– 1 –

1. SPECIFICATIONS

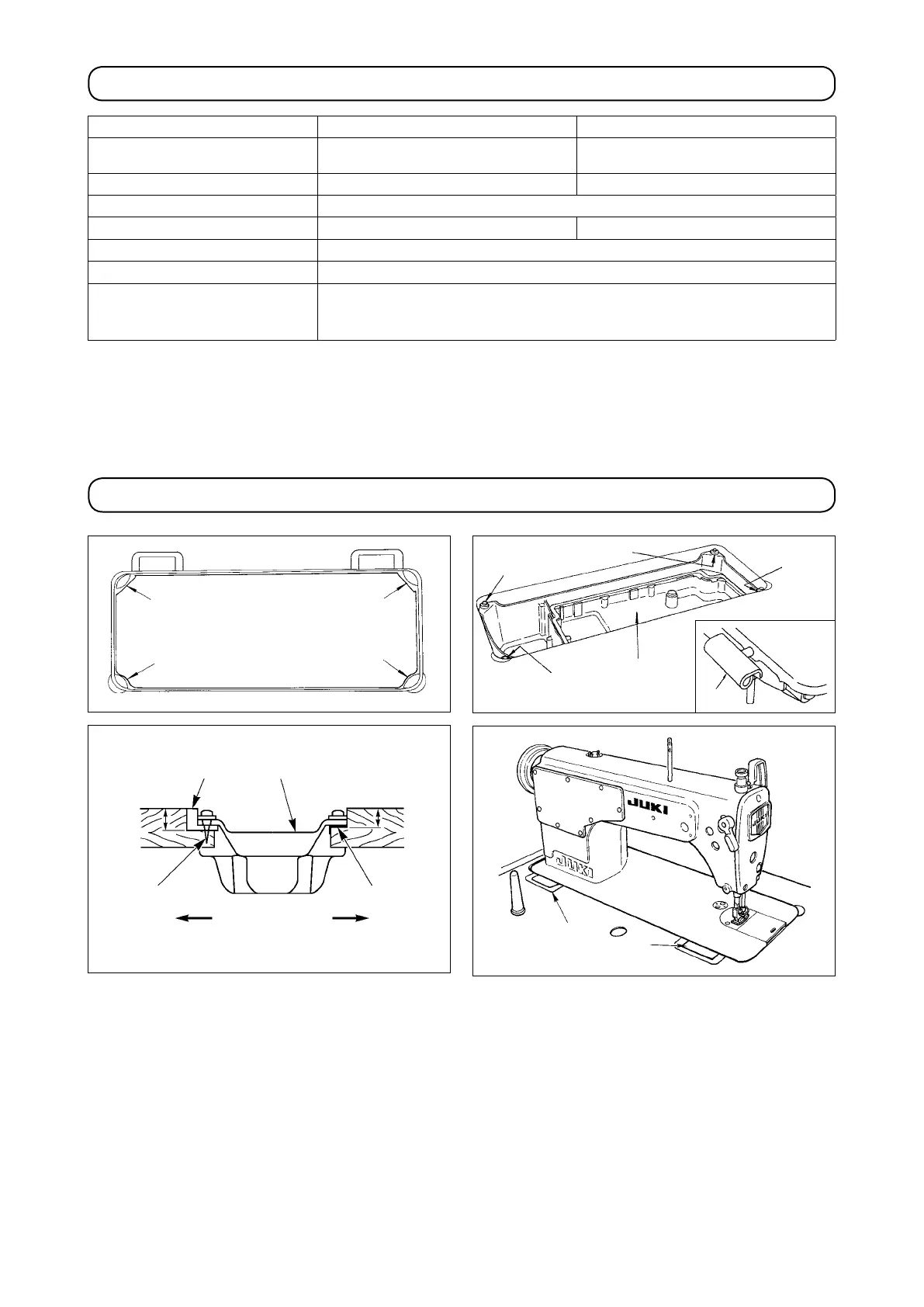

(1) Installing the oil pan

1) The under cover should rest on the four corners of the machine table groove.

2) Two rubber seats

1

for supporting the head portion on the operator side

A

are xed on the extended

portion of the table by hitting the nail

2

, and the other two rubber cushion seats

3

on the hinge side

B

are xed by using a rubber-based adhesive. Then, oil pan

4

is placed.

3)

Fit hinge

1

into the opening in the machine bed, and t the machine head to table rubber hinge

2

be-

fore placing the machine head on cushions

3

on the four corners.

2. INSTALLATION

DDL-8100e DDL-8100eH

Application

General fabrics, light-weight

and medium-weight materials

Medium-weight materials,

heavy-weight materials

Sewing speed Max. 4,500 sti/min Max. 4,000 sti/min

Stitch length Max. 5 mm

Needle DB x 1 #9 to #18 DA x 1 #20 to #23

Presser foot lift (by knee lifter) 10 mm (standard) 13 mm (Max.)

Lubricating oil JUKI MACHINE OIL #7

Noise

-

Equivalent

continuous emission sound pressure level (L

pA

) at the workstation:

A-weighted value of 80 dB; (Includes K

pA

=2.5dB); according to ISO 10821 - C.6.2-

ISO 11204 GR2 at 4,200 sti/min.

18.5 mm

22.5 mm

1

3

1

3

1

4

1

2

3

4

1

2

3

3

3

A

B

3

Loading...

Loading...