46 - Maintenance

PROPELLER

IMPORTANT: Apply

Triple-Guard

grease to the en-

tire propeller shaft before installing the propeller. At

least annually, remove the propeller and check for

debris. Clean the shaft and regrease it before rein-

stalling a propeller.

Installation

Slide thrust washer onto shaft with shoulder facing

aft.

Slide propeller onto shaft, engaging the splines and

seating it on the thrust washer.

Slide spacer onto the shaft and engage the propel-

ler shaft splines.

Slide washer onto propeller shaft.

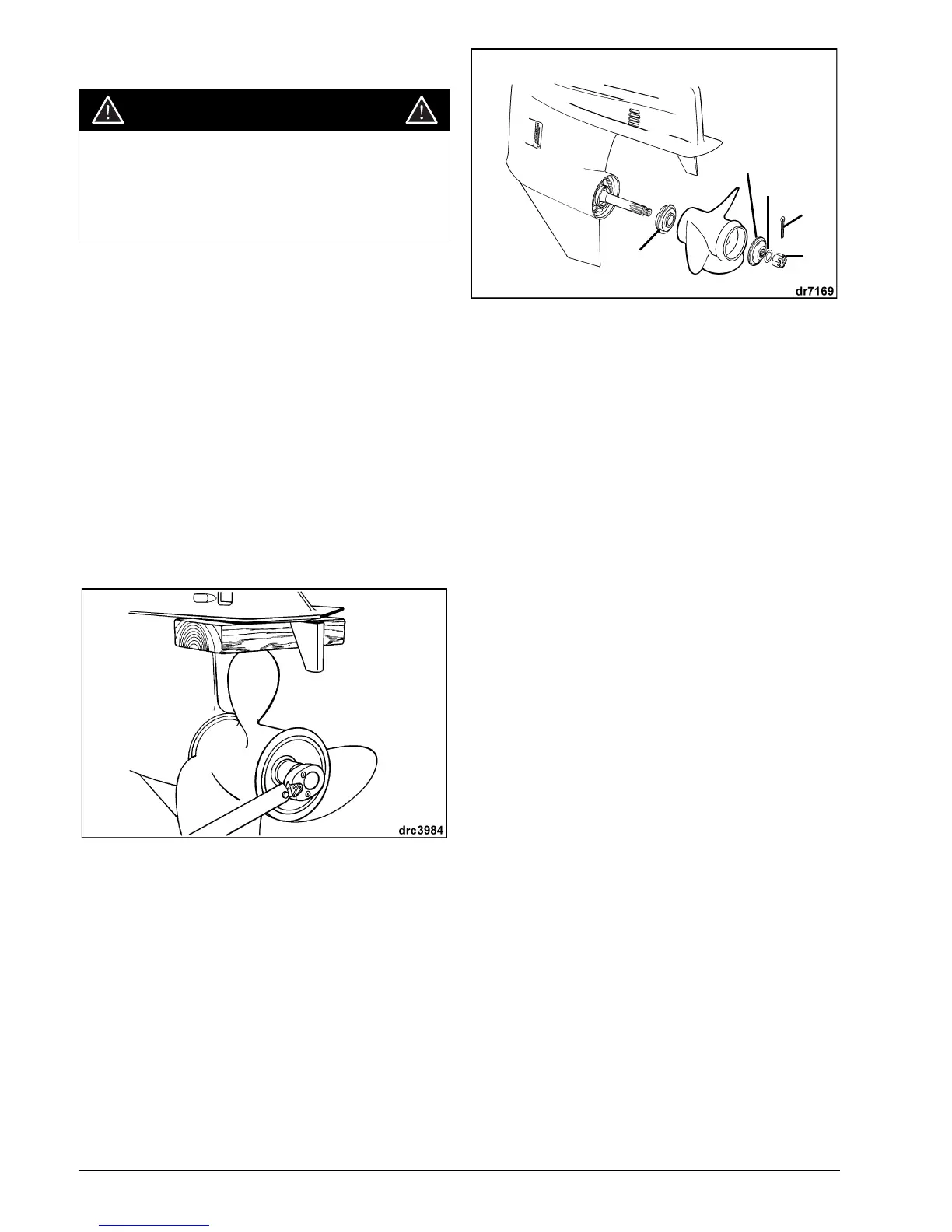

Wedge a block of wood between the propeller

blade and the anti-ventilation plate.

Install propeller nut and tighten to a torque of 36 to

43 ft.lbs. (50 to 60 N·m).

Continue to tighten propeller nut until nut slots and

cotter pin hole are aligned. Install new cotter pin

and bend ends to secure.

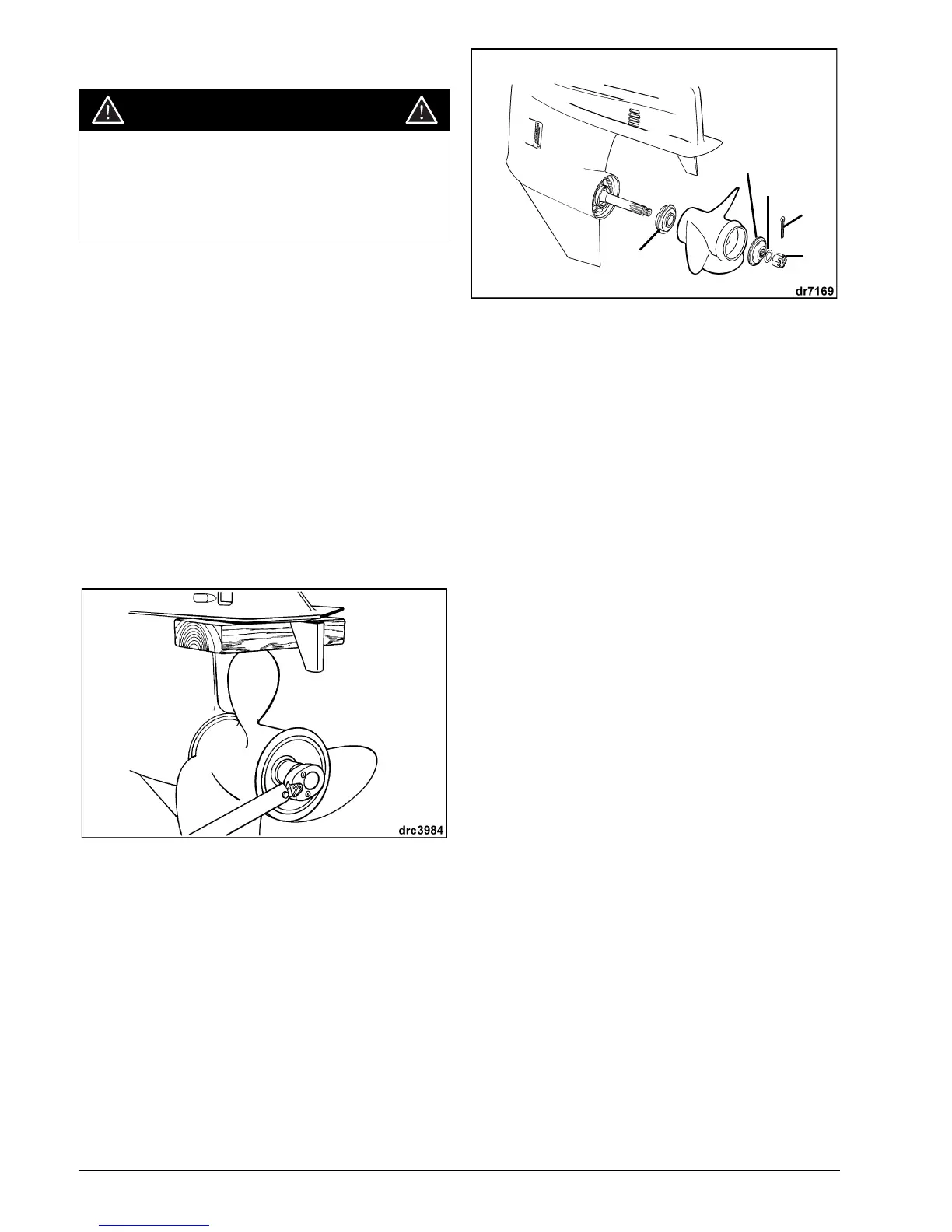

1. Thrust bushing

2. Spacer

3. Washer

4. Cotter pin

5. Propeller nut

Remove block of wood. Make sure engine is in

NEUTRAL; give propeller a spin. It must turn freely.

Repair

If your propeller hits a solid object, the impact is par-

tially absorbed by the rubber bushing in the hub to

help prevent damage to the engine. A strong impact

can damage the hub and propeller blades. Damage

to blades can cause unusual and excessive vibra-

tion. Damage to the hub can cause excessive en-

gine RPM with little forward movement.

IMPORTANT: Avoid or limit operation using a dam-

aged propeller. Carry a spare propeller.

Keep your propeller in good condition. Use a file to

smooth slight damage to blade edges. See your

Dealer for repair of serious damage.

WARNING

When servicing the propeller, always shift

the outboard to NEUTRAL position, turn the

key switch OFF and disconnect battery pos-

itive (+) cable so the engine cannot be

started accidentally.

1

2

3

4

5

Loading...

Loading...