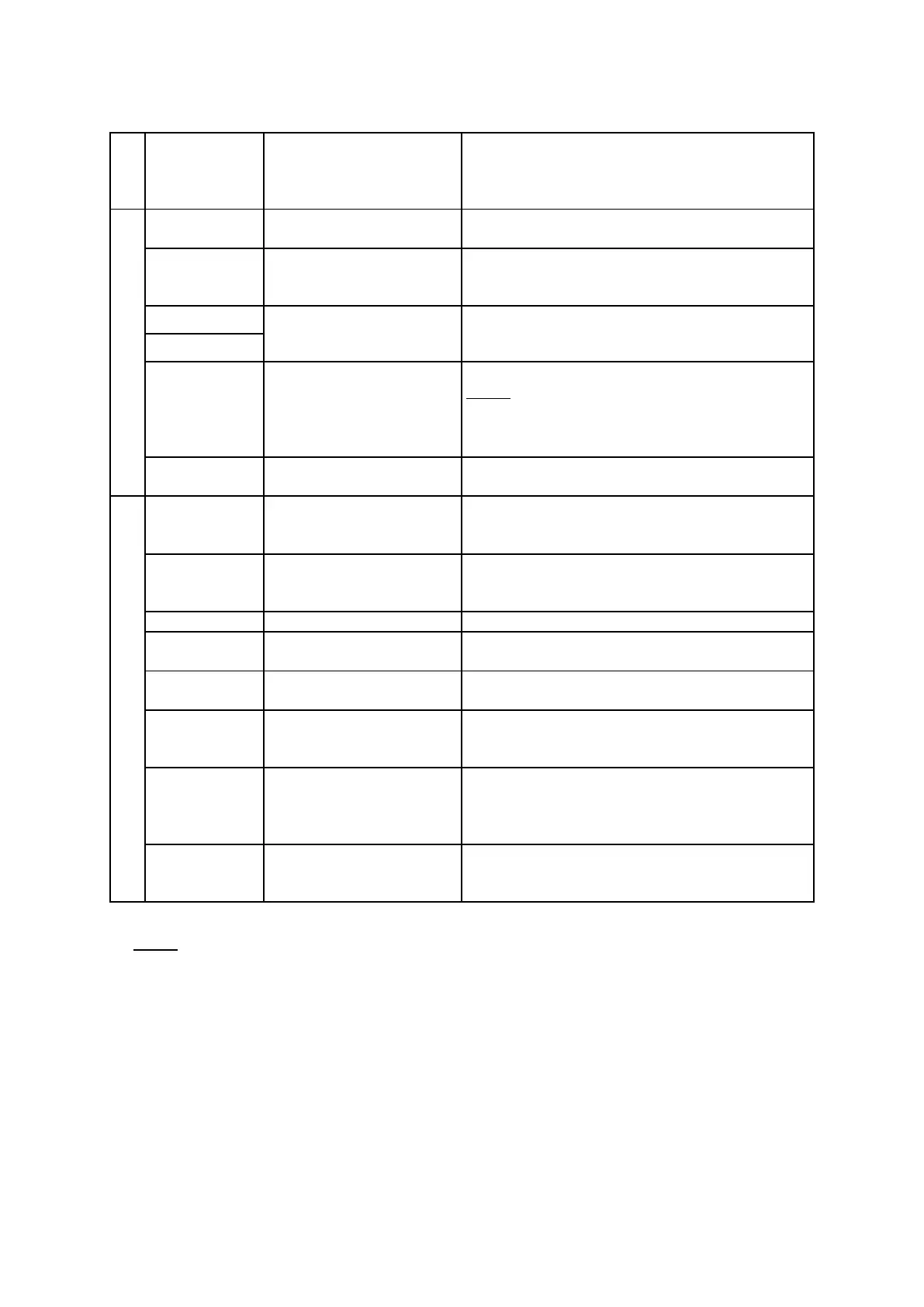

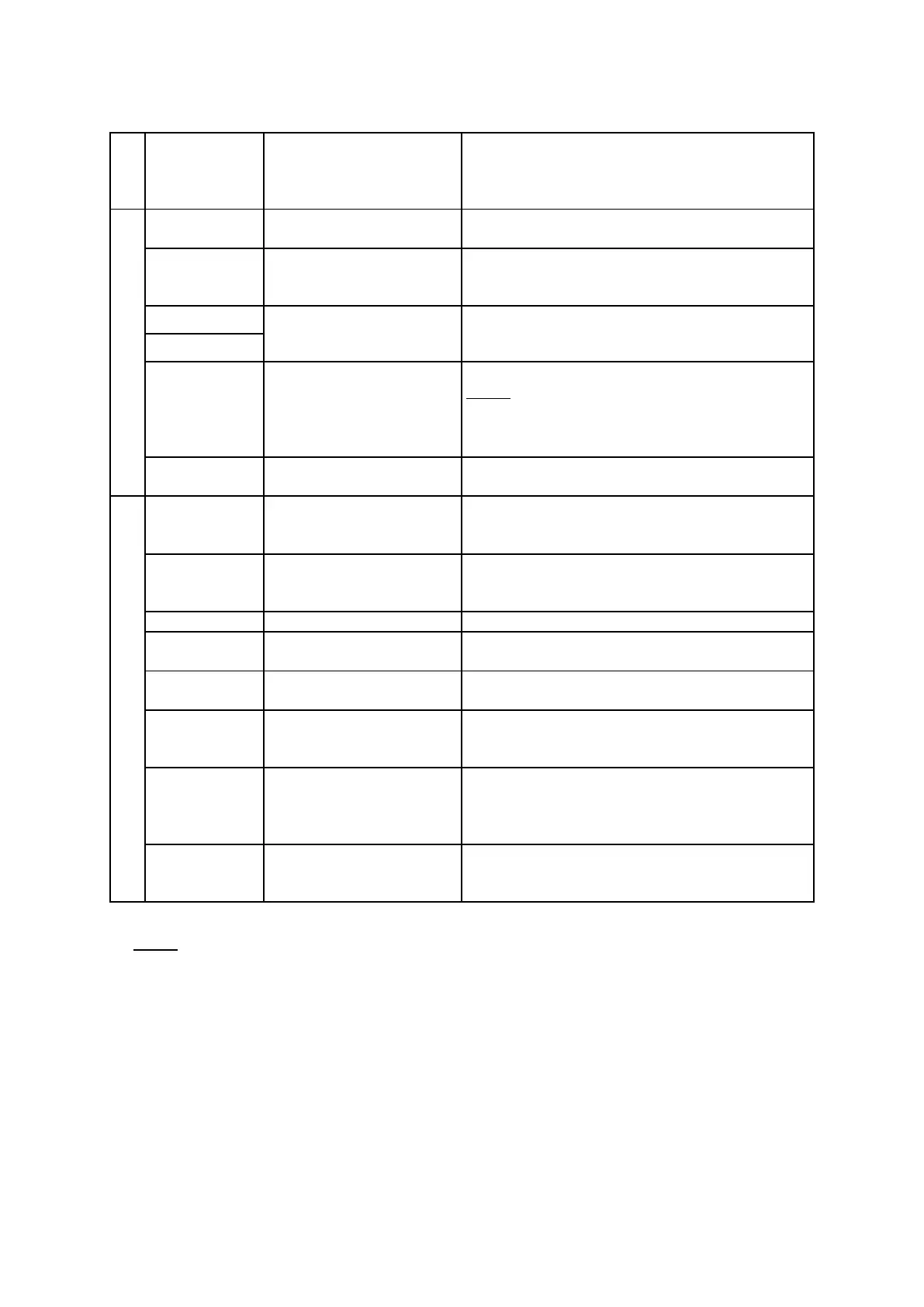

Category

Command Necessary Parameter Description

Variable, Comment, System Control

declare

Variable Type, Variable

Name

Local variable declaration

let Expression

Assign the right side sum results of the expression

to the left side variables.

The symbols +, -, *, /, =, (, ), & can be used.

rem

Character String One line comment

crem

setProgNum Program Number

Change the program number.

NOTE

Do not carry out this command while the robot is

running. Use the command callProg if you want to

change programs during a run.

setSeqNum PLC Program Number

Change the PLC program number in “system

data”.

Camera, Z Sensor

cameraWadj Work Adjustment Number

Acquire an image with the camera and calculate

the offset values

according to the [Workpiece

Adjustment] settings.

wCameraWadj

Work Adjustment Number,

Shot Number

Use this command when calculating [Workpiece

Adjustment] offset values from

Execute camera with counter adjustment

-

Increment the camera with counter adjustment

sub-counter values.

-

Clear the sub-values of the camera with counter

adjustment.

cameraTool Tool Number

Acquire an image with a camera and calculate

[TCP-X] and [TCP-Y] from

the data gained

according to [Point Tool Data Settings].

cameraPallet Pallet Routine Number

Acquire an image with the camera and set the

number of marks and coordinates acquired as the

routine number and coordinates for the

takeZWadj Work Adjustment Number

Calculate the Z offset from the data gained from

the distance/

touch sensor according to the

[Workpiece Adjustment] settings.

NOTE

For [Camera, Z Adjustment] commands, refer to the operation manual Camera & Sensor

Functions.

109

Loading...

Loading...