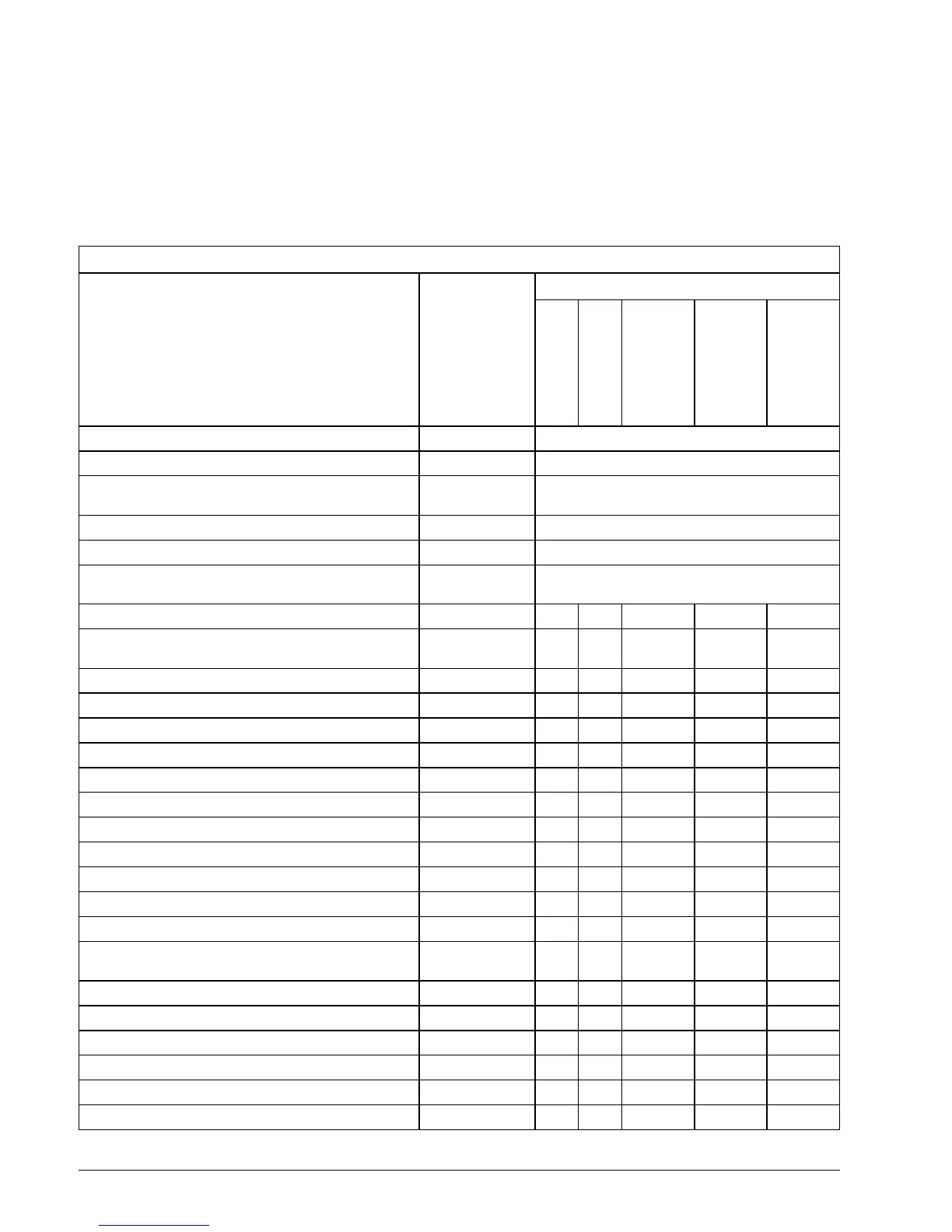

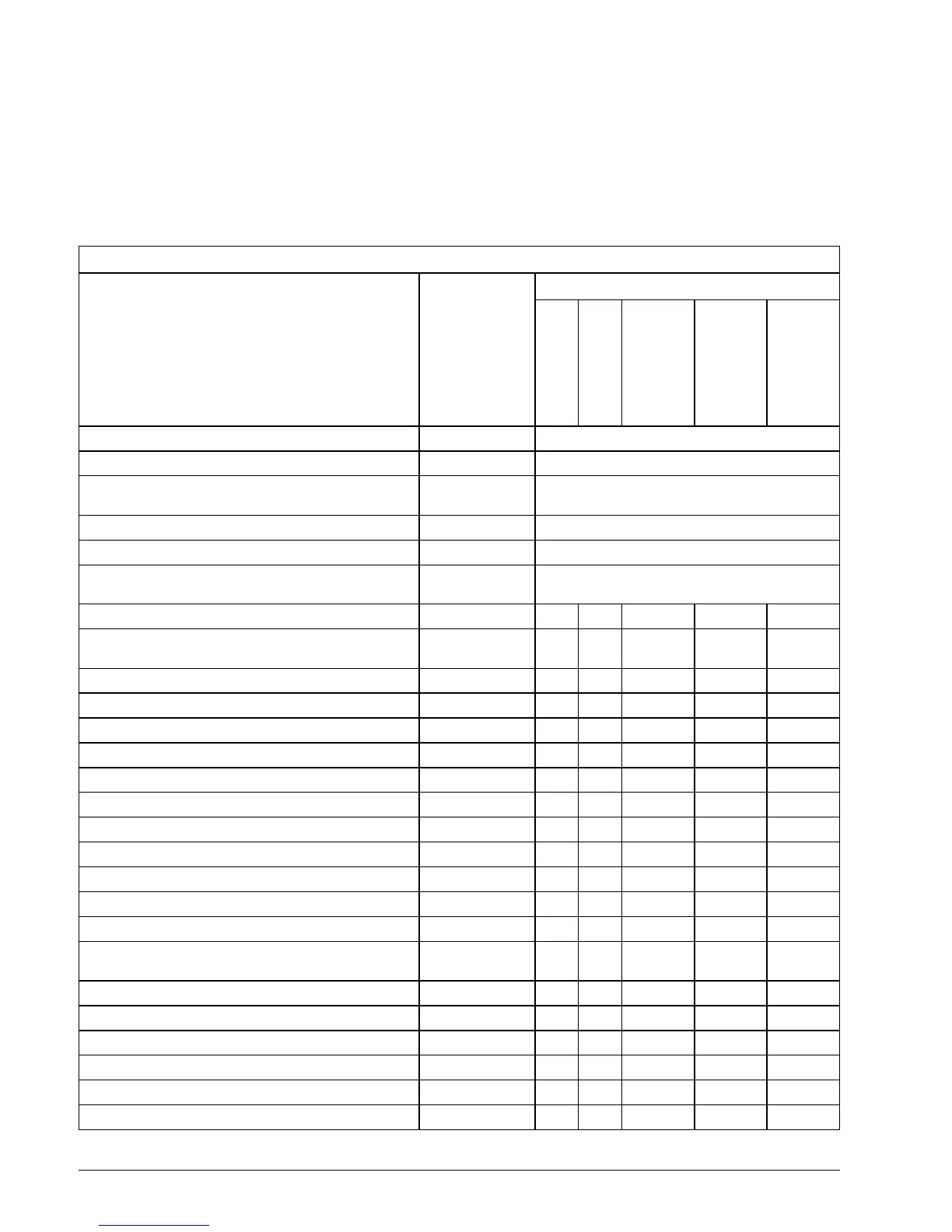

50 - Maintenance

ENGINE MAINTENANCE AND INSPECTION SCHEDULE

Routine maintenance is necessary for all mechanized products. Periodic maintenance contributes to the

product’s life span. The following maintenance chart provides guidelines for engine maintenance and in-

spection scheduled to be performed by you and/or by an authorized Dealer. The schedule should be ad-

justed according to operating conditions and use.

The recommended lubricants have been formulated to protect bearings, gears and engine components.

They must be used to avoid damage caused by improper lubrication.

IMPORTANT: Schedules for rental operations, commercial applications or high hour use will require

greater frequency of inspection and maintenance.

Engine Maintenance and Inspection Schedule

Description

Engine Care

Product

Frequency

Each Use

10-Hour

Inspection

Every 50 Hours

or 6 months

Every 100 Hours

or Annually

Every 200 Hours

or Biannually

Mechanical steering, lubricate

(1)

7 Every 60 days / Every 30 in Saltwater

Tilt tube, inspect and lubricate

(1)

7 Every 60 days / Every 30 in Saltwater

Swivel bracket / tilt support bracket, inspect and

lubricate

(1)

7 Every 60 days / Every 30 in Saltwater

Throttle and shift linkage, inspect and lubricate

(1)

7 Every 60 days / Every 30 in Saltwater

Remote control cables, lubricate

(1)

7 Every 60 days / Every 30 in Saltwater

Lubrication and corrosion protection for metallic

components

4 Every 60 days / Every 30 in Saltwater

Battery connections and condition, verify 7 O D

SystemCheck

self-test and warning horn, verify

operation

OD

Anticorrosion anodes, verify operation O D

Water intake screens, verify condition O D

Overboard water pump indicator, verify operation O D

Steering system check, verify function O D

Throttle and shift operation, verify function O D

Emergency stop circuit and lanyard, verify function O D

Flush cooling system O

Operator’s Guide, onboard O

Crankcase oil level, check O D

Engine upper and lower motor covers, clean and wax O

Operator’s Guide, review O

Fuel and oil system components, inspect and repair

leaks

(2)

DD

Fastener inspection, tighten loosened components D D

Thermostat, inspect and verify operation

(2)

DD

Power tilt/trim fluid, inspect fluid level 6 D D

Engine to transom mounting hardware, re-torque D D

Electrical and ignition wires and connections, inspect D D

Gearcase lubricant replace 5 D D

Loading...

Loading...