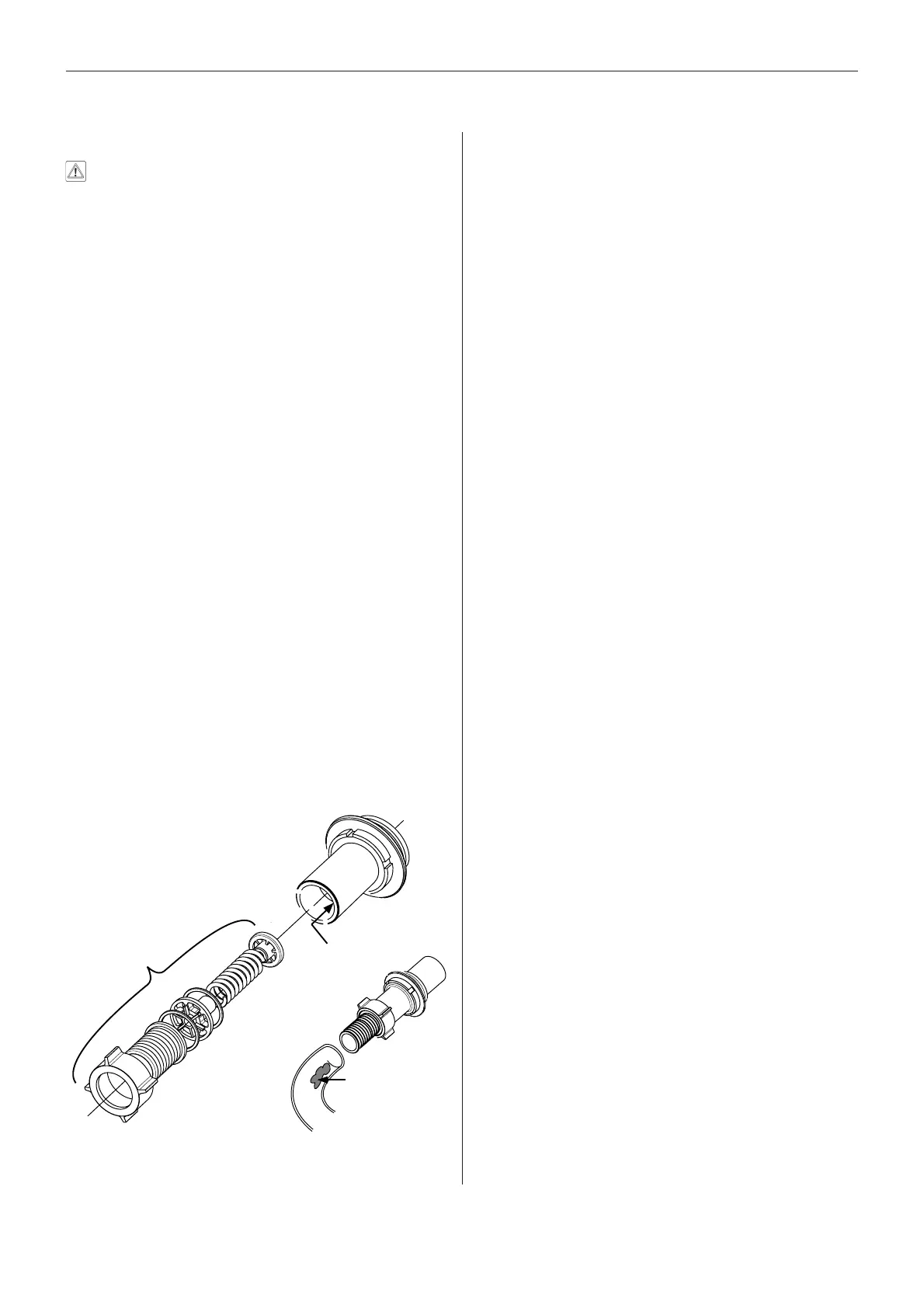

4 Remove nozzles, tank filters, nozzle filters and

suction filters and clean with appropriate solution

(Refer to

Navigator Service Manual

).

Be careful not to damage the mesh. Refit the

suction filter top. Refit the filters when the sprayer

is completely clean.

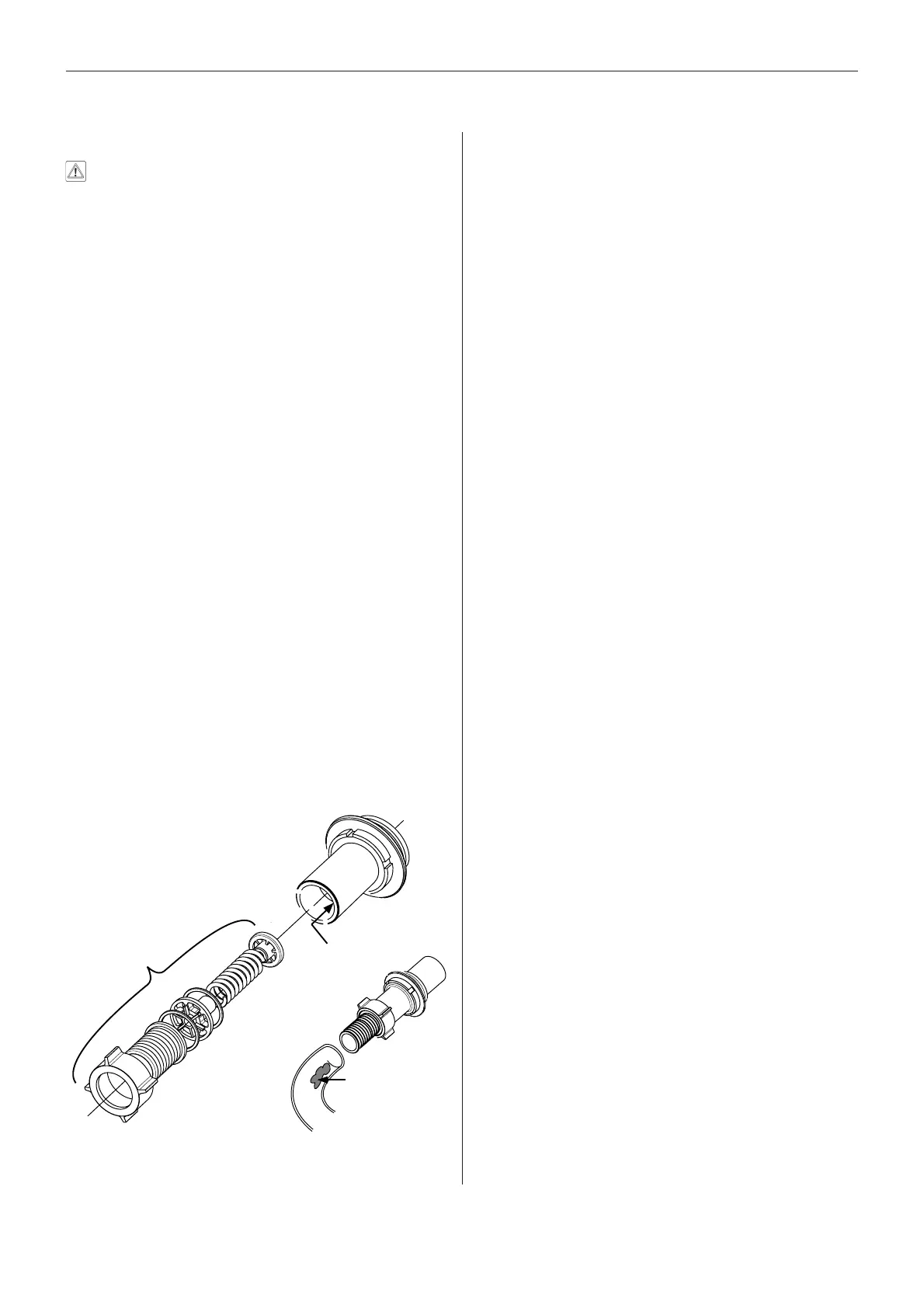

5 Inspect pressure relief valve(Fig 51)(mounted on

the side of the Select Function Valve assembly).

Ensure it is thoroughly cleaned, rinsed and free of

residues. Ensure the bleed hole is clear of debris

and the pressure relief valve is bypassing fluid back

into the main tank during normal spray operations.

6 Inspect delivery hose from the relief valve, clear

away any build-up and ensure the hose and

connections are thoroughly cleaned and rinsed.

7 Remove, clean, drain and flush all hoses.

8 Clean GRANNI POT chemical filler hopper.

Clean, flush and drain delivery hose from filler to

main tank. See Granni Pot Operators Manual.

9 Carefully clean Main Tank lid area, particularly the

basket and underside of lid.

10 With the pump running, thoroughly flush the inside

of the main tank (remember the tank roof and lid

area). If rinse nozzles are not fitted use pressure

cleaner etc to clean internal tank surface with

appropriate cleaning solution.

Flush and operate all components and any equip-

ment that has been in contact with chemicals.

Before opening the distribution valves and spray-

ing the liquid out please identify a suitable method

of disposing of any contaminated tank rinsing solution.

11 Empty the tank as much as possible and minimise

the amount of chemical particles remaining in

the system. For the last stages of emptying, turn the

SELECT FUNCTION handle towards SPRAY NO

AGITATION.

VERY IMPORTANT! Although your

sprayer system has been flushed with

clean water at this stage, it is essential

to follow up by thoroughly decontami-

nating the entire sprayer, all accesso-

ries and chemical handling equipment

before spraying with another chemical,

or storage.

Many agricultural chemicals have

properties which mean that molecules

have a strong attraction to some

surfaces, and flushing with water

alone may not dislodge all traces.

Neutralising the chemical residues

that may have adhered to various

surfaces within any sprayer system

will prevent damage to your next

crop, or unexpected results from the

next chemical used.

Fig 51

Inspect hose

and connections,

clean and rinse

thoroughly

Check

bleed hole

is clear

Clear any

build-up in hose

Loading...

Loading...