RM7897A1002, RM7897C1000 7800 SERIES RELAY MODULES

3 66-1151

Wiring Subbase

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or equipment

damage.

Disconnect the power supply before beginning

installation. More than one disconnect may be

required.

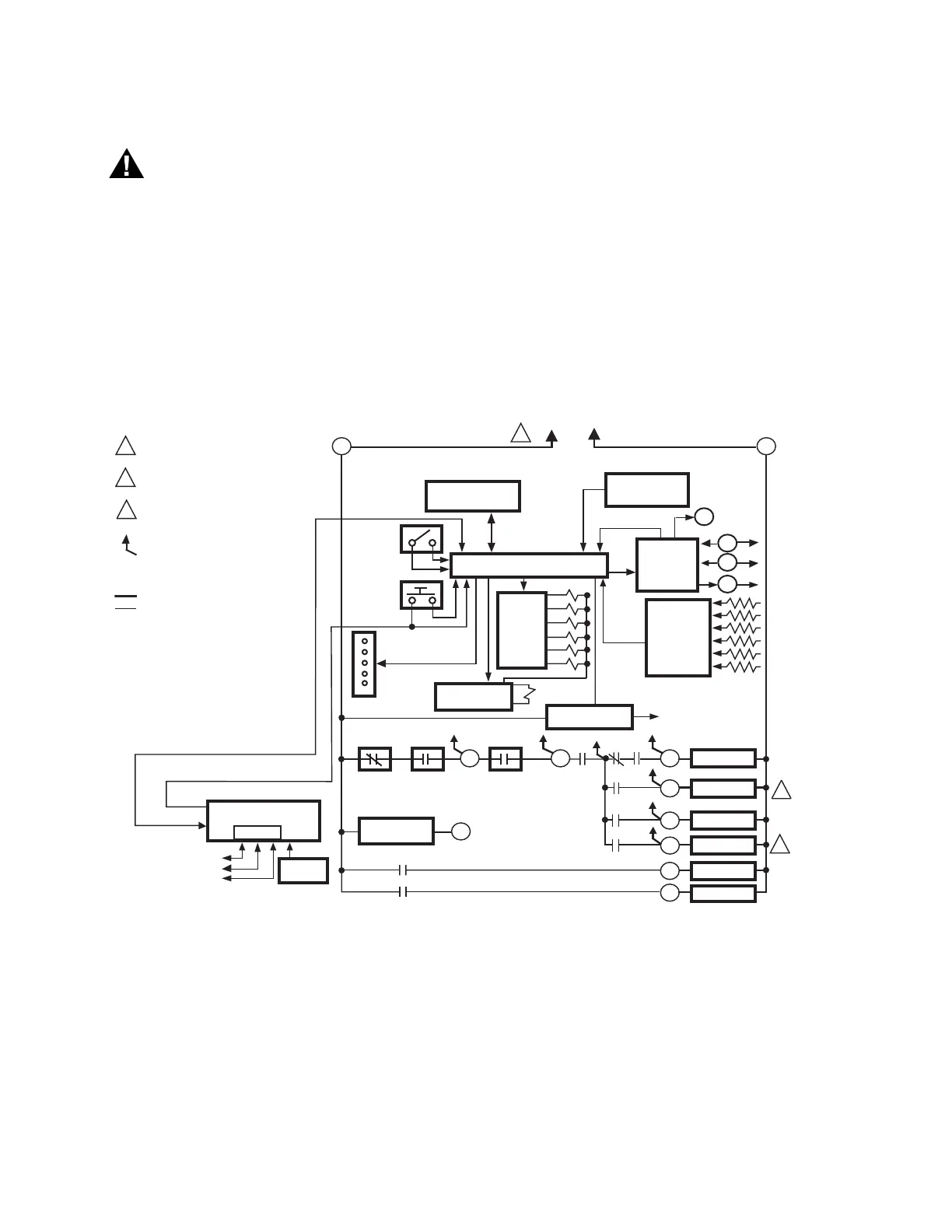

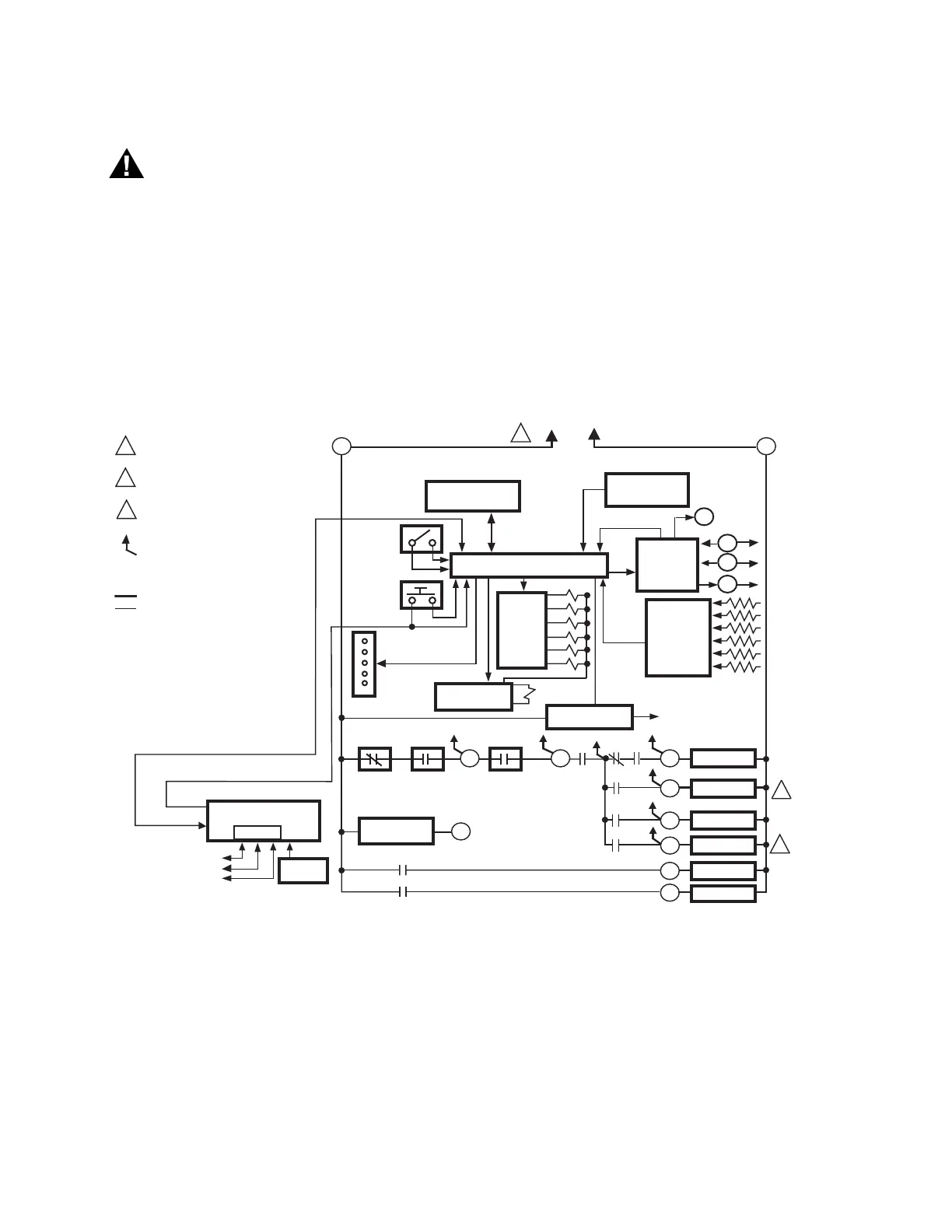

The internal block diagram of the RM7897A,C is shown in Fig.

1.

1. For proper subbase wiring and sequence chart, refer to

Fig. 2 and 3.

2. For remote wiring of the Keyboard Display Module, refer

to the Specifications for the Keyboard Display Module

(65-0288), Network Interface Unit (63-2278), Data

ControlBus™ Module (65-0091) or Extension Cable

Assembly (65-0131).

3. Disconnect the power supply from the main disconnect

before beginning installation to prevent electrical shock

and equipment damage. More than one disconnect can

be required.

4. All wiring must comply with all applicable electrical

codes, ordinances and regulations. Wiring, where

required, must comply with NEC, Class 1 (Line Voltage)

wiring.

5. For recommended wire size and type, see Table 1.

6. For recommended grounding practices, see Table 2.

Fig. 1. Internal block diagram of RM7897A,C (see Fig. 2 and 3 for detailed wiring instructions).

7. Recommended wire routing of leadwires:

a. Do not run high voltage ignition transformer wires

in the same conduit with the flame detector, Data

ControlBus Module™, or Remote Reset Module

wiring.

b. Do not route flame detector, Data ControlBus™

Module, or Remote Reset Module leadwires in

conduit with line voltage circuits.

c. Enclose flame detector leadwires without armor

cable in metal cable or conduit.

d. Follow directions in flame detector, Data

ControlBus™ Module, or Remote Reset Module

Instructions.

8. The KDM is powered from a low voltage, energy limited

source. It can be mounted outside of a control panel if it

is protected from mechanical damage.

NOTE: A 13 Vdc power supply must be used any time more

than one KDM is used.

CONFIGURATION

JUMPERS

MICROCOMPUTER

RESET

PUSHBUTTON

RUN/TEST

SWITCH

STATUS LEDs

PLUG-IN PURGE

TIMER CARD

SAFETY RELAY

CIRCUIT

POWER SUPPLY

OPTIONAL KEYBOARD

DISPLAY MODULE

PLUG-IN

FLAME

AMPLIFIER

RELAY

DRIVE

CIRCUIT

CONTROL

POWER

TEST

JACK

REMOTE

RESET

DDL

DDL

COMMUNICATIONS

INDICATES FEEDBACK SENSING

TO RELAY STATUS FEEDBACK

AND LINE VOLT INPUTS

FIELD WIRING

INTERNAL WIRING

IGNITION

PILOT

MAIN VALVE

1K

RELAY

STATUS

FEEDBACK

AND LINE

VOLTAGE

INPUTS

LIMITS

CONTROLLER

LOCKOUT

INTERLOCK

(INCLUDING

AIRFLOW SWITCH)

1K1 2K1 5K1

FLAME SIGNAL

TEST

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

RM7897A-INTERMITTENT PILOT.

RM7897C-INTERRUPTED PILOT.

RM7897A-INTERRUPTED PILOT.

RM7897C-DELAYED MAIN VALVE.

RS485

1

2

3

L1

(HOT)

L2

5

6

7

4K1

2K2

10

8

9

7K

6K

5K

4K

3K

2K

F

G

22

1

BLOWER

6K1

4

ALARM

3K1

3

L2

M22727A

1

2

120 VAC,

50/60 HZ

PREIGNITION

INTERLOCK

20

7K16

21

2

3

3

Loading...

Loading...