5

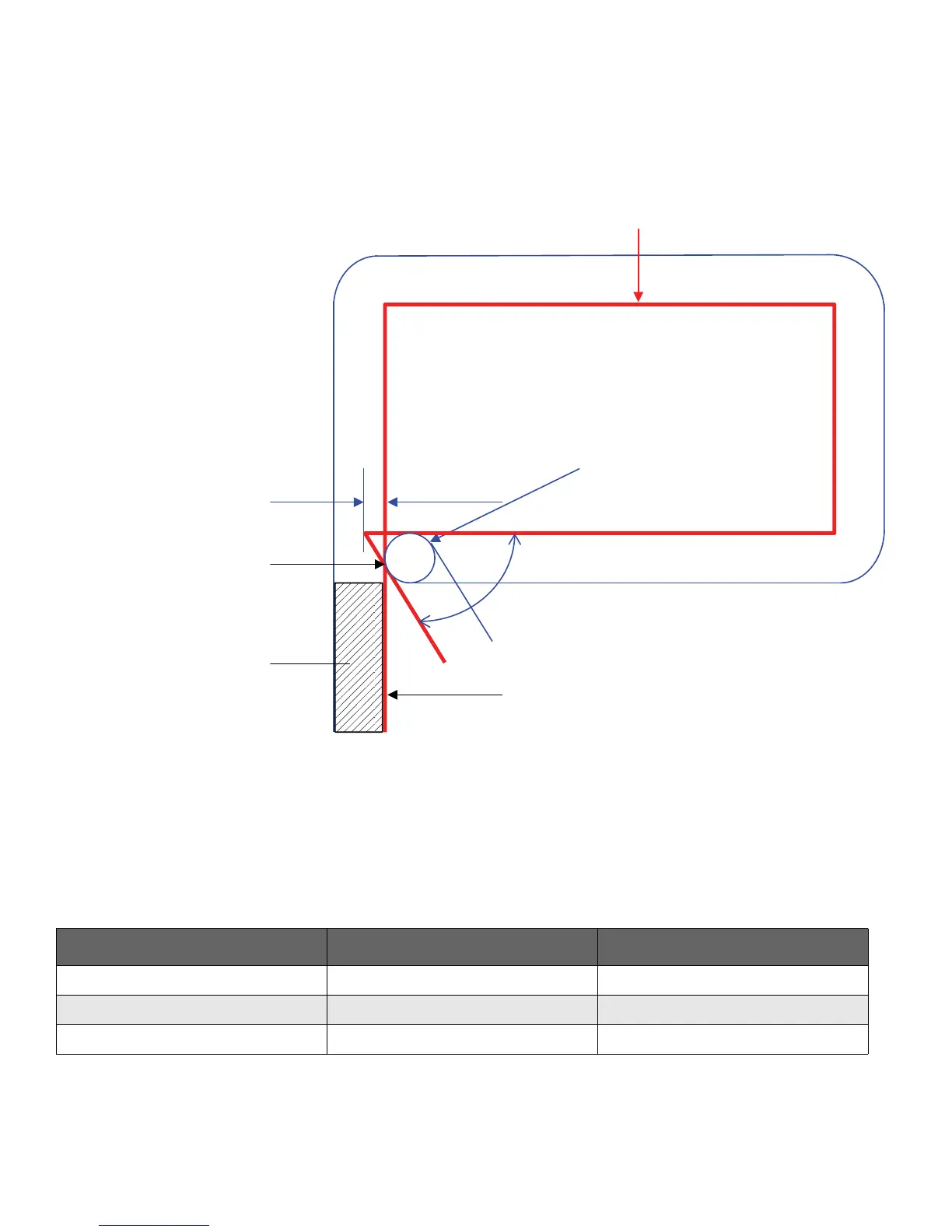

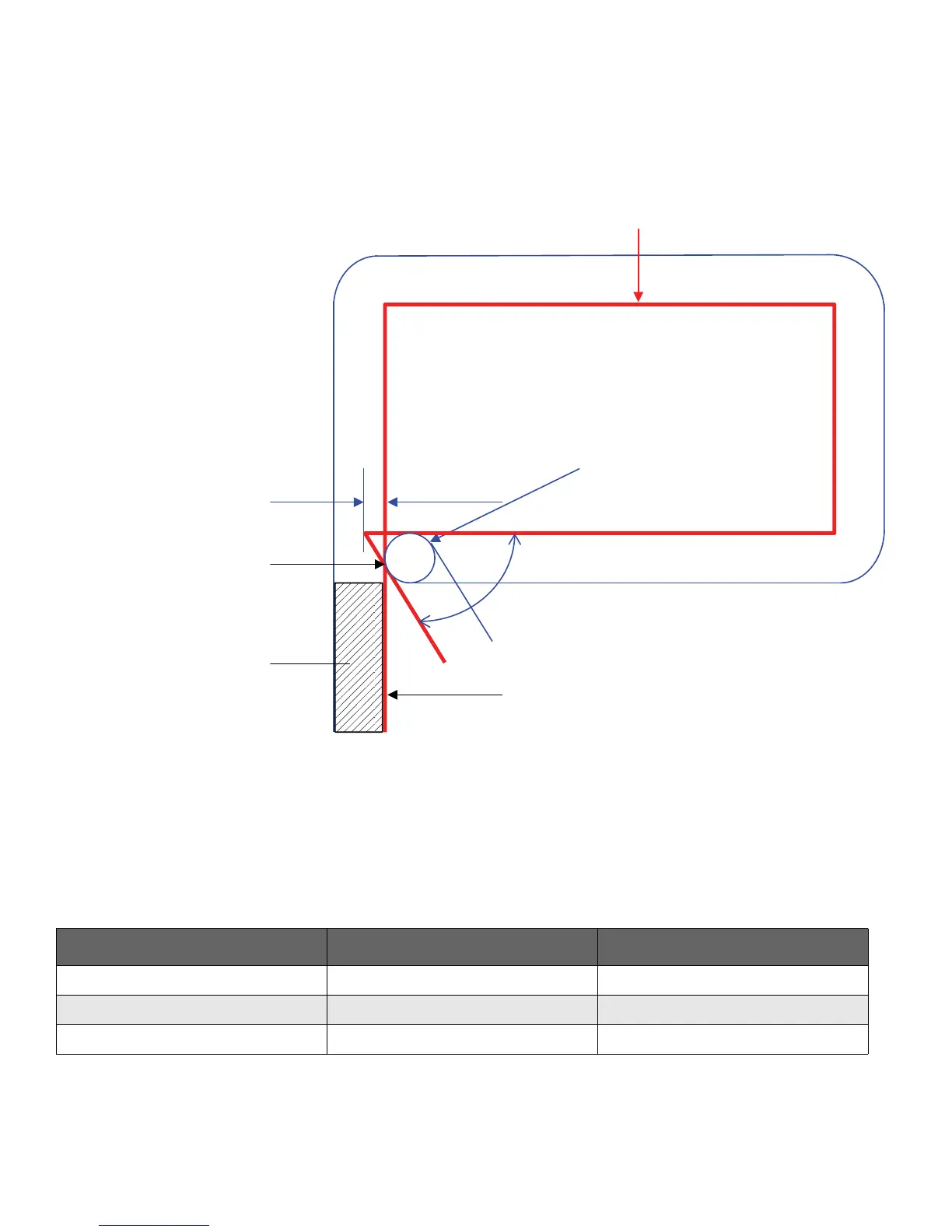

Overshoot

In order for the leading kerf edge to enter the lead-in edge

(with kerf compensation active), the programmed path must

overshoot by some distance (see Figure 6).

Figure 6 – Overshoot definition

This overshoot distance can be calculated using the

following equation:

Overshoot = K

where K is kerf, α is angle, and Correction is an additional

factor necessary to ensure adequate penetration of the arc

into the lead-in section. The Correction factor values for

5–6.25 inches (125–160 mm) are shown in Table 1.

As an example, if α = 60° for a thickness of 6 inches, the

overshoot value is:

K(0.866-0.5+0.25) = 0.68(0.616) = 0.419 inches

Lead-in

Leading kerf edge

Overshoot distance

Kerf width (K)

Lead-in edge

α

Programmed path

1

2

α

2

---

tan

------------------------ -

1

2

---

– Correction+

Table 1 – Correction factors.

Thickness Kerf Correction Factor

5 inches (125 mm) 0.530 inches (13.43 mm) 0.30

6 inches (150 mm) 0.680 inches (17.27 mm) 0.25

6.25 inches (160 mm) 0.700 inches (17.78 mm) 0.25

Loading...

Loading...