5. Deck clutch switch (Fig. 3-2) — this switch engages

the deck. Pull the switch up to engage and push switch

down to disengage the clutch.

IMPORTANT: Never engage clutch with engine

running at high rpm or when the deck is under load.

Clutch, belts or deck could be damaged.

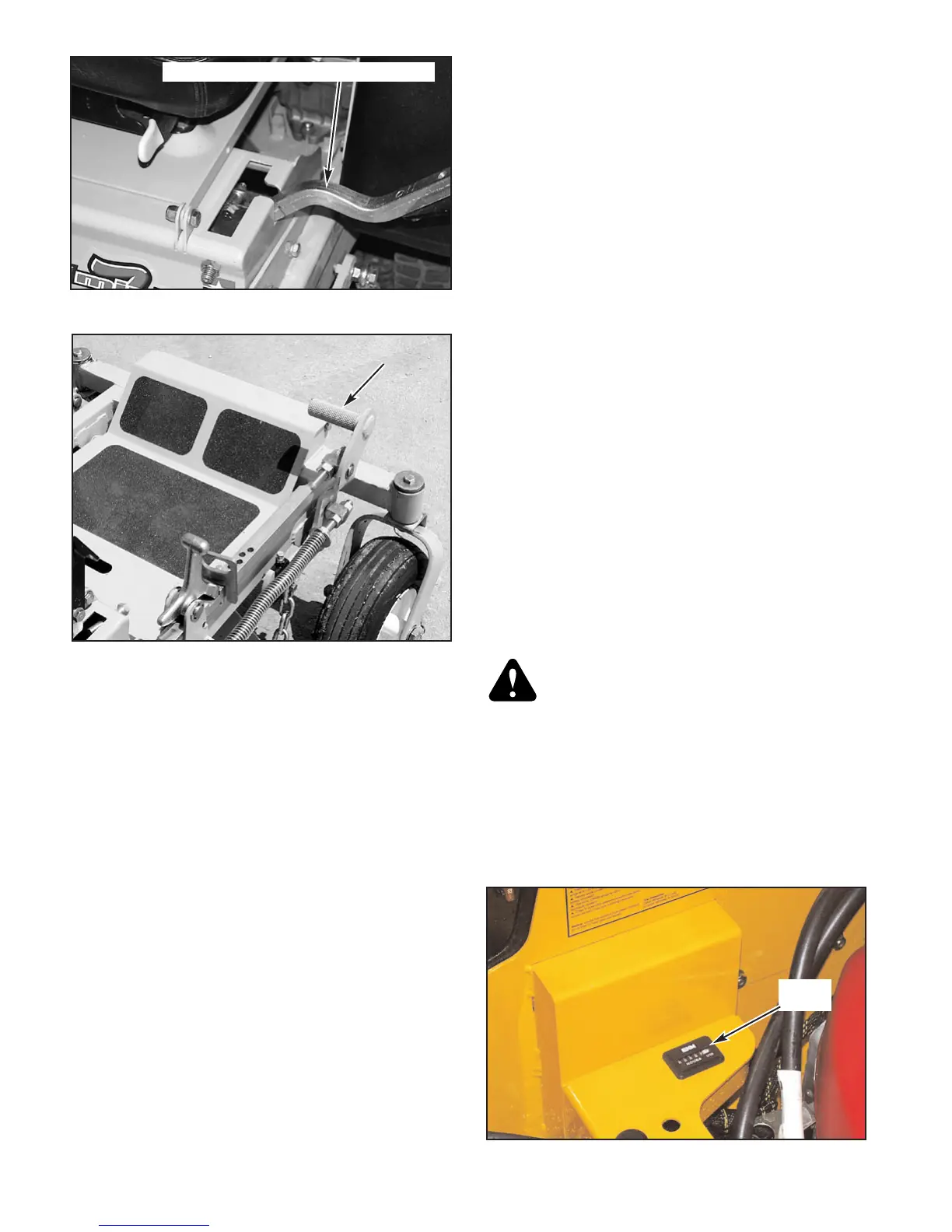

6. Deck lift pedal (Fig. 3-5) — the deck lift pedal is used

to raise or lower the deck. Push on the pedal to raise

the deck and then place the deck height locking pin

into the desired cutting height hole.

Push the deck lift pedal to raise the deck when going

over obstructions.

Instrumentation

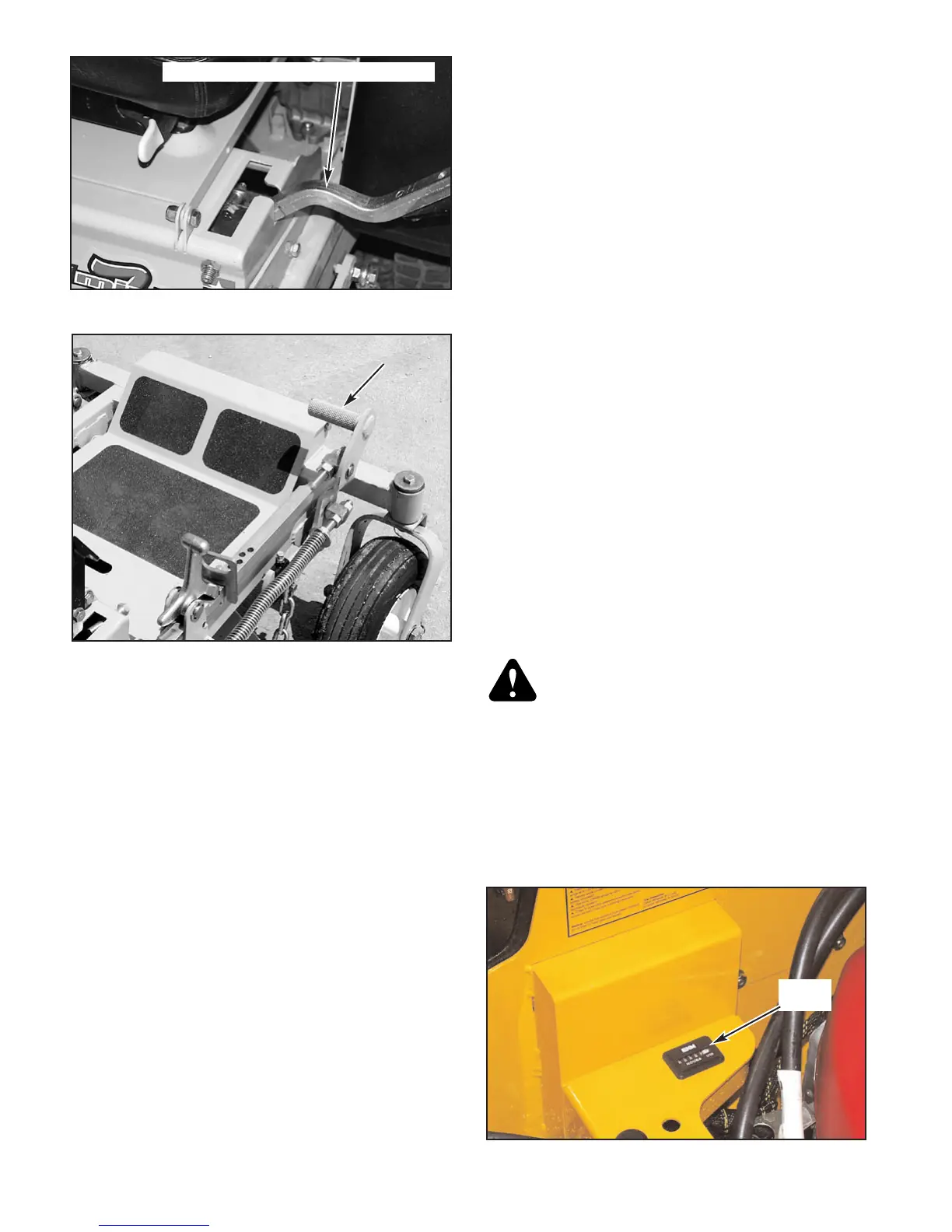

7. Electronic hour meter (Fig. 3-6) — registers 1/10

hour increments up to 9,999.9 total hours. Connected

to the ignition switch, the meter records the

accumulative time while the ignition key is switched to

the RUN position and the operator is on the seat.

8. Oil pressure light (Fig. 3-2) — this light comes on

when the ignition switch is placed in the RUN position

and stays lit until the engine is running and a safe oil

pressure is developed. If light comes on during

operation, shut engine off immediately and locate and

correct the problem.

Safety interlock system

The tractor is equipped with a safety start interlock

system consisting of the park brake switches, seat switch,

and deck clutch switch.

Check tractor safety start interlock system daily, prior to

operation. This system is an important tractor safety feature.

It should be repaired immediately if it malfunctions. The

machine incorporates a separate seat switch which will stop

the tractor engine when the operator is unseated for any

reason while the tractor is operating. This is a safety feature

designed to prevent runaway or accidental entanglement. To

inspect the system:

1. The operator must be on the seat when testing the seat

switch.

2. Set both control levers in the park brake position.

3. Start the engine and allow it to warm up to operating

temperature.

4. With the deck clutch switch down and the control

levers in the park brake position, slowly raise off of the

seat. The engine should continue to run.

5. With the deck clutch switch up and/or the control

levers in the neutral position, slowly raise off of the

seat. The engine should stop.

6. If the engine fails to stop when the deck clutch switch

is up or one or both of the control levers is up and the

operator is off the seat, check the function of the seat

switch. If the seat switch is not operating properly (is

not opening or closing) and if the cause can not be

determined, replace the seat switch.

If the problem can not be located, contact your Hustler

Dealer.

WARNING: The safety interlock system should

always function per steps 4 and 5. If it does not

function properly, it should be corrected

immediately. Do not operate machine without

properly functioning seat safety switch.

Engine starting

The Mini Z safety start interlock system is also designed

to protect the operator and others from accidental injury due

to unintentional engine starting. The engine starting motor

will not engage until:

302638 Rev 1/05

3-2

Figure 3-5

Deck lift

pedal

Figure 3-6

Hour

meter

Figure 3-4

Control lever in park brake position

Loading...

Loading...