Goodrive20-EU series VFD Communication protocol

119

In ladder logic, CKSM calculated the CRC value according to the frame with the table inquiry.

The method is advanced with easy program and quick calculation speed. But the ROM space

the program occupied is huge. So use it with caution according to the program required space.

7.2.3 ASCII mode

Communication protocol belongs to hexadecimal system. The meaning of message

character in ASCII: "0"…"9", "A"…"F", each hex is represented by the ASCII

message corresponds to the character.

Starting bit, 7/8 data bit, check bit and stop bit. The data formats are listed as

below:

11-bit character frame:

In ASCII mode, the frame header is ":" ("0*3A"), frame end is "CRLF" ("0*0D" "0*0A") by

default. In ASCII mode, all the data bytes, except for the frame header and frame end, are

transmitted in ASCII code mode, in which four high bit groups will be sent out first and then,

four low bit groups will be sent out. In ASCII mode, the data length is 8 bit. As for 'A' – 'F', its

capital letters is adopted for ASCII code. The data now adopts LRC checkout which covers

slave address to data information. The checksum equals to the complement of the character

sum of all the participated checkout data.

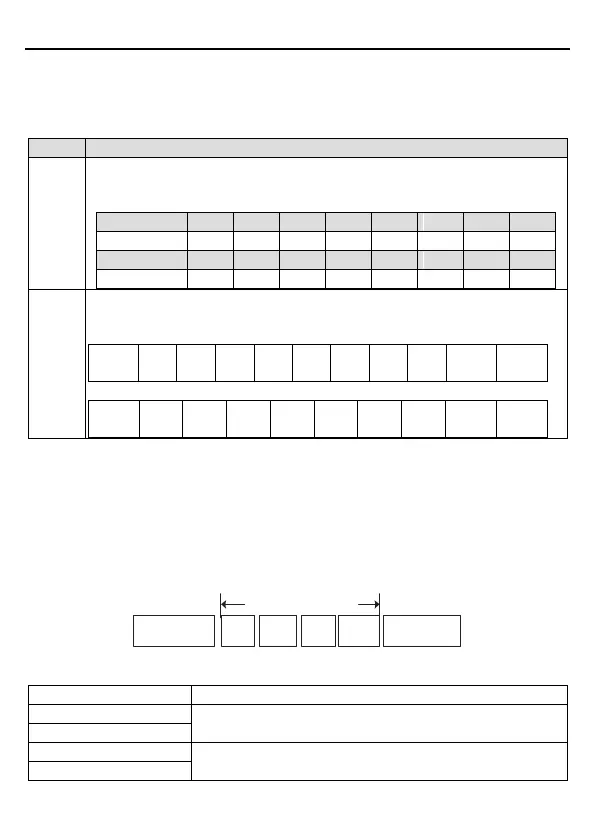

ASCII data frame format

Modbus message

Starting character:

“0x3A”

Slave

address

Function

code

Data

Checkout

Ending character:

“0*0D”“0*0A”

Standard structure of ASCII frame:

Communication address:

8-bit address is formed by the combination of two ASCII codes

Function code:

8-bit address is formed by the combination of two ASCII codes

Loading...

Loading...