16

INSTALLING THE FLUE

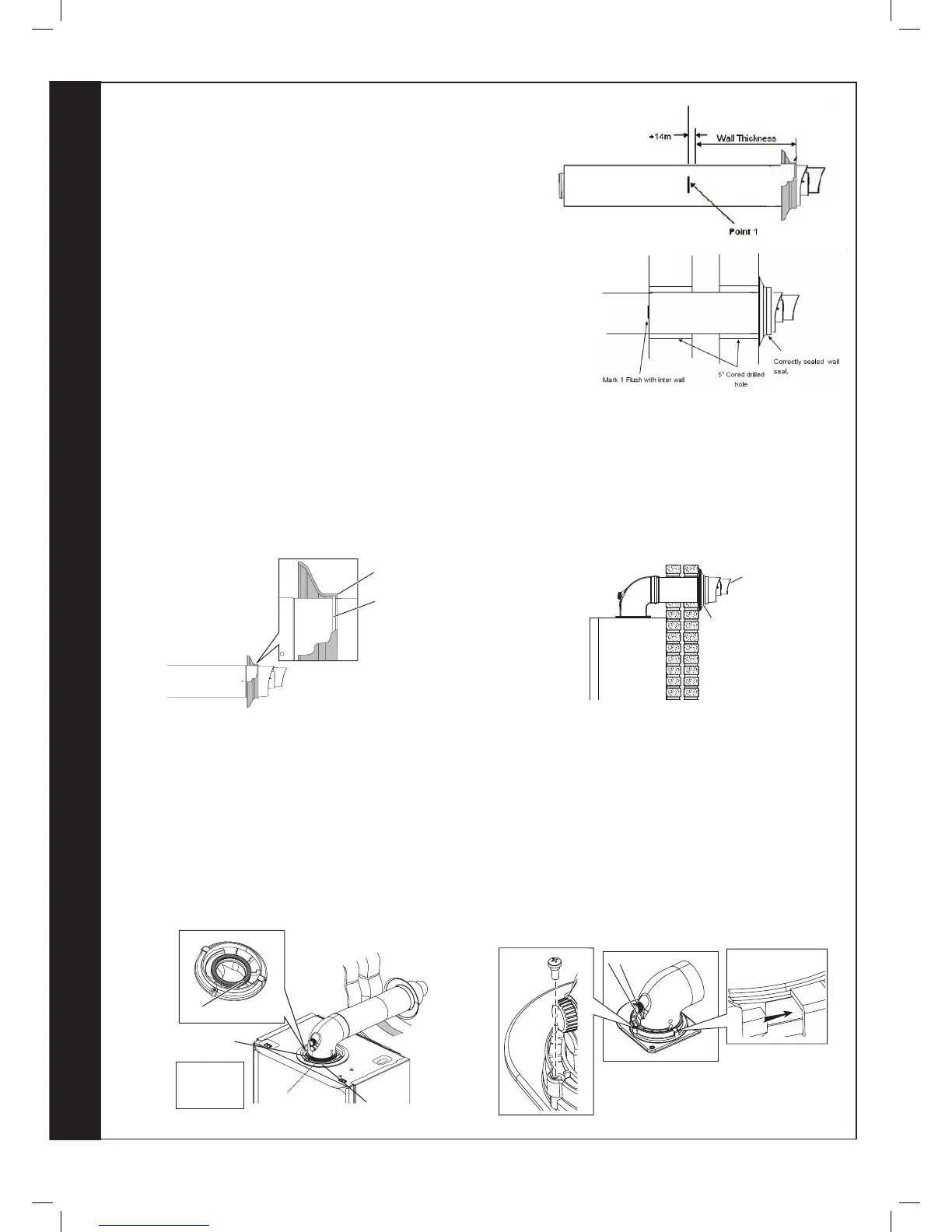

FITTING FLUE THROUGH THE WALL

1. Measure wall thickness and add 14mm.

2. Measure from the outer terminal lip towards the end of outer ue, place a

small location mark at the dimension acquired at point 1.

3. Fit external black wall seal ensuring the inside of the outer lip is in contact

with the terminal lip you have been measuring from (see g 1)

4. For an internal t, place ue terminal in the centre of the 5” drilled hole in

the wall. Apply pressure and lightly move the ue left to right or up and

down. This will cause the outer ange to fold in and allow the ue to pass

through the wall.

5. Push through a further 65mm. This will allow the outer ange to return to

its original shape.

6. Pull back the ue until the location mark point 1 is level with the internal

face of the wall.

Note. If the location mark is not visible then the ue is not pulled back far

enough to obtain the correct seal. If the location mark has passed the face

of the wall the ue has been pulled to far back and the outer wall seal will

have been dislodged from its mounting and will need to be retted.

7. Ensure the seam and the outlet terminal are at the top and tted as shown.

Note. If less than 50% of the length of the ue is internal the ue should be

tted from outside.

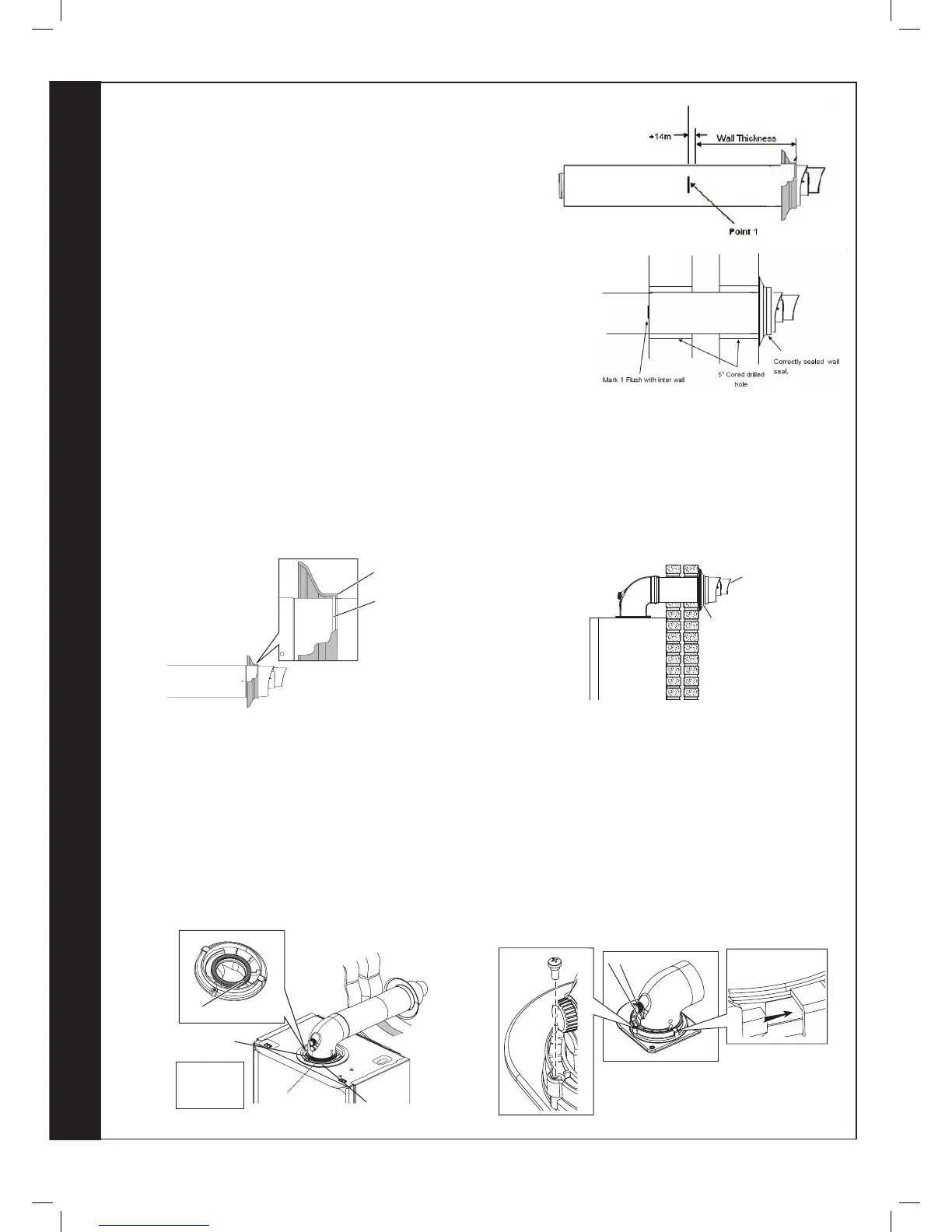

FITTING THE TURRET - Ensurethecondensetrap/siphonislledwithwater

1. Ensure the rubber seal is tted correctly on the appliance manifold and that all ue seals are undamaged.

2. Hold the ue rmly and push the turret on until it has travelled 30mm on to the ue pipe and is fully engaged. Make sure the

ue has not rotated or moved forward during tting and the ue seam is upper most.

3. Push the turret into the manifold ensuring the upper plastic lip is ush with the top of the manifold.

4. Fully engage the clamp location section into the manifold location holes. Rotate down on to turret ange.

5. Secure clamp to appliance using securing screw.

6. Ensure all sample points are accessible and all sample plugs and caps are tted.

Ensure lip of wall seal is positioned

Loading...

Loading...