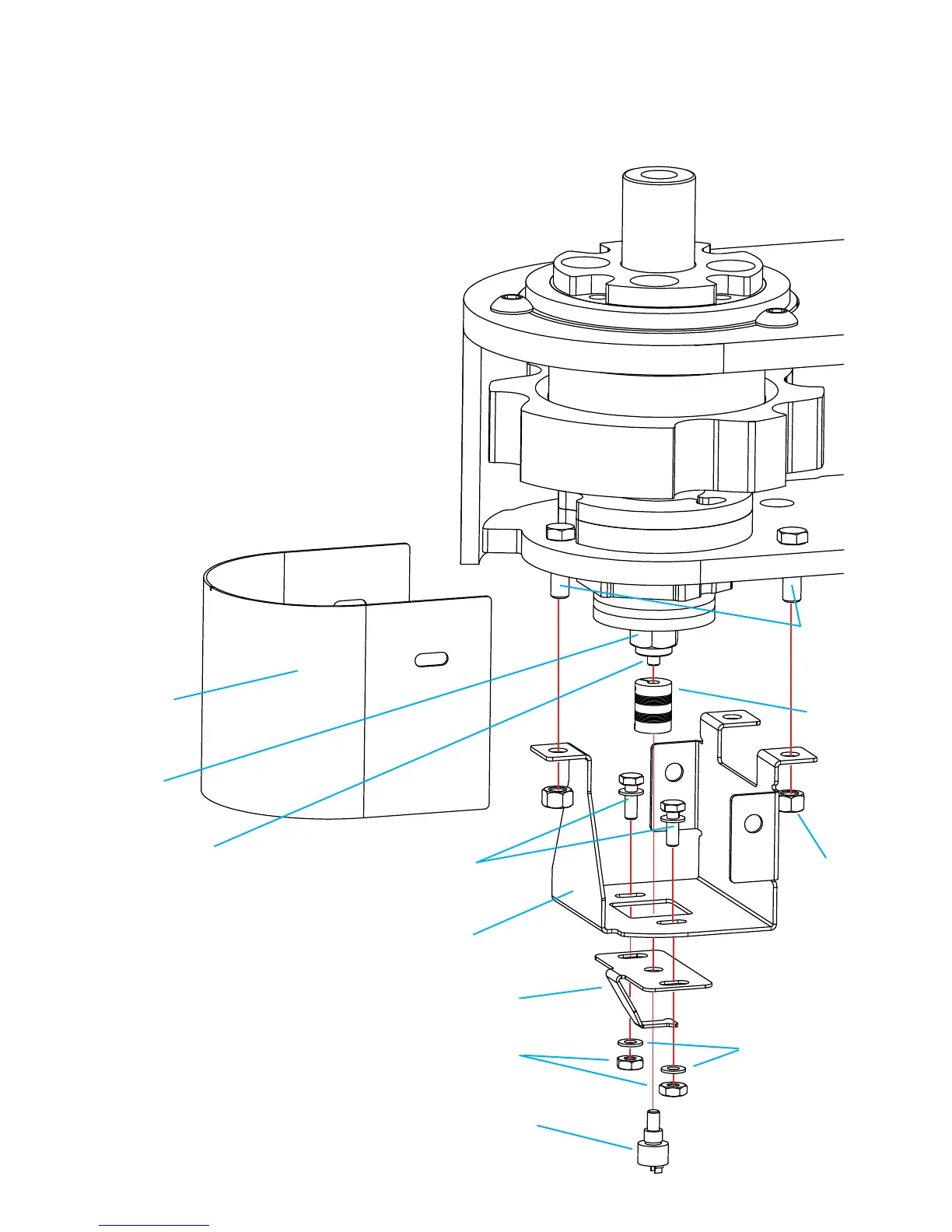

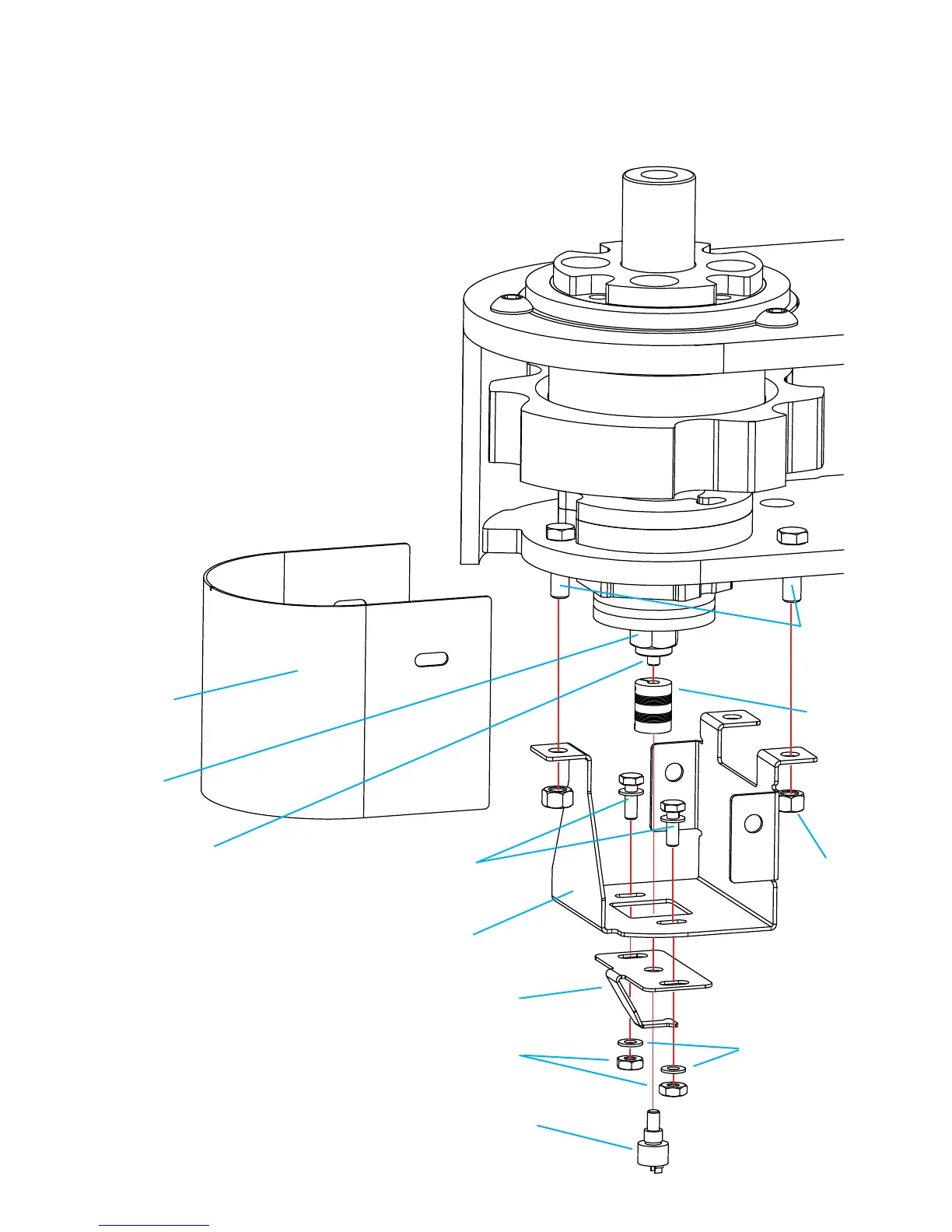

Installing the Encoder

1) Install the encoder mount.

2) Install the encoder onto the encoder bracket

and tighten. Do not place it into the machine.

3) Slide the encoder into the coupling

approximately .225” and tighten. Be careful not

to strip the small bolt.

NOTE: The shaft must not protrude into the

slotted section of the coupler or it will not be

able to ex properly.

4) Position this assembly into the bender as

shown. Do not tighten the 1/4” bolts. Adjust the

encoder threaded rod up or down so that when

tighten, the encoder’s shaft only extends into it

approximately .225” also.

5) Securely tighten the encoder stud’s 3/4” nut.

6) Tighten the 1/4” bracket bolts being careful not

to force the coupler out of alignment.

7) Tighten the coupler’s upper socket head bolt.

8) Rotate the spindle by hand and verify coupler

does not show signs of excessive misalignment.

Max run out is .020” total over 360

o

.

1/4” hex nuts

1/4” washers

1/4”-20 x 3/4” bolt

& 1/4” washers

Absolute position encoder

(Installed with a thin nut that is

not shown)

Encoder

coupling

Encoder bracket

3/8” x 1”

bolts (3x)

3/8” hex nuts

(3x)

Encoder guard

Encoder mount

Encoder stud

3/4” hex nut

Encoder components

Page 16

Loading...

Loading...