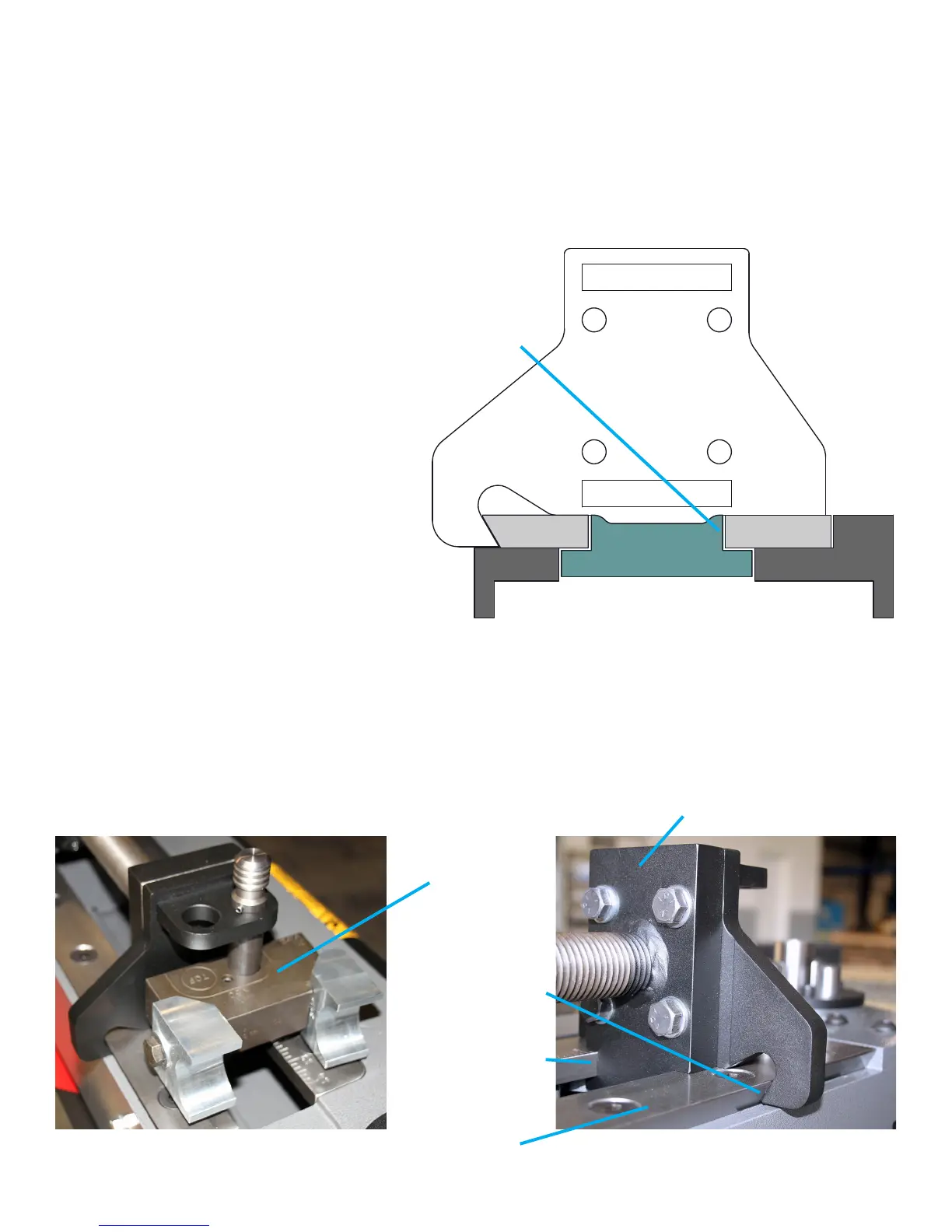

The Model 54 has been designed to allow new tooling to be easily added in the future. This is accomplished

by using a tool plate that bolts to the pressure screw block. Various tool plate’s are available depending upon

the application. The majority of die sets use the standard 2 hole tool plate that is included with the bender. This

plate accommodates dies for up to 2.5” tube and 2” pipe. However, a die set such as 3” o.d. tube may require

a different tool plate. The correct tool plate for a particular die set can usually be determined by examining the

tooling and looking for the engraved markings such as shown below.

The dovetailed tool plate design was added

to the Model 54 in April of 2014. Therefore, if

the bender was purchased before that date it

may not have the upgrade installed. If this is

the case, please call our sales deptartment.

We feel this is a signicant improvement to

the bender and therefore offer this as a FREE

upgrade.

When the bender is under load, the dovetail

in the tool plate will suck down onto the outer

rail’s dovetail and lay at. This ensures the

tool plate’s pin holes are vertical and are not

tilted. It is CRITICAL that the tool plate and

the outer rail’s dovetailed surfaces are in full

contact under load.

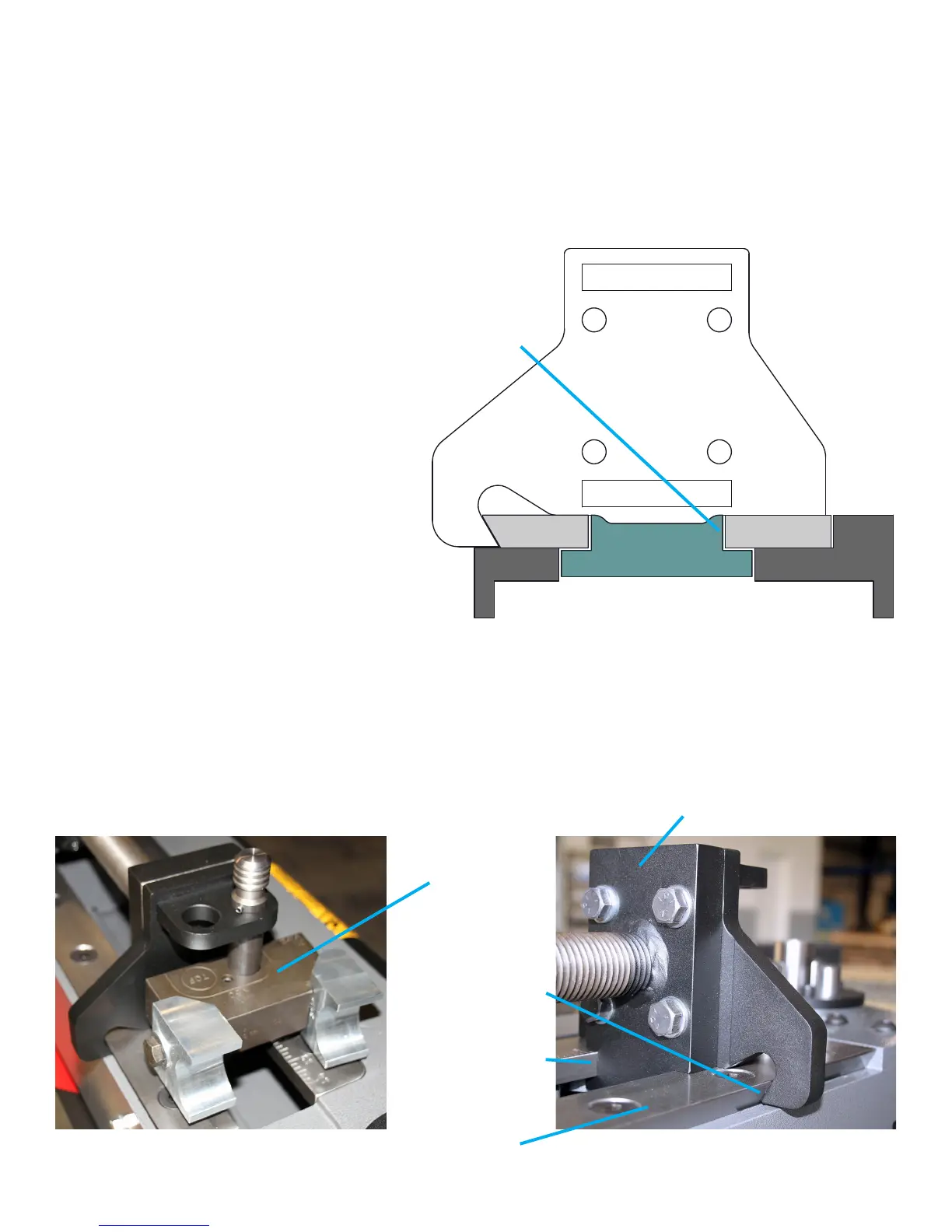

To verify this, use the following procedure.

Without any tooling in the bender, push the

tool plate to the left towards the cylinder and try to raise the right side nearest the outer rail. If it does not tilt

towards the cylinder or try to lift then everything is ne. If this is not the case, there is not enough clearance

between the inner rail and the pressure screw block’s left side slot. This should only happen when a older bender

is being upgraded. To remedy this you can remove the pressure screw and using the edge of a le, remove

material from the bottom of the left slot until a clearance of .010” or slightly more is obtained. This can be seen

in the lower right photo. The amount of material to remove is usually only about .020-.030”. If you wish you may

also send the pressure screw to the factory and we will be happy to mill the slot deeper for free.

Tool plate

Outer rail Inner rail

Pressure screw block

Tool plate’s rear viewTwo hole tool plate’s front view

Outer rail

Tool plate’s dovetail

must fully contact

the rail.

e engraving on the

tooling shows which

adapter to use.

Tool Plate Installation

If necessary

le here

when

upgrading

bender

Pressure screw block

Page 8

Must have .010” or

more clearance here

under load.

Loading...

Loading...