2. Before installing a new element, inspect it by placing a

bright light inside and rotate the element slowly,

looking for any holes or tears in the paper. Also check

gaskets for cuts or tears. Do not attempt to use a

damaged element which will allow abrasive particles

to enter the engine.

3. Reinstall the dust cup. Make sure it seals all the way

around the air cleaner body, then tighten the clamps.

4. Check all fittings and clamps periodically for tightness

and inspect hoses for holes or cracks.

5. Periodically check the intake hose for signs of ingested

dust. Locate and repair the source of ingested dirt.

6. Never operate a machine without an air filter installed.

Air restriction indicator

Any unit with a Kawasaki engine will have an air

restriction indicator installed in the air cleaner. Fig. 4-13

Replace the element whenever the restriction indicator

shows reaches the change filter red line. Check the indicator

daily and replace element as needed or annually whichever

occurs first.

Reset the indicator by pushing in on the yellow button

after each element change. Fig, 4-13

A restriction indicator takes the guesswork out of air

cleaner servicing and allows you to safely benefit from the

filter’s optimum performance.

General engine maintenance

Detailed instructions and recommendations for break-in

and regular maintenance are specified in the Engine

Owner’s manual. Please refer to this manual for engine

servicing, lubricating oil levels with quality and viscosity

recommendations, bolt torques, etc. The engine warranty is

backed by the manufacturer. Special attention should be

paid to applicable data which will not be duplicated here.

4-12

302638 Rev 1/05

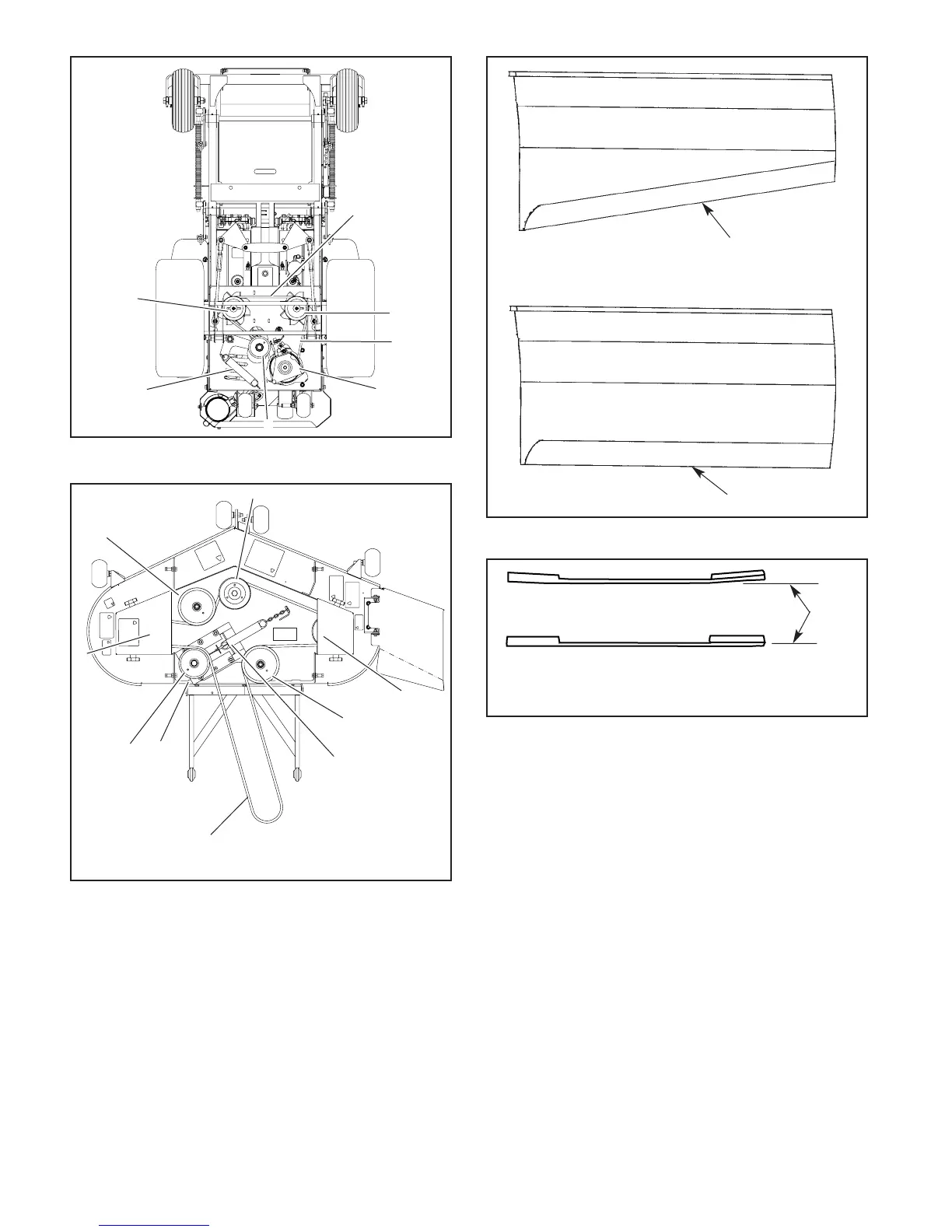

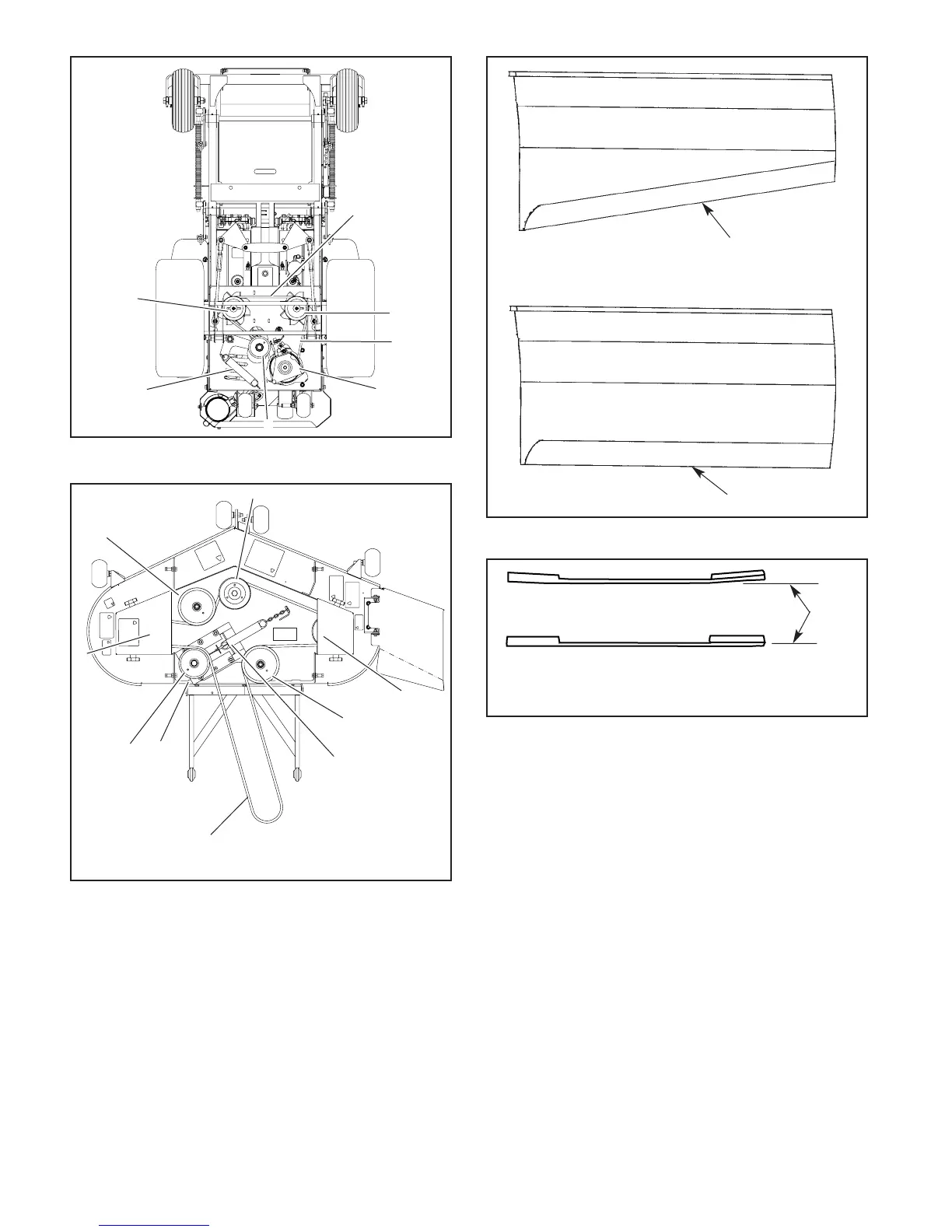

Figure 4-16

Resharpening Pattern

Do not sharpen to original pattern (below).

It is easier to get a straight cutting edge following

the resharpening pattern shown above.

Original Edge

Warped Blade (Replace)

Straight Blade

Comparison of Warped and Straight Blades

Cutting

Plane

Figure 4-17

Figure 4-15

1

Deck Belt Drive Layout

1. Spindle drive belt

2. Deck blade spindle pulley

3. Spindle belt tension idler

4. Spindle belt tension idler spring

(7.75" at operation)

5. Deck belt idler

6. Idler arm

2

2

2

6

4

5

3

5

Figure 4-14

1

2, 6

4

5

1. Pump belt

2. Engine pulley

3. Pump idler pulley

4. Pump idler arm

5. Pump pulley

6. Electric deck clutch

7. Pump idler spring

7

Viewed from

bottom for unit

5

3

Loading...

Loading...