127180 4-7 REV A

3. Adjust the right brake cleat so that the gap between it

and the tire is .25". Repeat for the left side. Figure 4-16

& Figure 4-17

4. Engage park brake lever. The park brake plate should

push in on the tire to prevent it from rotating.

If one of the brake cleats does not fully engage the tire

then it may be necessary to adjust the brake cleat until

it fully engages the tire.

Belts

Inspect belts frequently for wear and serviceability.

Replace a belt that shows signs of:

• severe cuts

• tears

• separation

• weather checking

• cracking

• burns caused by slipping.

Slight raveling of belt covering does not indicate failure,

trim ravelings with a sharp knife.

Inspect the belt pulley grooves and flanges for wear. A new

belt, or one in good condition, should never run against the

bottom of the groove. Replace the pulley when this is the

case, otherwise, the belt will lose power and slip excessively.

Never pry a belt to get it on a pulley as this will cut or

damage the fibers of the belt covering.

Keep oil and grease away from belts, and never use belt

dressings. Any of these will destroy the belt composition in a

very short time.

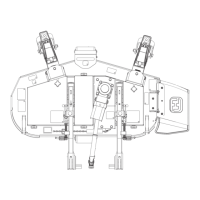

Hydraulic Pump Belt Adjustment

The transmission drive belt tension remains constant by

means of a tension idler and spring. The spring tension

should be such that the belt does not slip under normal

operating load conditions, assuming the belt is not

excessively worn or damaged. As the belt stretches and

wears in, adjustment may become necessary.

The proper belt tension is achieved when the tension

spring is stretched to the appropriate dimension when

measured from the outside of one hook to the outside of the

other hook. Figure 4-18

To increase belt tension, loosen the jam nut on the eye

bolt. Then, tighten the nut on the eyebolt until the

appropriate dimension is attained. Lock the eyebolt in place

by tightening the jam nut. Figure 4-18

IMPORTANT: Do not over tension the spring to compen-

sate for a badly worn belt or pulley.

Inspect the belt every 100 hours and replace as needed.

Replace the belt every 400 hours or every two (2) years

whichever comes first.

48"/52"/60" mower, right side shown

A. Carriage bolts

B. Brake cleat

C. Slot

D. Brake pivot

Figure 4-16

60" mower, right side shown

A. Carriage bolts

B. Brake cleat

C. Slot

D. Brake pivot

Figure 4-17

MOWER SIZE SPRING LENGTH

36"

8.25" ± .125"

(209.55 mm ± 3.18 mm)

48"/52”/60”

7.80” ± .125”

(198.12 mm ± 3.18 mm)

If the pump belt fails, loss of steering control will

occur especially when operating on a slope. If you

lose steering control while operating the mower, turn

the engine off and, if on a slope, step off of the

operator’s platform to the uphill side. Inspect the

machine and involve your Hustler

®

Dealer to resolve

the problem before continuing to operate.

Loading...

Loading...