8-4

GROUP 2 OPERATIONAL CHECKS AND TROUBLESHOOTING

GROUP 2 OPERATIONAL CHECKS AND TROUBLESHOOTING

1. OPERATIONAL CHECKS

FORKS

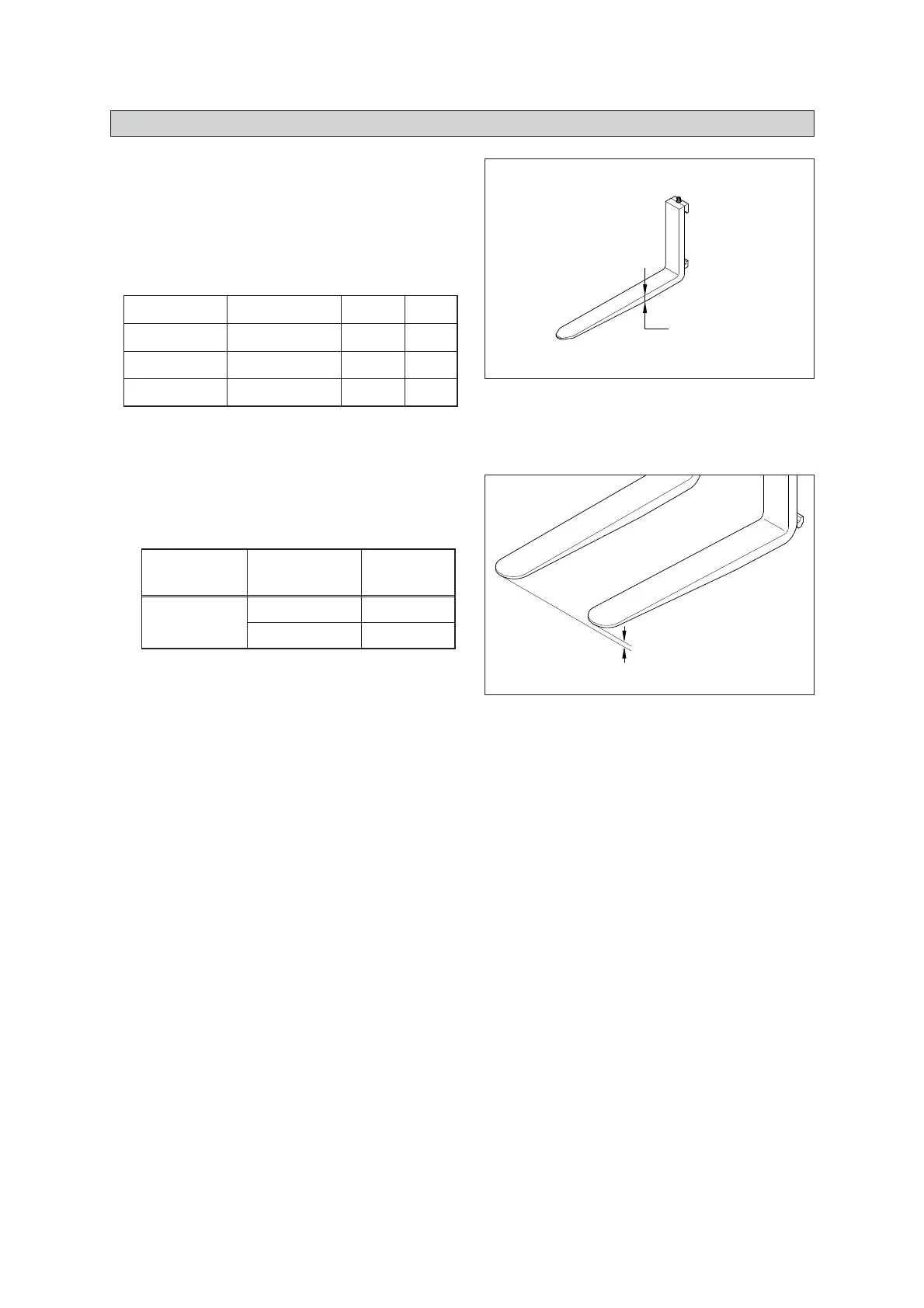

Measure thickness of root of forks and

check that it is more than specified value.

EX :

ℓ

=1800

mm

(71

in

)

1)

(1)

Thickness

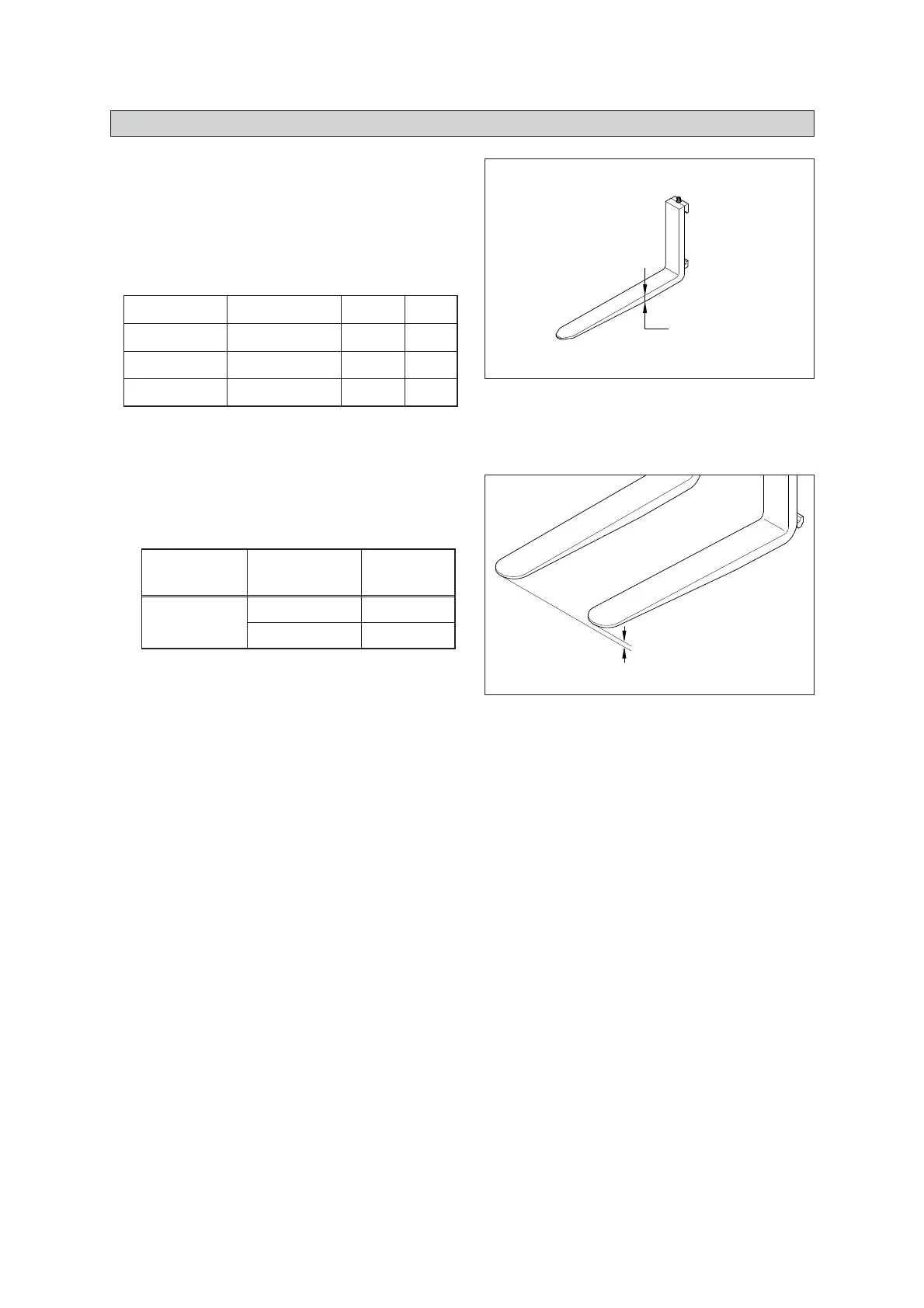

Set forks in middle and measure out of

parallel and difference in height at the top of

forks.

2)

STD Fork assy Applicable model

110D-7A

130D-7A

61FT-70342

61FT-71440

Standard

75(3.0)

90(3.5)

Limit

68(2.7)

80(3.2)

mm

(

in

)

2. MAST

Check for cracks at mast stay, tilt cylinder bracket, guide bar, fork carriage and roller shaft weld.

Check visually or use crack detection method. Repair any abnormality.

Set mast vertical, raise forks about 10

cm

from ground and check front-to-rear clearance and left-to-

right clearance between inner mast and fork carriage, and between outer mast and inner mast.

Use these figures to judge if there is any play at roller or rail.

·

Front-to-rear clearance : Within 2.0

mm

(0.08

in

)

·

Left-to-right clearance : Within 2.5

mm

(0.10

in

)

Check that there is an oil groove in bushing at mast support.

Set mast vertical, raise forks about 10

cm

from ground, and push center of lift chain with finger to

check for difference in tension.

If there is any difference in tension, adjust chain stopper bolt.

Check visually for abnormalities at thread of chain anchor bolt, and at contact surface between

chain wheel and chain.

Rotate chain wheel by hand and check for any play of bearing.

1)

2)

3)

4)

5)

D507FK01

Most force is concentrated at root of fork

and at hook, so use crack detection method

to check cracks.

3)

Difference in height

at tip of forks

D255FK02

61FT-70143

160D-7A 95(3.7)

85(3.3)

Model

Fork length

(

mm

)

110D-7A

130D-7A

160D-7A

below 1500

equal or above 1500

3

6

Height difference

(

mm

)

Loading...

Loading...