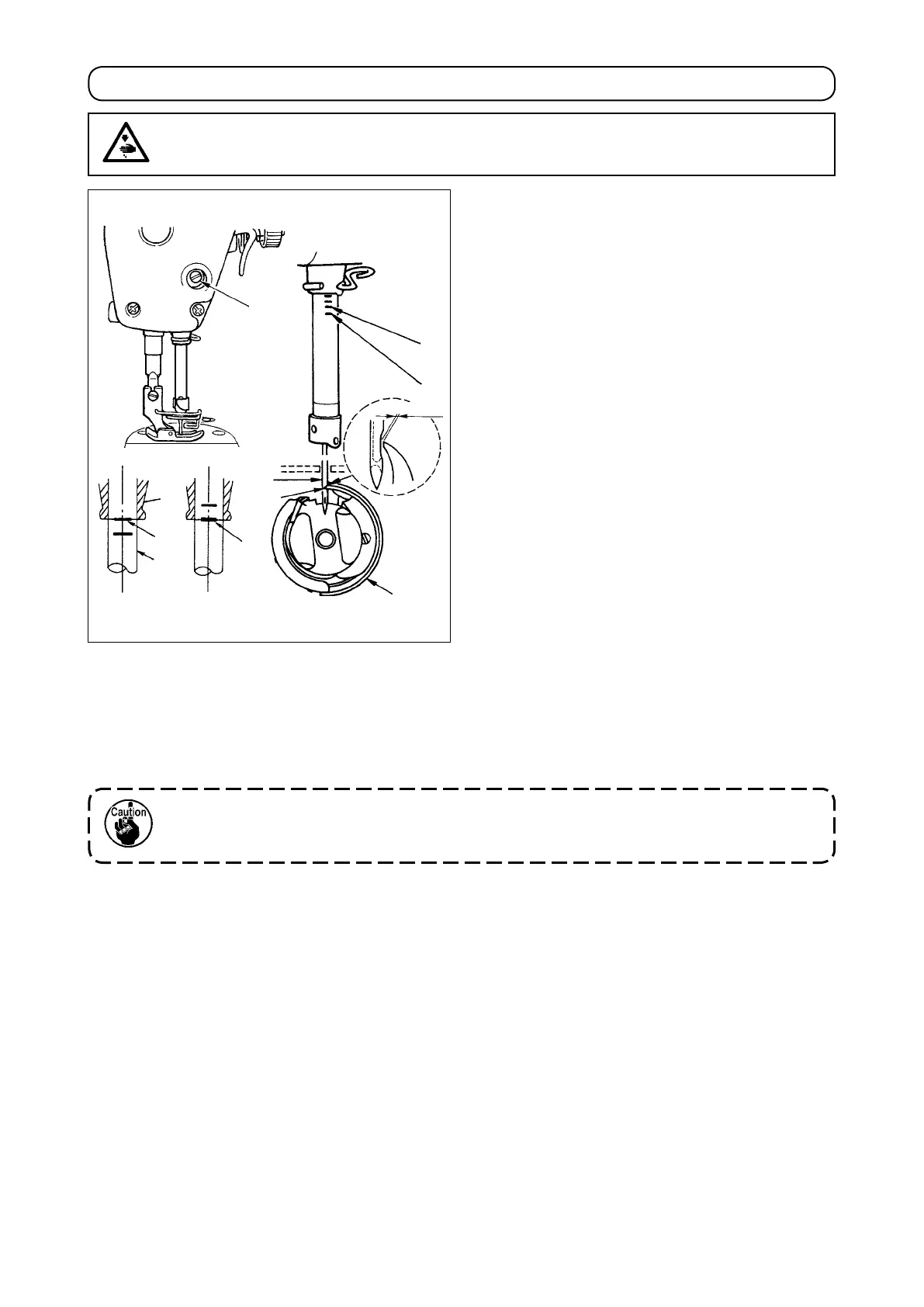

18. NEEDLE-TO-HOOK RELATIONSHIP

(1) Adjust the timing between the needle

and the hook as follows :

1) Turn the handwheel to bright the needle bar down

to the lowest point of its stroke, and loosen set-

screw

1

.

(Adjusting the needle bar height)

2) This machine uses the DB needle. To use the DB

needle, align engraved marker line

A

of needle

bar

2

with the lower end of needle bar lower

bushing

3

and tighten needle bar connecting

stud setscrew

1

.

(Adjusting position of the hook

a

)

3) This machine uses the DB needle. To use the

DB needle, loosen two hook setscrews, turn the

handwheel to move needle bar

2

upward its

engraved marker line

B

is aligned with the lower

end of needle bar lower bushing

3

.

4) After making the adjustments mentioned in the

above steps, align hook blade point

5

with

the center of needle

4

. Provide a clearance of

0.04 mm to 0.1 mm (0.06 to 0.12 mm for DDL-

8100eH) (reference value) between the needle

and the hook, then securely tighten setscrews in

the hook.

0.04 to 0.1 mm

1

2

3

4

5

A

B

a

A

B

WARNING :

To avoid possible personal injury due to abrupt start of the machine, turn off the power to the

machine and check to be sure that the motor has totally stopped rotating in prior.

If the clearance between the blade point of hook and the needle is smaller than the specied

value, the blade point of hook will be damaged. If the clearance is larger, stitch skipping will

result.

Loading...

Loading...