3

50

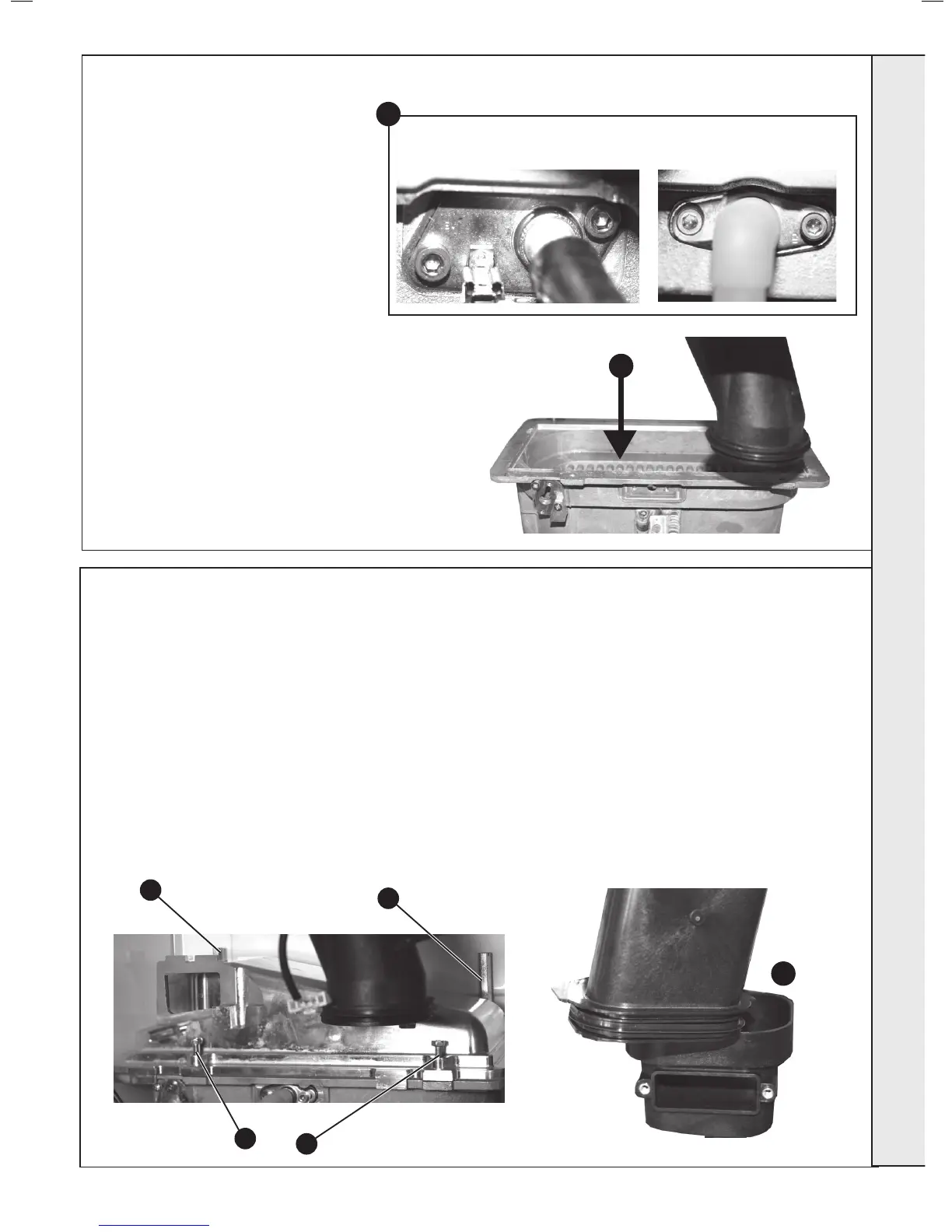

CLEANING THE HEAT EXCHANGER

Note:

is fully drained before cleaning. Refer to

Frame 49.

1. Remove ignition and ame detection

electrodes. Refer to Frames 57 & 58.

2. It is advisable to replace the sump cover

prior to the water ush process.

3. Thoroughly ush the heat exchanger

by pouring water into the top of the

combustion chamber ensuring the full top

area is covered.

4. Remove the sump cover and clean loose

deposits from the sump.

5. Inspect the ignition and detection

electrodes. Ensure that they are clean

and in good condition - replace if

necessary.

6. Re-t the ignition and ame detection

electrodes, ensuring that both earth tabs

are tted to ignition electrode.

7. Check that the ignition and detection gaps

are correct. Refer to Frames 57 & 58.

1

Ignition Electrode

Flame Detection

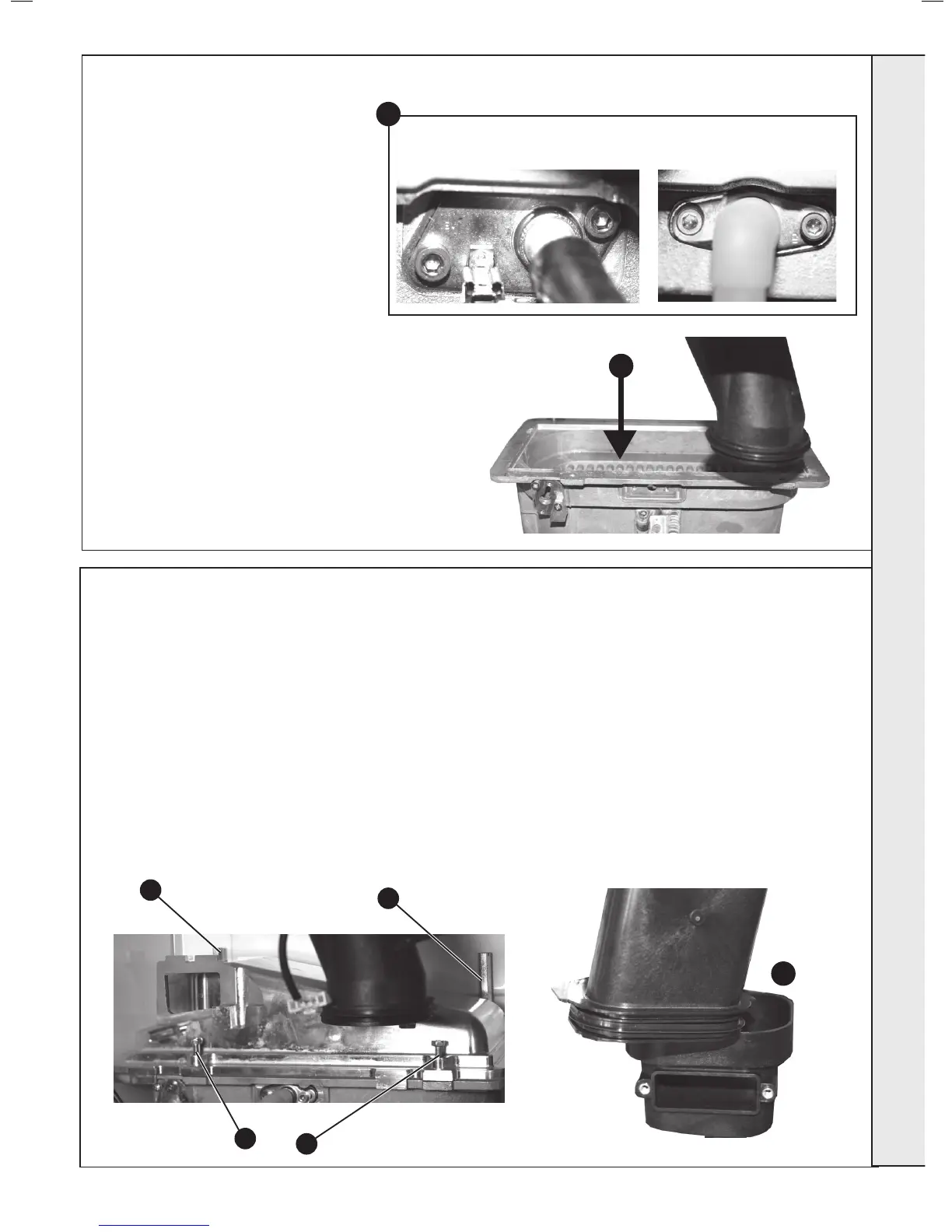

Reassemble the boiler in the following order:

1. Ensure that the condensate trap/siphon is full of water.

2. Ret the burner ensuring the sealing gasket is correctly

positioned and free from damage (tighten the 4 xing

screws in the sequence shown below - A,B,C,D).

3. Ret the fan / venturi assembly ensuring the retaining

tabs are correctly positioned and the sealing gasket is

correctly positioned and free from damage.

4. Reconnect the fan electrical leads.

5. Remove the sump cover and ret the lower ue manifold

as shown.

51

REASSEMBLY

5

A

6. Ret the sump cover.

7. Ret the boiler front panel.

IMPORTANT. Ensure that the boiler front panel is

correctly tted and that a good seal is made.

8. Swing the control box back into its working position and

secure.

9. Turn on the gas supply at the gas service cock.

10. Reconnect the electrical supply.

11. Check operation of the boiler. Refer to Frames 41 & 42.

B

D

C

SERVICING

Loading...

Loading...