Maintenance

HON 380 gas pressure regulator with HON 673/674 controller 41

8.3 Starting maintenance

Risk of serious injury posed by pressurized components moving in an uncon-

trolled manner when handled improperly.

If not handled properly or in the event of a defect, gas can escape from pressur-

ized components under high pressure and cause serious injuries and even death.

Before you start working on these components:

Close all connections leading to the gas-carrying line.

Establish a depressurized status. Residual amounts of energy must be depres-

surized as well.

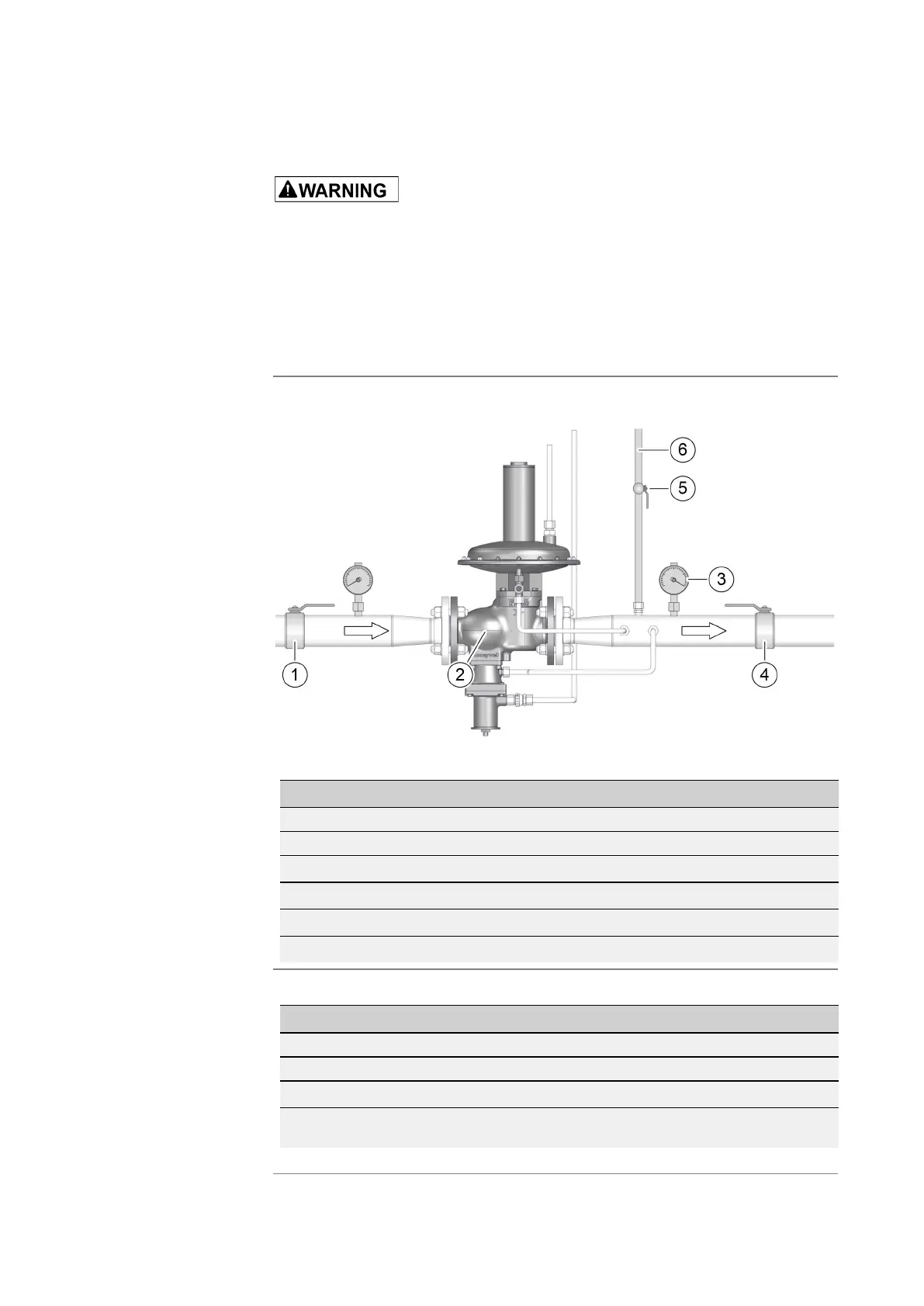

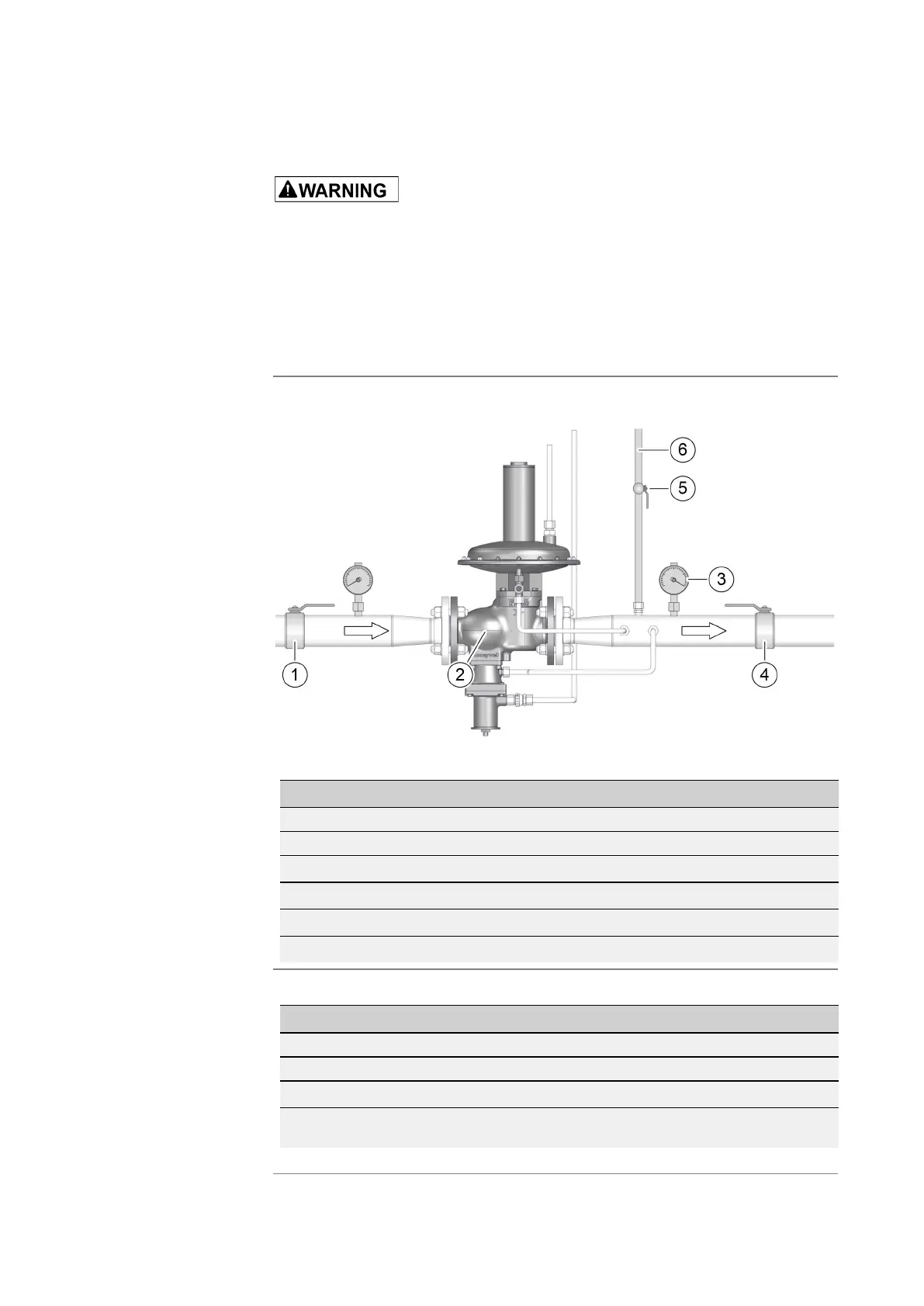

Schematic diagram using the RE1 DN50 and HON 673 as a reference:

The numbers have the following meaning:

No. Meaning

1 Inlet stop valve armature

2 Gas pressure regulator

3 Pressure gauge

4 Outlet stop valve armature

5 Valve for blowdown line

6 Blowdown line

Proceed as follows:

Step Description

1 Close the outlet stop valve armature (4).

2 Close the inlet stop valve armature (1).

3 Depressurize the gas pressure regulator.

4 Open the ball valve (5) in the blowdown line (6) to discharge the pressure be-

tween the inlet and the outlet valves.

Establishing the de-

pressurized status

Loading...

Loading...