--- 7 ---

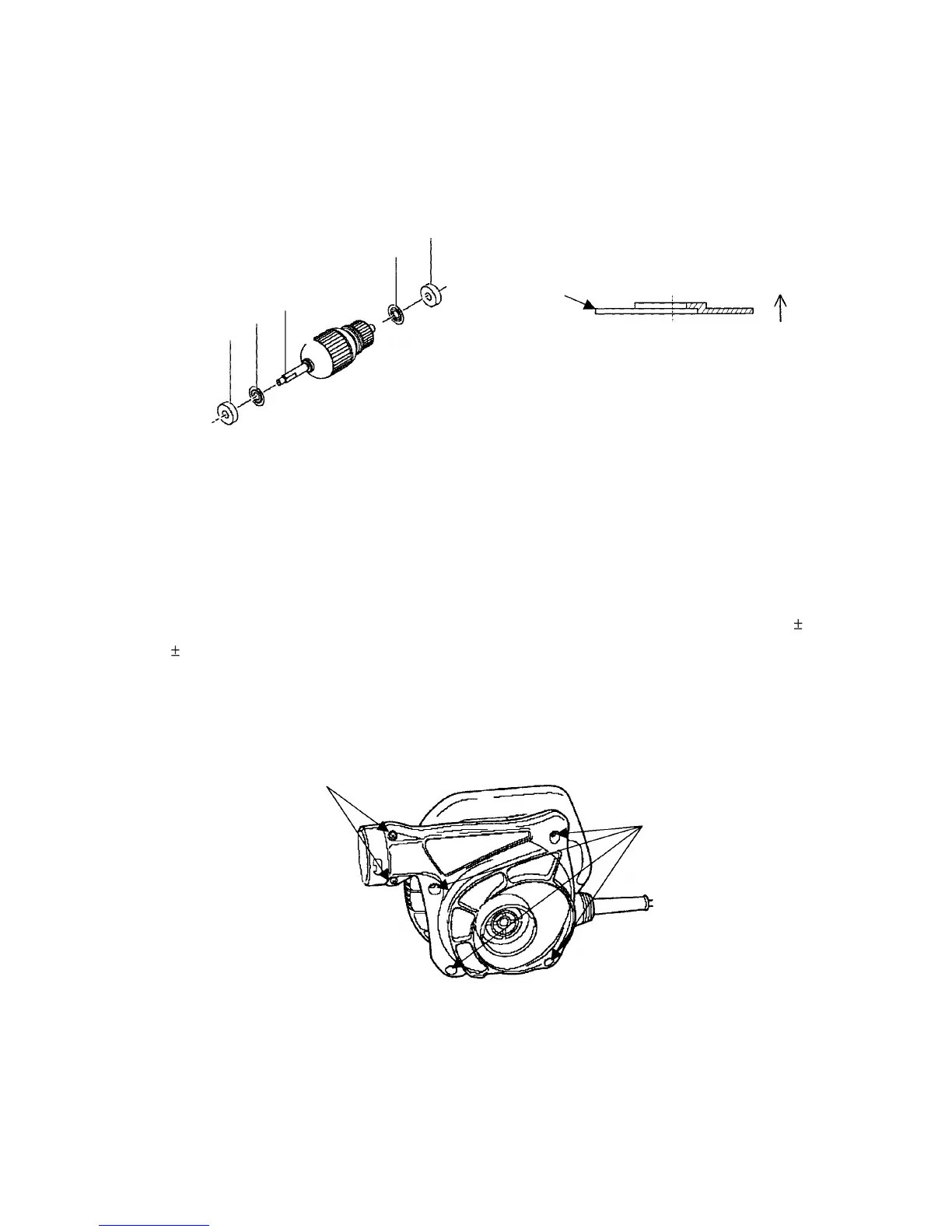

Fig. 6

7-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

[13]

[14]

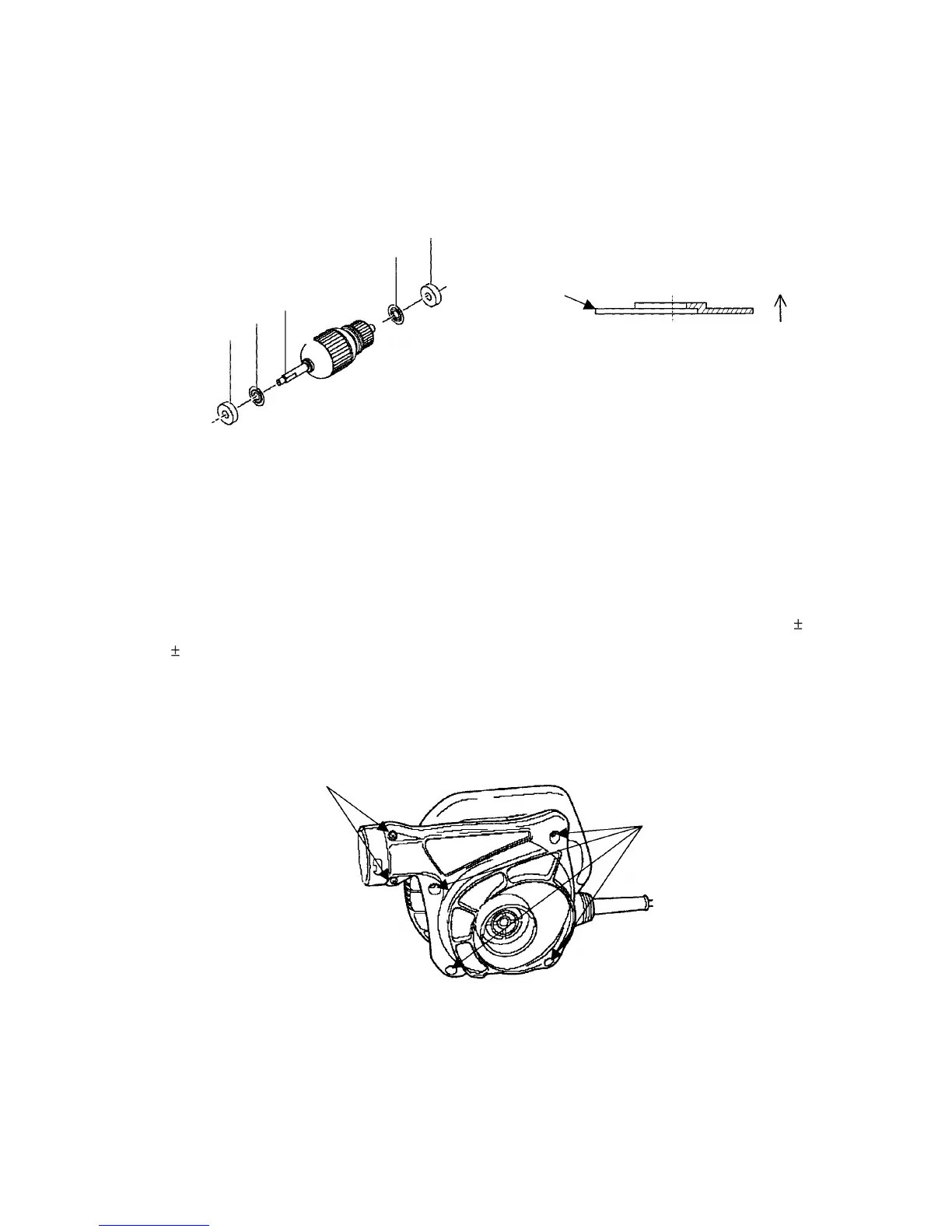

Fig. 8

Fig. 7

[19]

[15]

[14]

(1) Mount Washer (A) [14] to the Armature [15] so that the convex side of Washer (A) [14] faces the ball bearing.

Press-fit the Ball Bearing 608DDW [13] as far as it will go.

(2) Check that the Bearing Lock [12] is mounted to the ball bearing chamber of the Housing Ass'y [20]. Then put

the Armature [15] in the Stator Ass'y [18].

(3) Check that the Bearing Lock [12] is mounted to the Casing [8]. Secure the Casing [8] to the Housing Ass'y

[20] with the Tapping Screws (W/Flange) D5 x 30 [10].

(4) Mount the Washer [11] to the armature shaft. Insert the Fan [7] aligning with the width across flat of the

armature shaft and secure it with the U-Nut M6 [6]. The tightening torque of the U-Nut M6 [6] is 2.9 0.5 N

•

m

(30 5 kgf

•

cm). Be careful not to overtighten the U-Nut M6 [6].

(5) Secure the Casing Cover [5] to the Casing [8] with two Tapping Screws (W/Flange) D4 x 20 (Black) [9] and

four Tapping Screws (W/Flange) D4 x 25 [35]. Be careful not to mistake the screw positions.

Tapping Screws

(W/Flange) D4 x 20 (Black) [9]

Tapping Screws

(W/Flange) D4 x 25 [35]

(6) Mount the Carbon Brushes (1 Pair) [28] to the Housing Ass'y [20].

Ball bearing side

Washer (A) [14]

Loading...

Loading...