HYDRAULIC OIL

Using dipstick, measure oil level, and oil if

necessary.

When changing hydraulic oil, clean

suction strainer(screwed into outlet port

pipe) and line filter(screwed into inlet pipe).

Line filter uses paper element, so replace

periodically(every 6 months or 1000

hours)

6-22

GROUP 2 OPERATIONAL CHECKS AND TROUBLESHOOTING

1. OPERATIONAL CHECKS

CHECK ITEM

Check visually for deformation, cracks or

damage of rod.

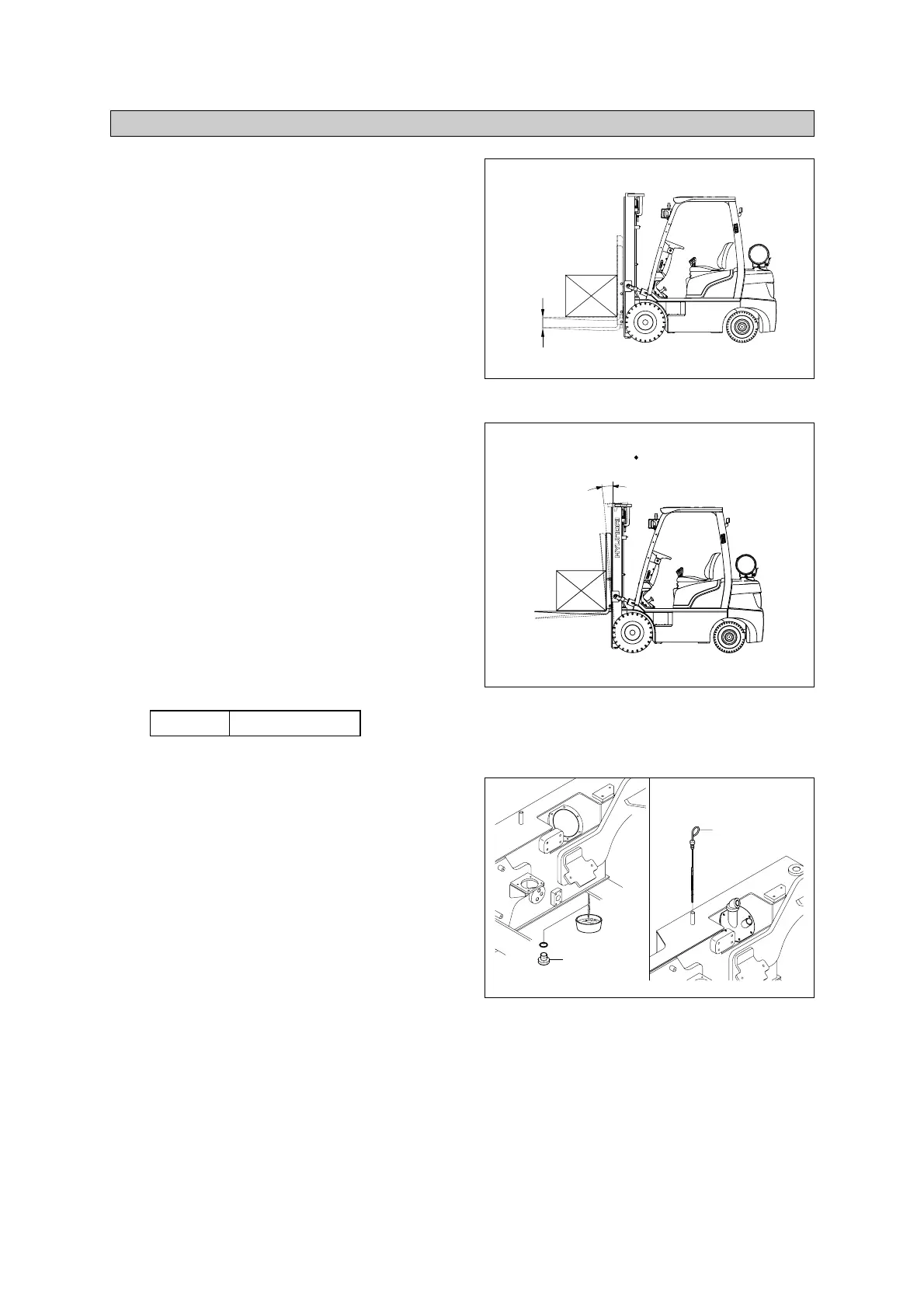

Set mast vertical and raise 1m from

ground. Wait for 10 minutes and measure

hydraulic drift(amount forks move down

and amount mast tilts forward).

Â

CCheck condition

- Hydraulic oil : Normal operating temp

- Mast substantially vertical.

- Rated capacity load.

Â

Hydraulic drift

- Down(Downward movement of forks)

: Within 100

mm

(3.9

in

)

- Forward(Extension of tilt cylinder)

: Within 5

Á

If the hydraulic drift is more than the

specified value, replace the control valve

or cylinder packing.

Check that clearance between tilt cylinder

bushing and mounting pin is within

standard range.

(1)

(2)

(3)

1

1)

2)

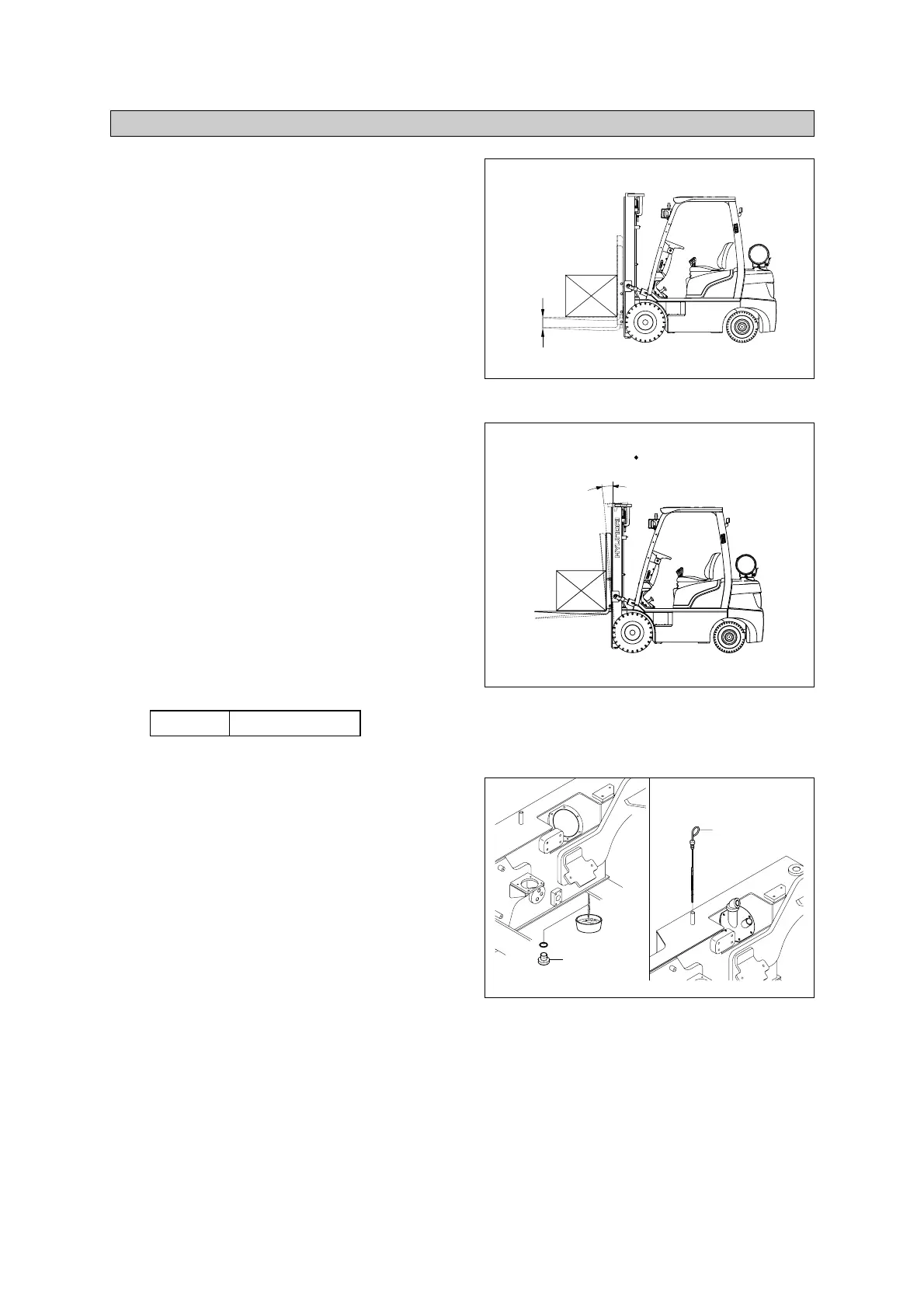

CONTROL VALVE

Raise forks to maximum height and

measure oil relief pressure.

Check that oil relief pressure is 190

kgf/cm

2

.

(2702

psi

)

15L7AHS18

15L7AHS19

15L7MHS20

3)

(1)

Loading...

Loading...