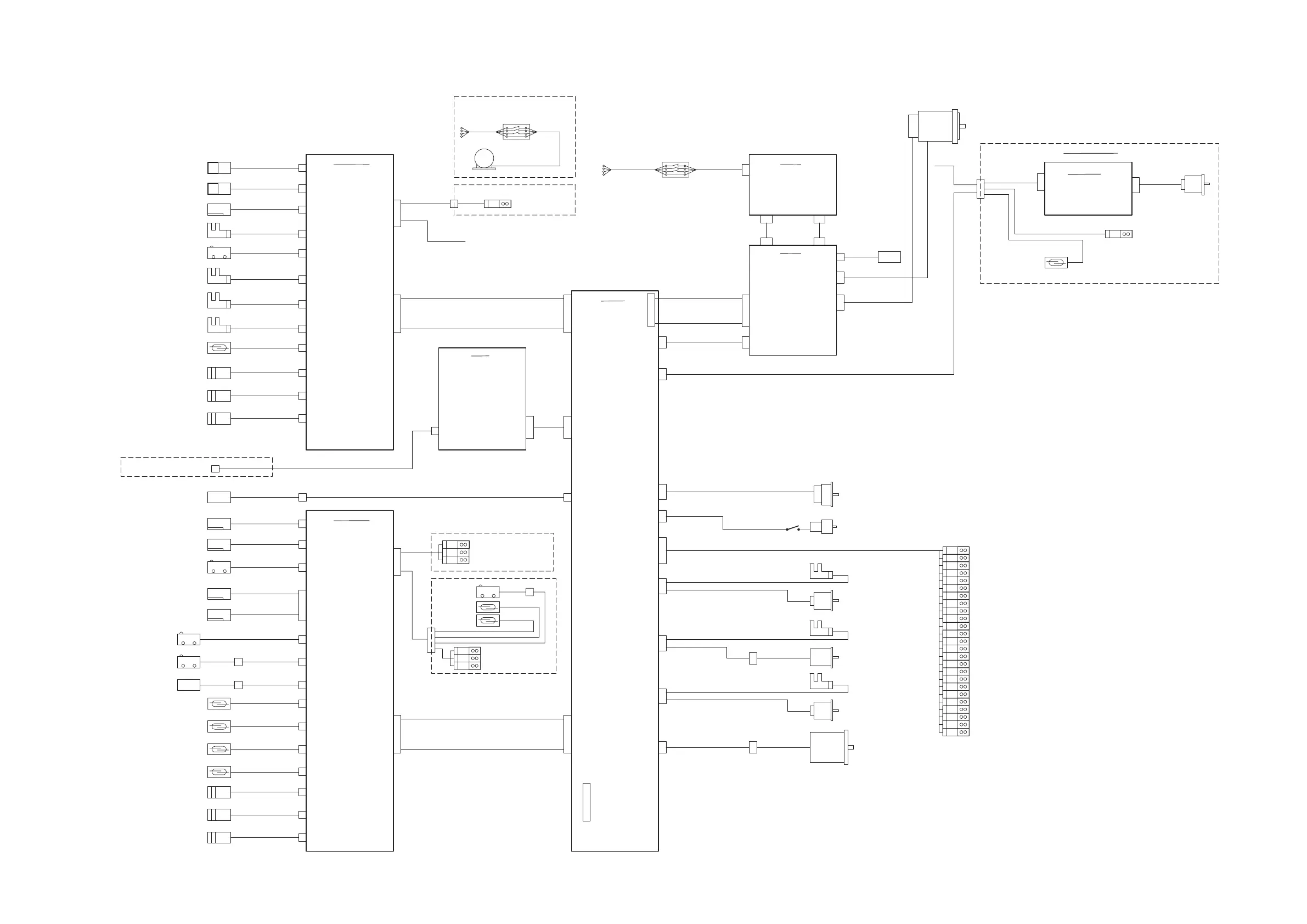

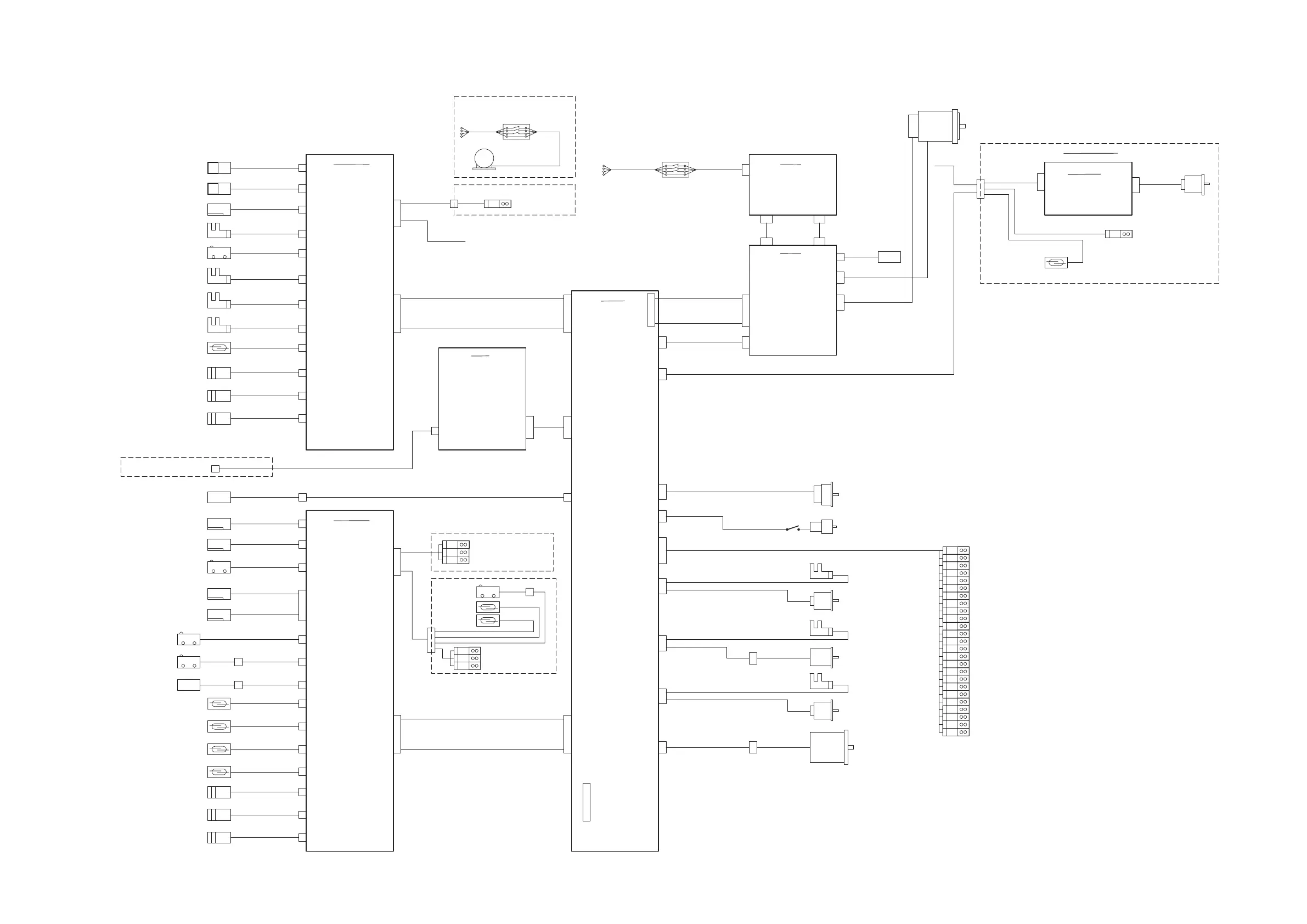

12. Circuit diagrams

(1) Block diagram

– 203 –

Photo sensor for clamp foot origin detection

Photo sensor for

binder upper detection

CN71A

CN171

40043989

CN62A

40043997

Proximity sensor for needle thread trimming

detection (left)

CN63A

40043996

Proximity sensor for needle thread trimming

detection (right)

Reflex optical sensor for stacker material detection

CN65A

4004400

2

Photo sensor for clamp foot step-out detection

CN

66A

CN166

40043982

Micro switch for binder opening detection

CN68A

4004400

1

Photo sensor for mar

king light

2nd origin

CN77A

CN177

40043983

CN75

A

CN17

5

4004398

6

CN79

A

40044626

Cylinder sensor for center

knife rise detection

CN

85B

HE000530000

Optional laser marking light

CN

8

5B

HE0005

20000

4

3

3

3

3

4

4

2

2

2

2

3

3

3

3

CN83A

40043987

40032964 #3

2

0

INT PCB [A]

2

CN138

2

50

CN60

B

40043999

Reflex optical sensor (left) for flap material end

detection

CN

6

1B

40044000

Reflex optical sensor (right) for flap material end

detection

Micro sw

itch for corner knife drawer detection

CN62B

40043991

CN79

B

40044627

Cylinder sensor for lower detection of mov

ing-side

corner knife

Cy

linder sensor for upper detection of moving

-side

corner

knife

Vertical reference laser mar

king light

Horizontal reference laser marking light

Cylinder sensor for

u

pper detection of fix

ed-side

corner knife

Cy

linder sensor for lo

w

er detection of fixed-side

corner

knife

CN85A

HE000520000 #3

HE000530000 #3

Optional laser mark

ing light

Optional laser marking light

Optional laser mark

ing light

A

ir presser detecting switch

CN85

A

3

3

3

2

2

2

CN83B

2

0

INT PCB

[B]

CN64B

40043995

6

Reflex optical sensor

(

left

) for bobbin

thread remaining amo

unt detection

Reflex optical sensor (right

) for bobbin

thread remaining amo

unt detection

Lap start switch

CN65B

40026945

4

Pa

u

se

SW

CN69B

40043994

2

2

32002354

Pedal hole pot sensor

CN75B

40043984

3

4

40006136

CN96B

CN275B

CN

8

5A

2

CN80B

40044628

2

CN81

B

4004462

9

2

CN82

B

40044630

2

50

50

50

MAIN P

CB

S

olenoid v

alve for interlining draw

-

o

ut

2

S

olenoid

v

alve for interlining feed

2

S

olenoid val

ve for interlining cutter

2

1

4

CN283

S

tack

er unit opening

Detecting mocro switc

2

CN11

5

Material wiper origin

A

ir cylinder sensor

A

ir c

ylinder sensor

C

lamp origin

2

Solenoid

v

al

ve for CB stacker material wiper

2

Solenoid valve for C

B stac

ker material

presser

2

Solenoid valve for C

B stac

ker material

clamp

6

CN1

FLT PCB

5

3

5

3

CN

3

CN

2

CN17

CN13

SDC PCB

2

4

9

CN10

CN16

CN1

4

Main shaft servo motor of the sewing machine

Fan motor

34

34

8

14

CN84A

CN29

CN

39

CN15

CN11

CN31

5

CN

48

5

CN148

Clamp foot pulse motoor

P

ulse motor for corner knife opening

6

Photo sensor for

back-tack motor, origin

Pluse motor for back-tack

needle

throwing

CN338

3

CN238

40043993

40043990

CN

38

7

Photo sensor for corner knife opening, origin

CN202

3

40043975

CN37

8

4

CN

2

01

Pulse motor for marking light mov

ement

6

Photo sensor for marking light motor

, origin

CN204

3

CN203

40043979

CN36

7

5

0

CN45

S

olenoid valve for center

knife elevator

2

2

Solenoid v

al

ve for bobb

in thread trimmer

Solenoid valve for needle thread trimmer

2

S

olenoid valve for thread release

2

Solenoid valve for thread tension disk

floating

2

Solenoid valv

e for sensor air blow

of

bobbin thread remaining detection

2

S

olenoid valve for OP interlining

presser rise

2

Solenoid valve for OP darts extension elevator

2

Solenoid v

al

v

e for binder jump feed rise

2

Double solenoid valve for

b

inder rise

2

VL1

VL

2

VL3

VL4

VL

5

VL6

VL7

VL

8

VL9

VL10

Doub

le solenoid val

v

e for binder fall

2

Solenoid v

al

v

e for corner

k

nife elevator

2

S

olenoid valve for

O

P moving

-

side corner

knife elevator

2

Left solenoid valve for mov

ing-side garment body clamp

2

Left-returning solenoid valve for moving

-side garment body clamp

2

Right solenoid valve for moving-side garment body

clamp

2

R

ight

-returning solenoid valve for mov

ing-side garment body clamp

2

Left solenoid valve for flap presser

2

Right solenoid valve for flap presser

2

Left solenoid valve for folding plate

2

VL

11

VL1

2

VL13

V

L14

VL1

5

VL16

VL

17

VL

18

VL19

VL

20

Right solenoid v

al

ve for folding plate

2

Left double solenoid v

al

ve for clamp foot rise

2

Left doub

le solenoid valve for clamp foot fall

2

Right double solenoid valve for clamp foot rise

2

Right double solenoid valve for clamp foot fall

#1 : Single phase 200 to 240V specification (Europe, Genelal export)

#2 : 3-phase 200 to 240V specification (Japan, JUS)

#3 : Optional equipment

2

VL2

1

VL22

VL

23

VL2

4

VL25

CN54

26

CN101

CN

34

Co

unter SW for production control

CN105

2

CN105

2

IP-310

J

7

8

G

56042540A0

4

CN

30

3

40008168 #3

26

2

DC motor for lower bobbin winder

34

CN35

CN32

CN84B

12

CN49

14

CN284

Optional roller stacker

PMDC X1 PCB

12

CN1

Pulse motor for marking

light movement

6

CN321

CN2

8

Solenoid valve for roller

stacker ele

vator

2

Roller stack

er rise detection

Cylinder sensor

CN

4

7

9

Center knife rotation brushless motor

11

CN205

40025260

40025260

4004489

6

400

2

5270

40032977

40000046 #1

40000056 #2

400005401

40043974 #1

40032971 #2

40058397 #1

40058398 #2

40005726

40005393

40005394

40030983

40043980

4003

2963

40035098

40044887 #3

40032964 #3

40044632 #3

40044888 #3

40044887

40040396 #3

400439

7

8

400439

77

RSTSIG(4A)

RSTSIG(2A)

40032964 #3

40032

964 #3

40044631 #3

40044

631 #3

40044893 #3

40043985

CN

8

5B

2

HE

000

5

20000 #3

HE

000

5

30000 #3

Vacuum unit

Vacuum release valve

solenoid

HA003980000 #3

40044892 #3

G6951172CA0 #3

Loading...

Loading...