–

The automatic decompressor has the

following positions; Fig. 93:

0 = Operating position, with engine

running

1 = Permanent decompression, automatic

device switched off

2 = Automatic decompressor switched on,

engine compression is built up auto-

matically after about 8 turns of the

handle.

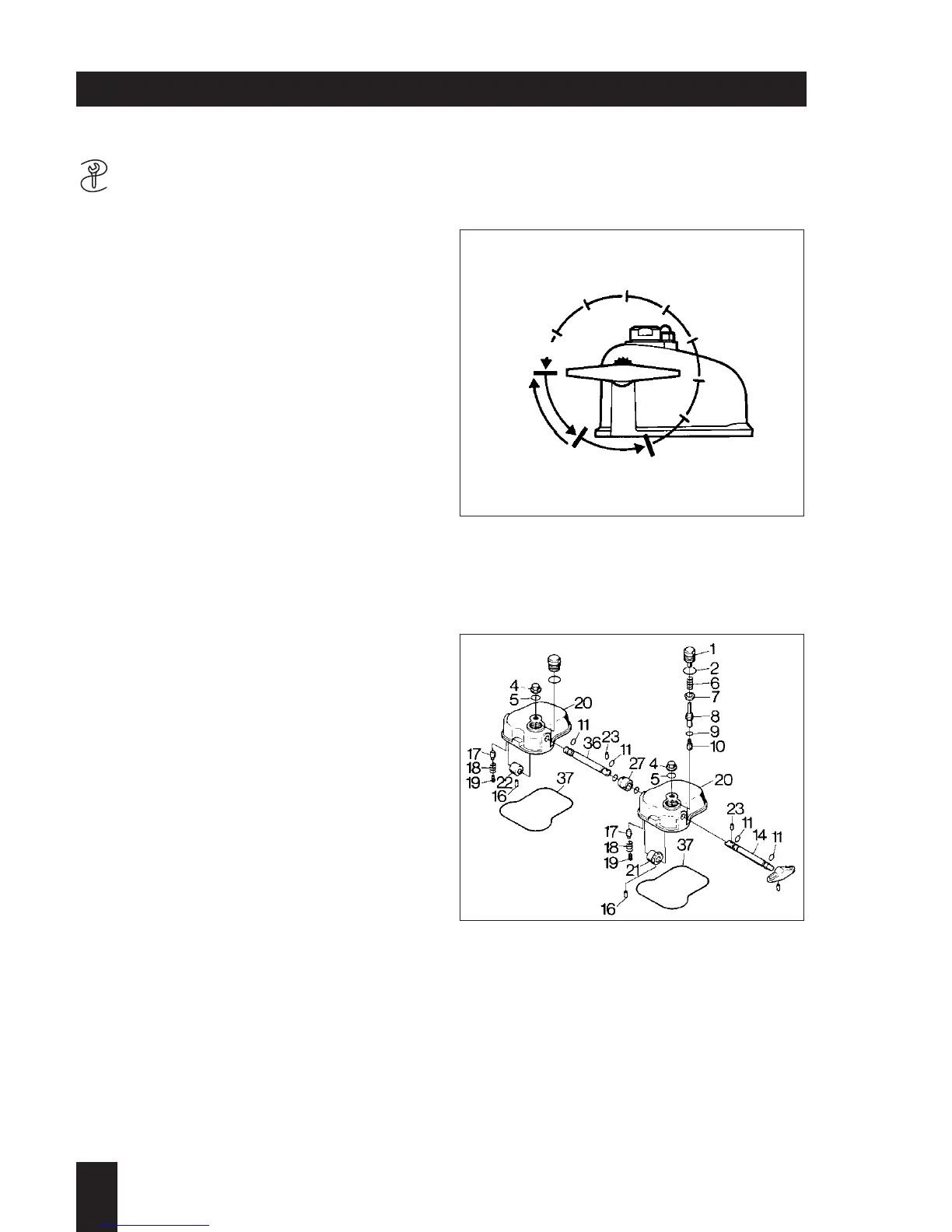

Detaching:

– Unscrew cap nut (94/4) with sealing ring

(94/5).

– Take off cover (94/20) with gasket

(94/37).

On two-cylinder engines, shafts (94/14)

and (94/36) are connected together by

coupling sleeve (94/27) and 2 locking

collets (94/23). Camwheel (94/22) is then

used at the second cylinder (flywheel

side) instead of the gearwheel.

Dismantling the automatic decompres-

sor:

– Unscrew and remove screw plug (94/1).

– Take out sealing ring (94/2), spring

(94/6), cap (94/7) and lifting pin with

shims and pressure pin (94/8, 9, 10).

– Unscrew threaded rod (94/19) and

remove spring (94/18) and pressure pin

(94/17).

– Using a suitable split-pin driver, drive

locking collet (94/16) about 3 mm into

gearwheel (94/21).

– Turn the gearwheel through 180° and

pull the locking collet out with pliers.

– Take out shaft (94/14) and gearwheel.

2

L / M . . 09.96

93

94

A 04.00 Start mechanical

A 04.20 Automatic decompressor (M 31, M 40, M 41)

Loading...

Loading...