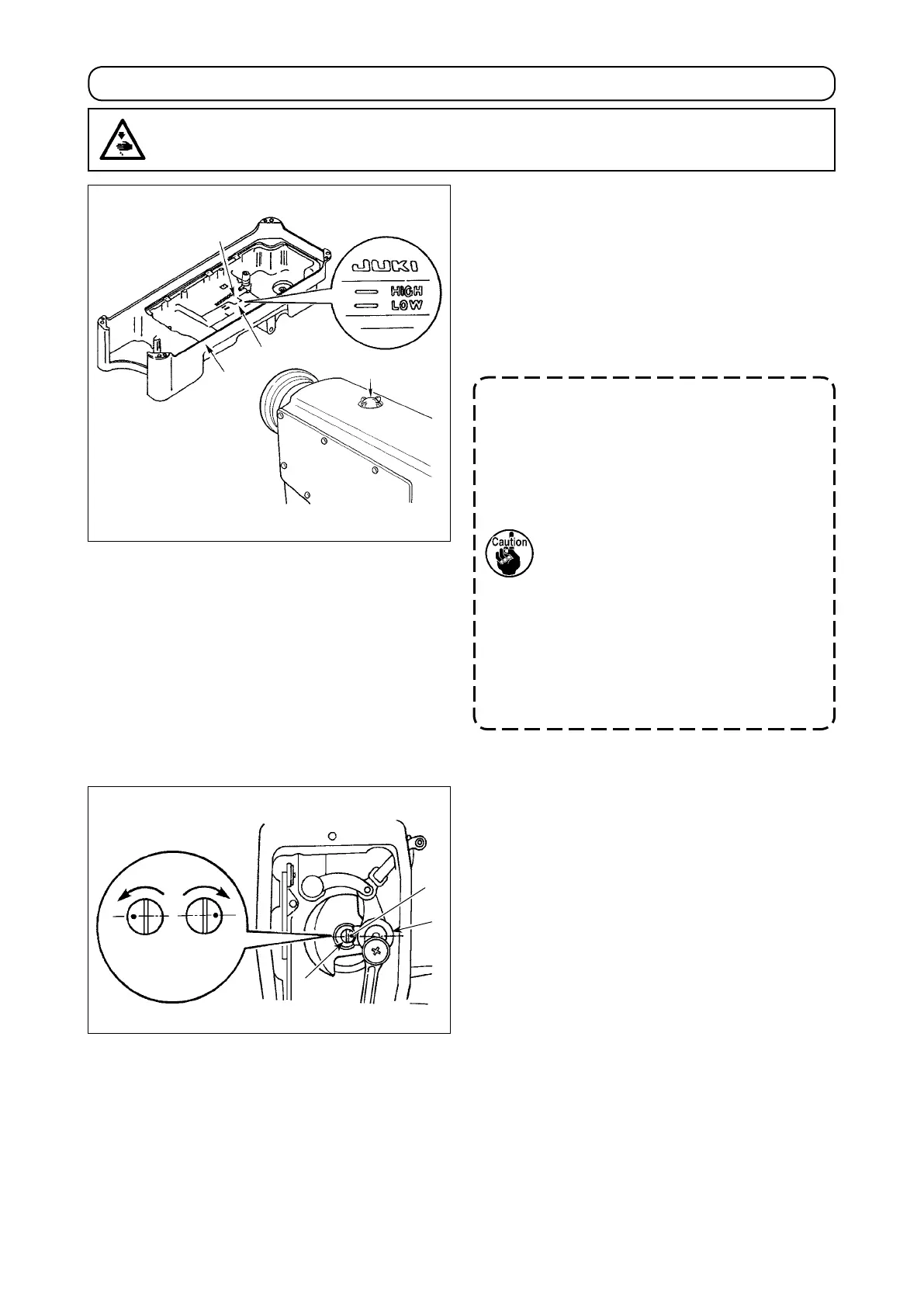

(2) Adjusting the amount of oil supplied

to the face plate parts

1) Adjust the amount of oil supplied to the thread

take-up and needle bar crank

2

by turning adjust

pin

1

.

2) The minimum amount of oil is reached when

marker dot

A

is brought close to needle bar

crank

2

by turning the adjust pin in direction

B

.

3) The maximum amount of oil is reached when

marker dot

A

is brought to the position just op

-

posite from the needle bar crank by turning the

adjust pin in direction

C

.

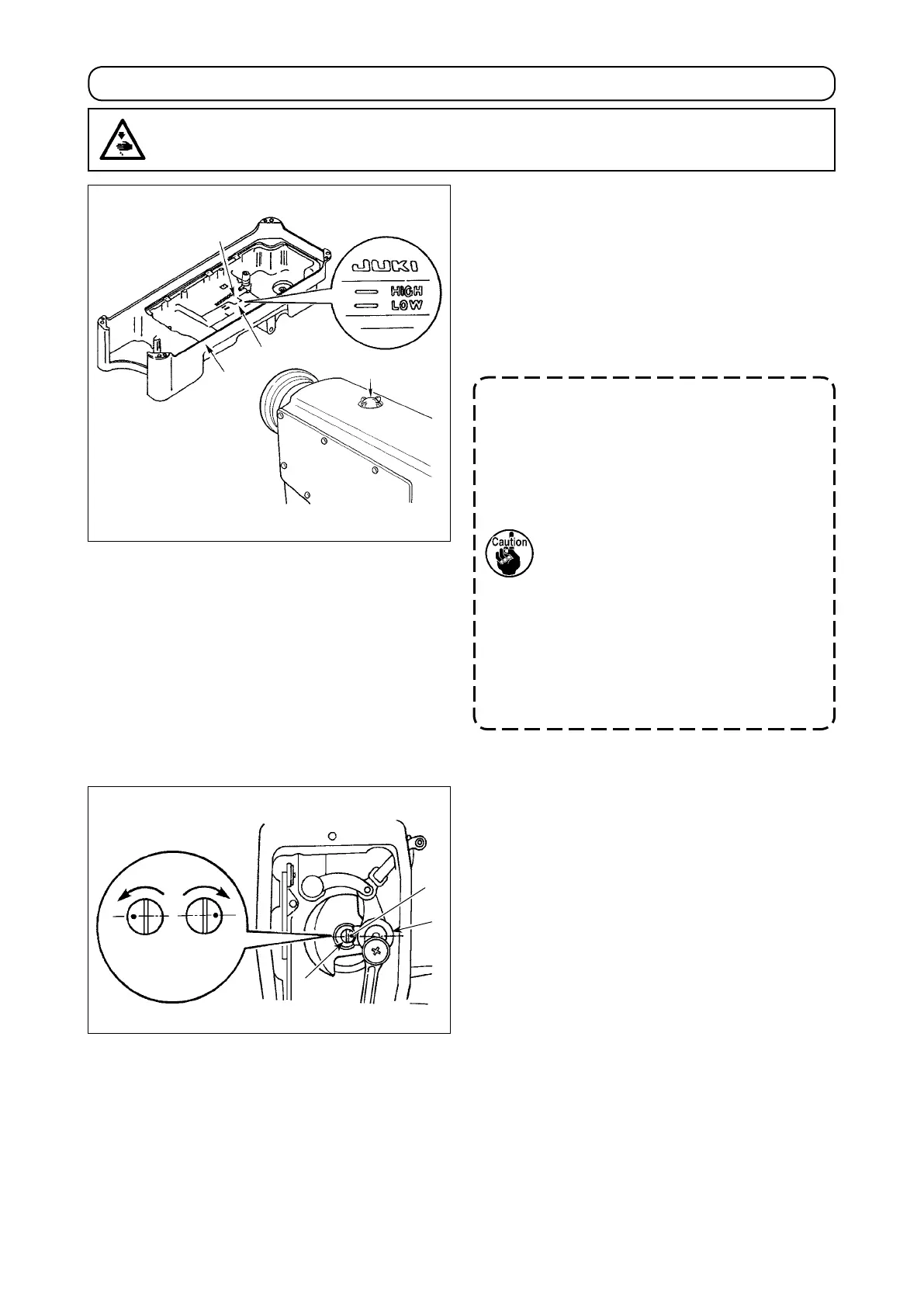

6. LUBRICATION

(1) Information on lubrication

1) Fill oil pan

1

with JUKI New Defrix Oil No. 1 up

to HIGH mark

A

.

2) When the oil level lowers below LOW mark

B

,

rell the oil pan with the specied oil.

3) When you operate the machine after lubrication,

you will see splashing oil through oil sight window

2

if the lubrication is adequate.

1. When you first operate your ma-

chine after setup or after an ex-

tended period of disuse, run your

machine at 3,000 sti/min to 3,500

sti/min for about 10 minutes for the

purpose of break-in.

2. When the machine is continuously

used at a low speed (2,000 sti/min

or less), make the machine run idle

at a high speed (4,000 sti/min or

more) for approximately 5 minutes

once a week. Use clean oil and

when the oil becomes dirty, replace

it with clean oil as soon as pos-

sible. When you continue to use the

machine with dirty oil, the trouble

will be caused.

Maximum

Minimum

WARNING :

To avoid possible personal injury due to abrupt start of the machine, turn off the power to the

machine and check to be sure that the motor has totally stopped rotating in prior.

1

A

B

2

1

C

B

1

A

2

Loading...

Loading...