2

Thick metal cutting techniques overview

Edge start

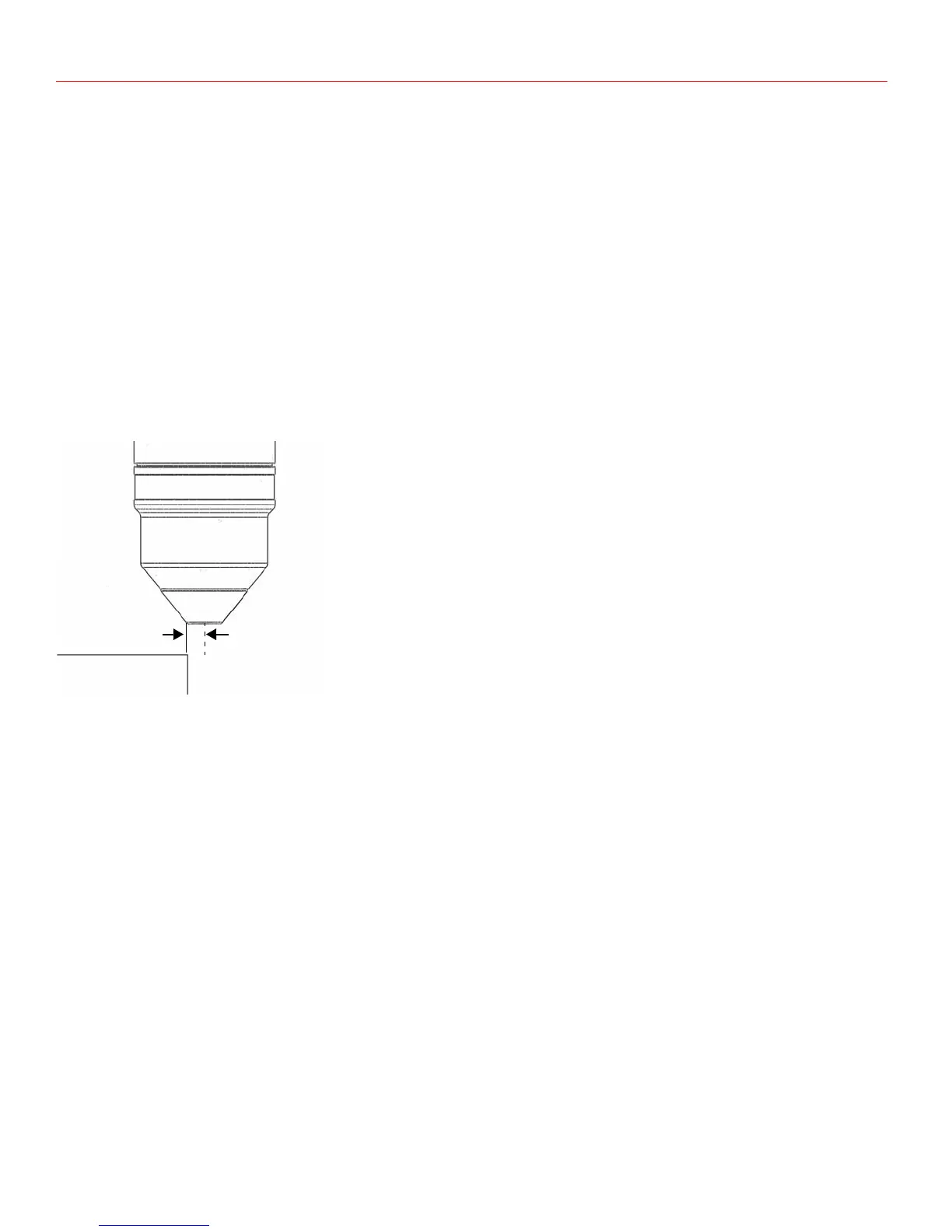

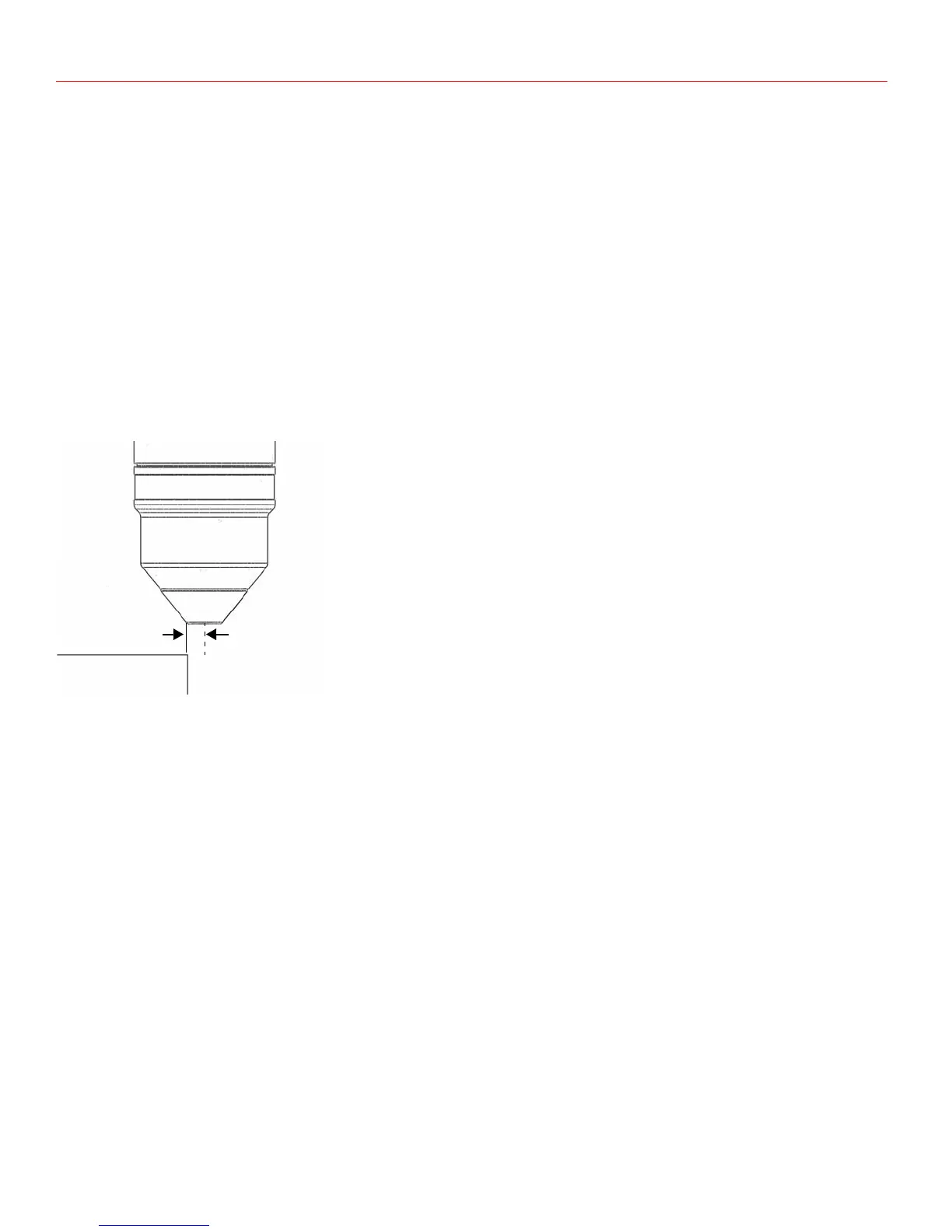

Positioning

Proper positioning of the torch is important to allow the

molten metal (or melt) to carry down the majority of the

thickness (especially when starting on a rough edge). Set

the height of the torch to the cut height listed in the cut

chart, which you can find in the Operation section of the

HPR800XD Instruction Manual (806500 [Auto Gas] or

806490 [Manual Gas]). Place the torch center-line about

0.25 inches (6 mm) from the workpiece edge. The edge of

workpiece should be approximately lined up with the shield

face diameter, as shown in Figure 1.

Figure 1 – Edge start positioning

Motion (or pierce) delay

An adequate motion delay must be used to allow enough

time for the arc to melt the majority of the edge prior to

motion being initiated. Suggested motion delays for 800 A

thick metal cutting are listed in the cut charts in the

HPR800XD Instruction Manual. These times may need to

be adjusted based on your application.

Initial cut speed (lead-in speed)

A reduced cut speed should be used for at least the first

1 inch (25 mm) of the cut before traveling at the full cut

speed. The recommended initial cut speed should be 75%

of the full cut speed.

Cornering

Special cornering considerations may be necessary when

working with thick metal due to the extreme lag of the tail

(bottom portion) of the arc. If no technique is used, the cut

edge may lose its form, especially near the bottom of the

cut. Use one of the following methods:

• Rounding corners

•Corner delay

• Corner slow-down

Rounding corners

One method to maintain edge form is to round off corners of

90 degrees or less. In general, the radius should be equal to

or greater than the kerf value (larger is better).

Corner delay

Allow the motion to dwell in the corner for approximately one

second to allow the arc tail to “catch up.”

Corner slow-down

Approximately 1 inch (25 mm) before entering the corner,

slow down the cut speed to 75% of the full cut speed.

Maintain 75% of the cut speed for approximately 1 inch

(25 mm) after the corner before resuming the full cut speed.

Approximately 0.25 inches (6 mm)

Loading...

Loading...