English

17

6. Angular cutting

The base can be swiveled to both sides by up to

45° for angular cutting. (Fig. 21)

(1) Loosen the base bolt by allen wrench attached on

base and move the base fully forward. (Fig. 16,

17)

(2) Align the scale (from 0 degrees to 45 degrees by 15-

degree increments) of the semi-circular part of the

base with the [ ] mark on the gear cover. (Fig. 22)

(3) Tighten the M5 bolt again. (Fig. 16)

(4) Set the orbital position to “0”.

NOTE:

Angular cutting can not be done when adopting

chip cover or dust collector.

(6) Insert dust collector into the rear hole of the base

until the hook catches in the notch. (Fig. 24)

(7) Press the hook to remove the dust collector.

NOTE:

Wear the dust mask additionally, if available.

CONCERNING CUTTING OF STAINLESS

STEEL PLATES

CAUTION:

In order to prevent blade dislodging, damage or

excessive wear on the Plunger, please make sure to

have surface of the base plate attached to the work

piece while sawing.

When cutting stainless steel plates, adjust the unit as

described below:

1. Adjust the speed

NOTE:

The higher the speed is, the quicker the material is

cut. But the service life of the blade will be reduced

in this case. When the speed is too low, cutting

will take longer, although the service life will be

prolonged. Make adjustments as desired.

Fig. 21

Base

Fig. 22

-mark

Semi-

circular part

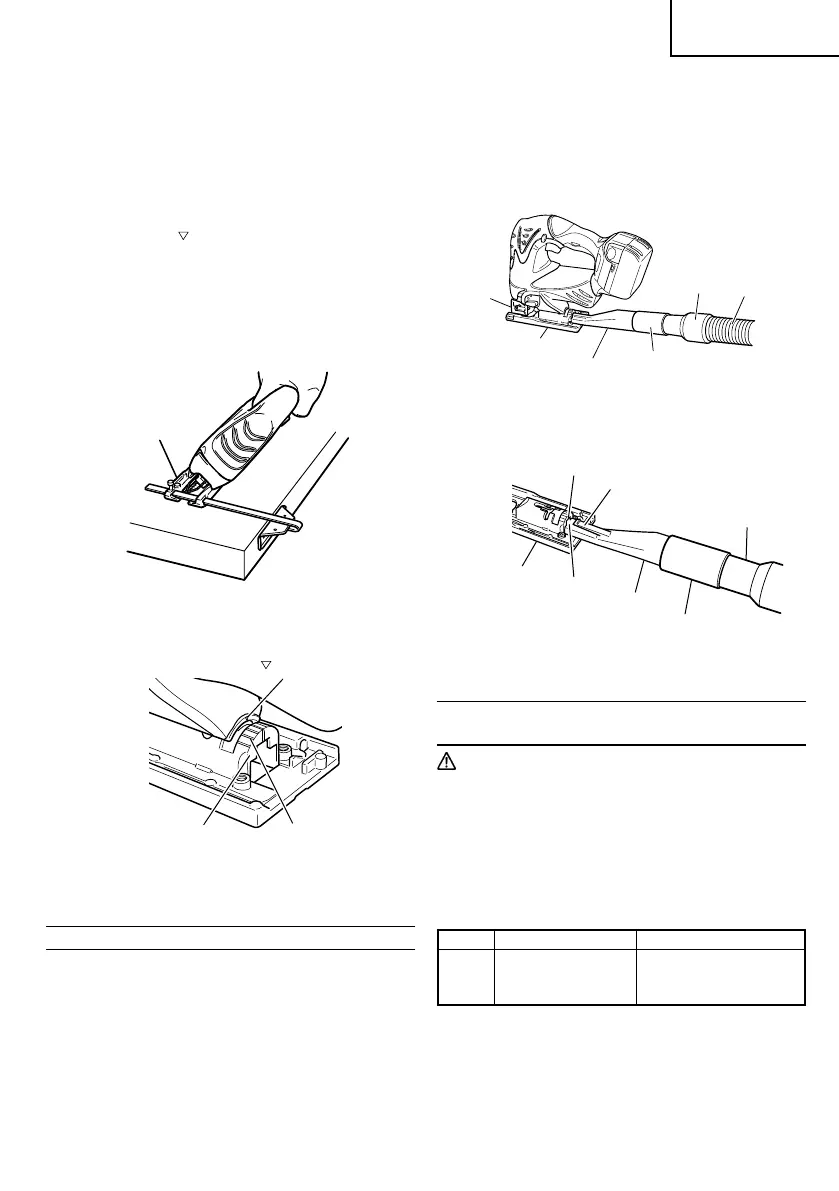

CONNECTING WITH CLEANER

By connecting with cleaner (sold separately) through

dust collector (sold separately) and adapter (sold

separately), most of dust can be collected.

(1) Remove the allen wrench from the base.

(2) Move the base fully forward. (Fig. 16, 17)

(3) Attach the chip cover.

(4) Connect the dust collector with adapter. (Fig. 23)

(5) Connect the adapter with the nose of cleaner. (Fig.

23)

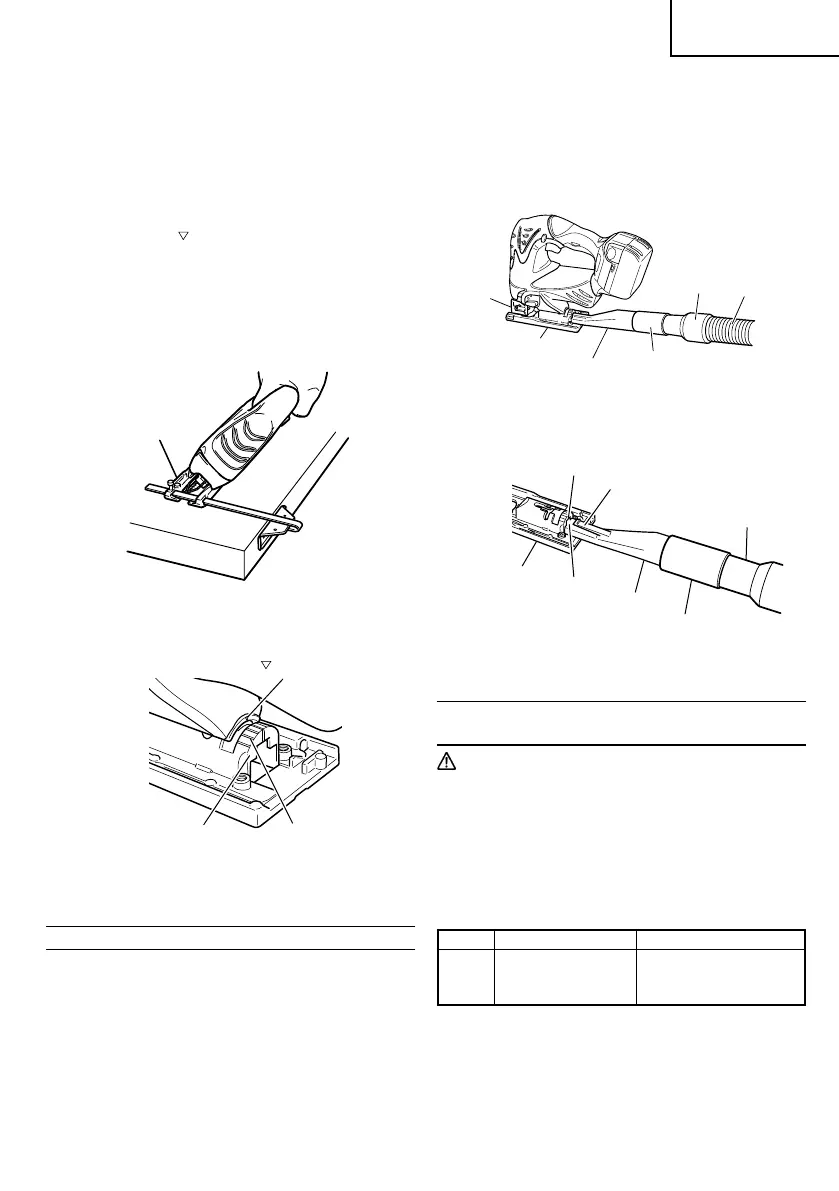

Fig. 24

Base

Rear

hole

Dust

collector

Adapter

Nose

Hook

Notch

Blade Thickness of material Speed

1/16” – 5/32”

No. 97

(1.5 – 2.5 mm)

Middle speed

Fig. 23

Base

Chip

cover

Dust

collector

Adapter

Nose

Cleaner

Scale

01Eng_CJ14DSL_US 08/11/7, 09:3217

Loading...

Loading...