18z-1, 19c-1, 19c-1 EP

20

21

Please see operator manual for full details.

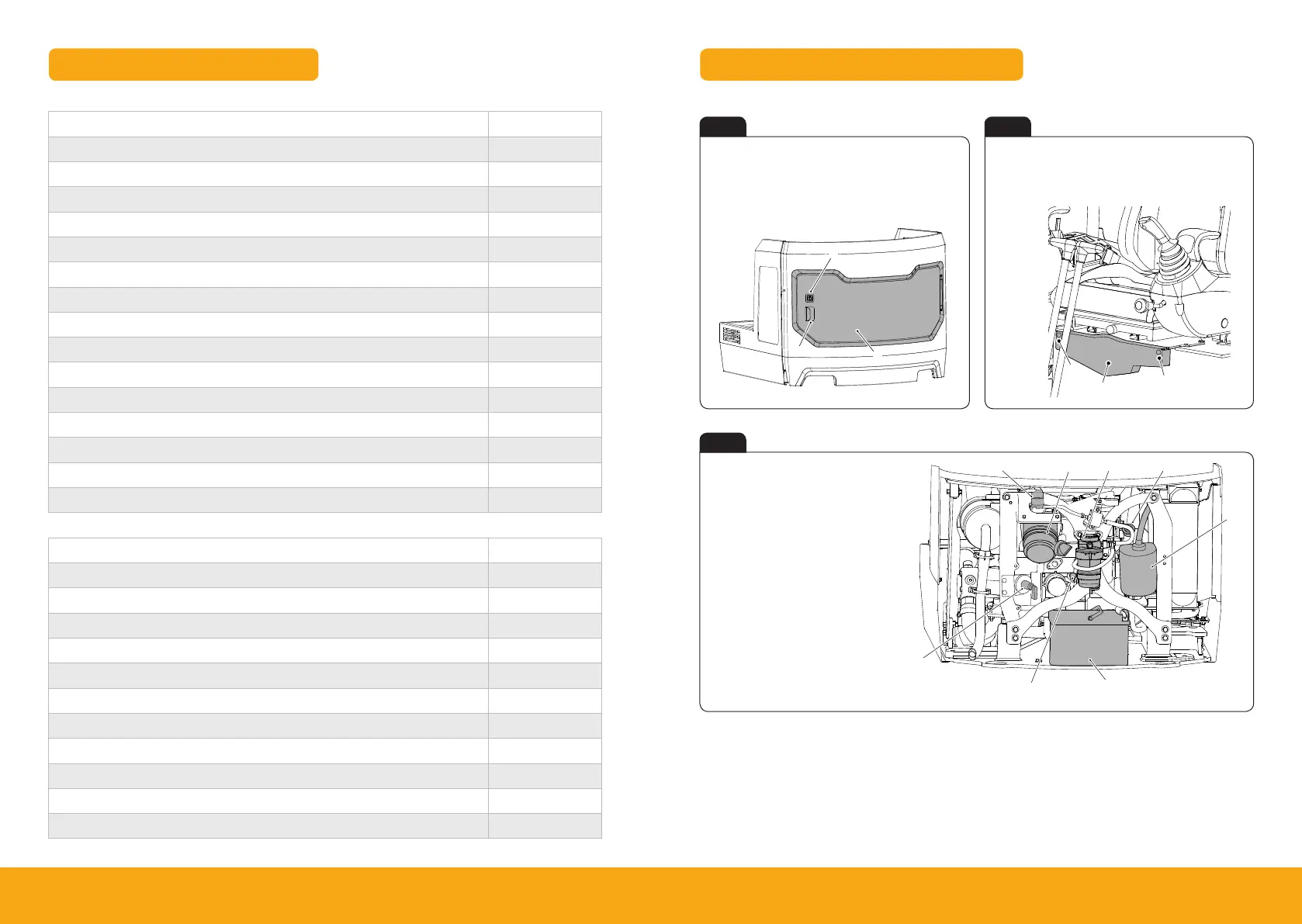

Access Covers – Service Items and Relays

Fig 24 Fig 25

A Fixings

B Relay access cover

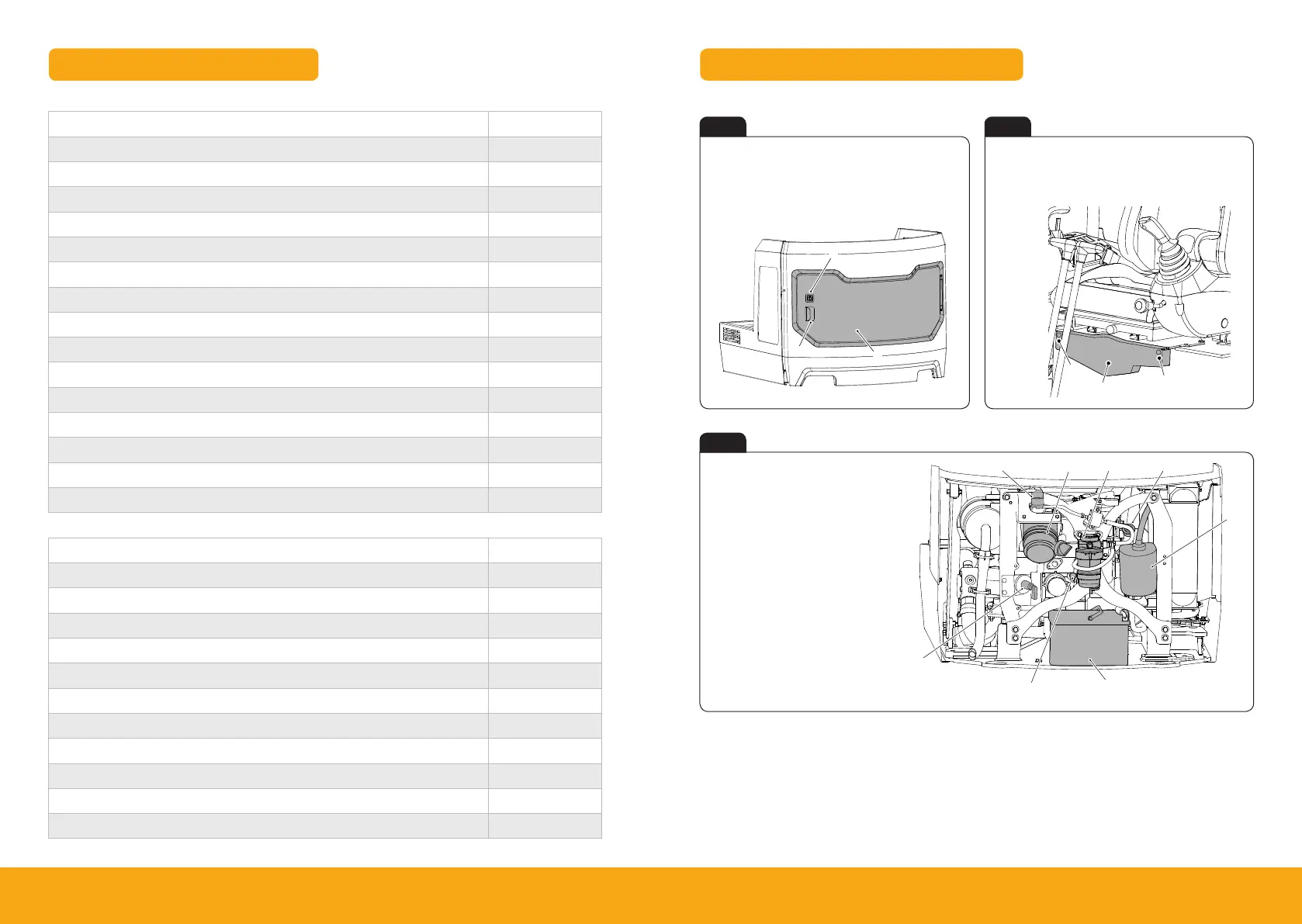

Fig 26

A Air filter

B Water separator

C Oil filler cap

D Coolant expansion bottle

E Battery

F Engine oil dipstick

G Battery isolator

H Fuel pre filter

Maintenance

Service Points

147 9831/2900-1 147

Service Points

General

The following illustrations identify the service points for the operator to perform the daily and weekly

maintenance tasks.

Engine Compartment

Figure 112.

E

G

D

A Air filter B Water separator

C Oil filler cap D Coolant expansion bottle

E Battery F Engine oil dipstick

G Battery isolator H Fuel pre filter

A Lock

B Engine compartment cover

C Handle

Maintenance

Access Apertures

149 9831/2900-1 149

Access Apertures

General

When moved to their maintenance position, the access panels give you access to parts or areas of the machine

that are not required during machine operation.

Before you operate the machine, make sure that all of the access panels are correctly in their closed or installed

positions.

Engine Compartment Cover

Open

WARNING The engine has exposed rotating parts. Switch off the engine before working in the engine

compartment. Do not use the machine with the engine cover open.

WARNING Airborne particles of light combustible material such as straw, grass, wood shavings, etc. must

not be allowed to accumulate within the engine compartment or in the propshaft guards (when installed).

Examine these areas frequently and clean at the beginning of each work shift or more often if required.

Before opening the engine cover, make sure that the top is clear of debris.

1. Make the machine safe with the excavator arm lowered.

2. Use the ignition key to unlock the cover.

3. To release the latch, pull the handle.

Figure 114.

B

C

A

A Lock B Engine compartment cover

C Handle

Maintenance

Electrical System

182 9831/2900-1 182

Figure 133.

A

A

B

A Knob B Cover

Relays

Replace

Refer to: Relays.

1. Make the machine safe.

Refer to: Maintenance Position (Excavator Arm Lowered).

2. There are relays behind a panel under the seat. Refer to Figure 134.

2.1. Loosen the knob.

2.2. Open the cover to get access to the relays.

Service/Maintenance

Daily Checks (10h) Check

Check engine for leaks and oil level Visual check

Check engine coolant for leaks, contamination and level Visual check

Check condition of cooling pack and system Visual check

Check hydraulic oil level Visual check

Check the condition of welded structure Visual check

Check window washer fluid level Visual check

Check condition of bodywork and framework Visual check

Check condition of attachments / optional equipment Visual check

Grease attachments / optional equipment as required Lubricate

Check for excessive exhaust smoke Visual check

Check fuel system for leaks & contamination Visual check

Check operation of all services i.e. excavator, dozer etc. Operate

Check operation of all electrical equipment i.e horn, alarms etc. Operate

Check the track and running gear operation Operate

Check operation of the hour meter Viual check

Weekly Checks (50h) Check

Clean cooling pack Clean

Drain water from water separator on fuel filter Clean

Check condition of drive belt Visual check

Check hydraulic hoses / pipework for leaks and damage Visual check

Check condition of the rams Visual check

Check the condition of the electrical wiring Visual check

Clean the battery terminals Clean

Check condition and tension of tracks Visual check

Check presence of all pivot pin retaining bolts Visual check

Grease slew ring bearing Lubricate

Grease window and door hinges Lubricate

Loading...

Loading...