Installation

6 720 643 409 (2010/03)

28

9 Installation

9.1 Collector system

Installation and filling

Installation and filling of the collector system should

comply with applicable laws and regulations. Soil used

for refilling around the collector hose may not contain

stones or other sharp objects. Pressure test the

collector system before refilling to ensure that the

system is airtight.

When cutting the collector, it is important that no dirt or

gravel enters the system. This can cause stoppages in

the heat pump and damage components.

Filling unit

A filling unit is included in the delivery and should be

installed close to the collector circuit inlet.

Expansion vessel, safety valve, pressure gauge

The expansion vessel, safety valve and pressure gauge

are to be provided by the dealer.

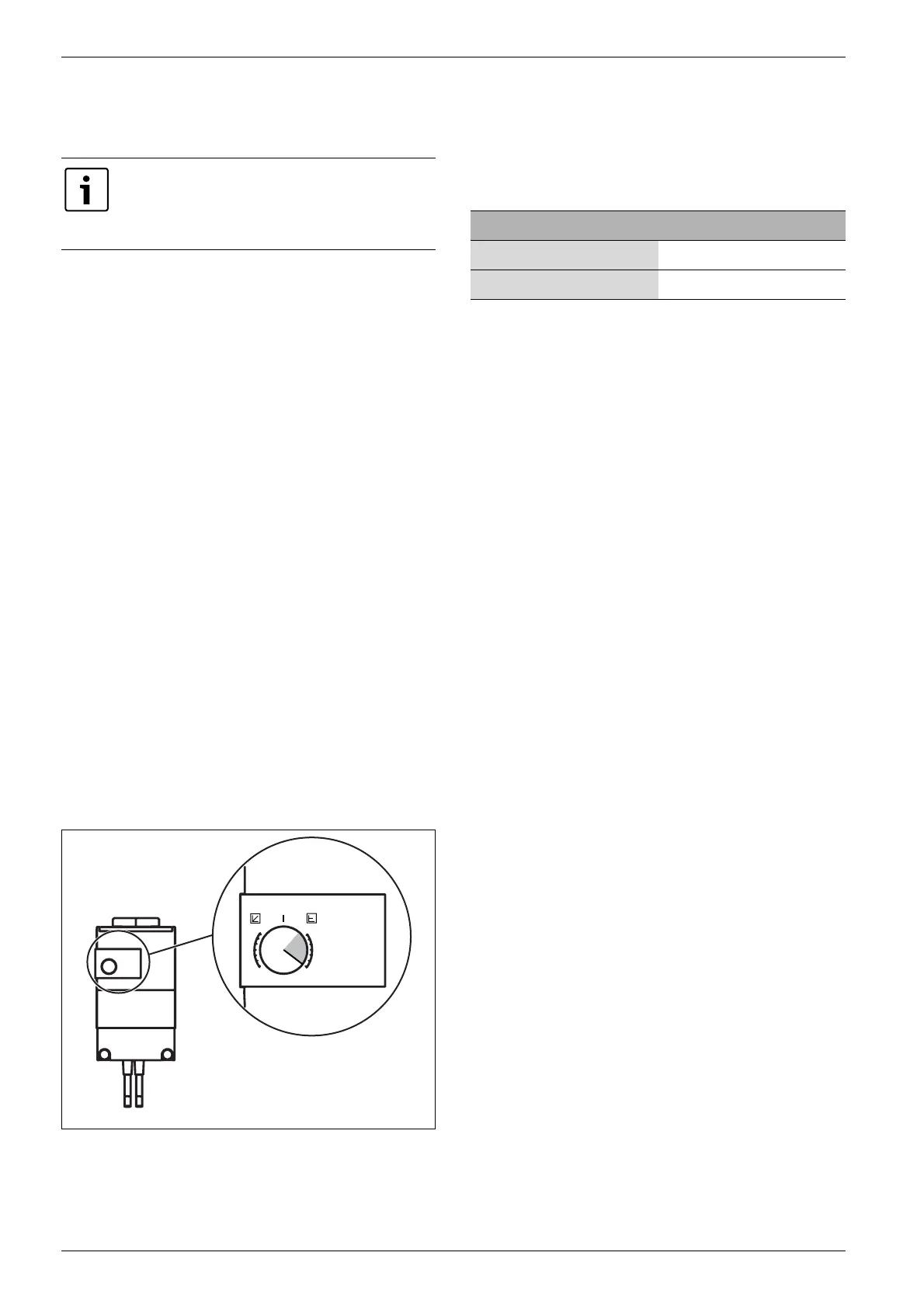

Heat transfer fluid pump

Factory setting for the collector circuit pump is max (Æ

Image 19). The setting may need to be adjusted to

achieve the correct delta value (Æ Chapter 18.4). The

value must lie within the grey area. To adjust the value,

turn the dial.

Fig. 19

Membrane expansion vessel in the collector circuit

Select membrane expansion vessel according to:

Antifreeze/Corrosion preventative

Freeze protection to -15 °C should be ensured. We

recommend the primary use of bio-ethanol, otherwise

propylene glycol.

Only qualified installers may carry out the

installation. The installer must follow

applicable rules and regulations and

recommendations from the supplier.

min

max

min

max

6 720 641 855-34. 1I

ext. in

Model Volume

E6-E11, C6-C11 12 litres

E14 - E17 18 litres

Tab. 18

Loading...

Loading...