RELATION BETWEEN THE HOOK AND THE NEEDLE

Match

the

needle with the sewing hook

as

tallows:

1.

Rotate the hand

wheel

and bring the needle

bar to its lowest position.

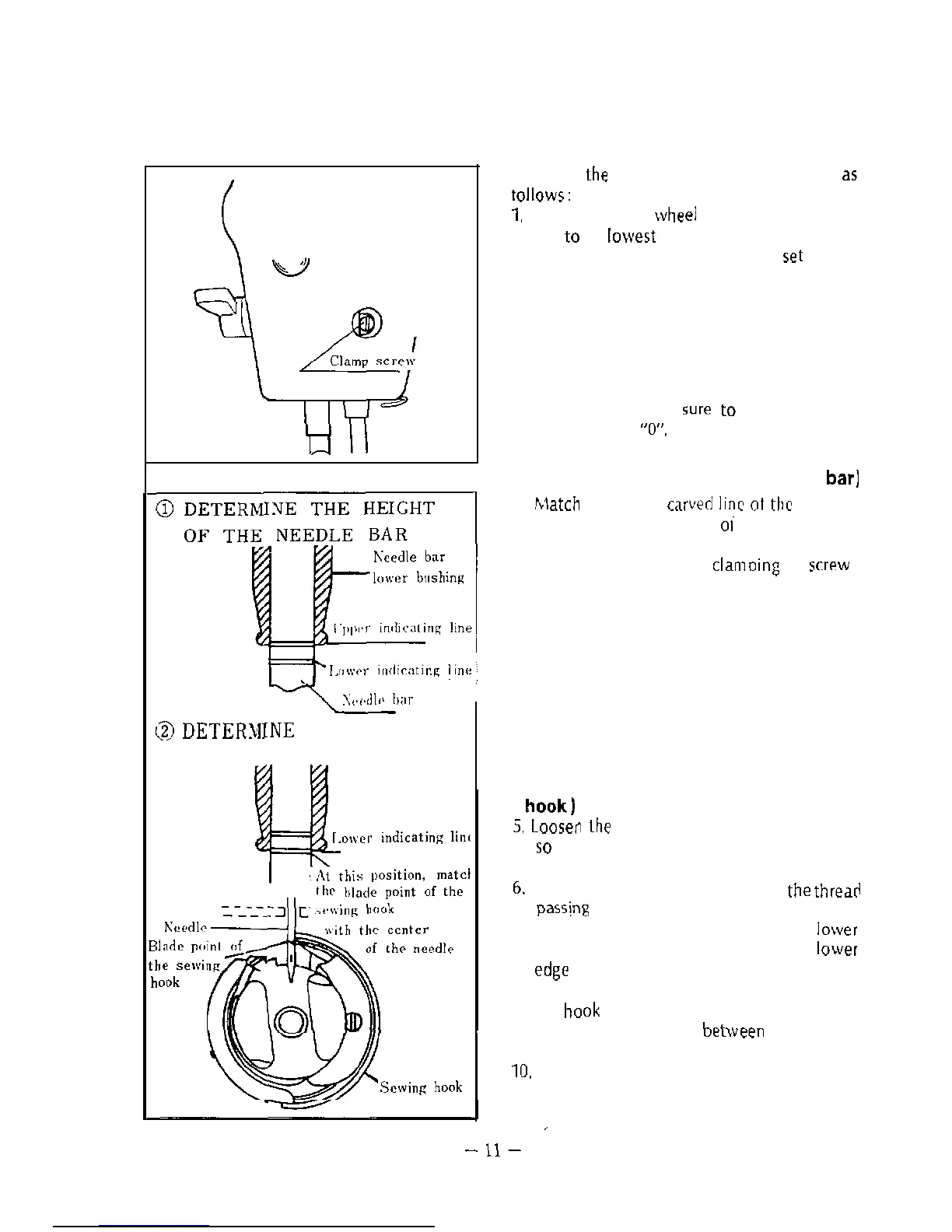

2. Loosen the needle bar clamping

set

screw.

(Note)

When matching the timing of the needle and

the sewing hook, be sure to ret the feed

adjusting dial to “0”.

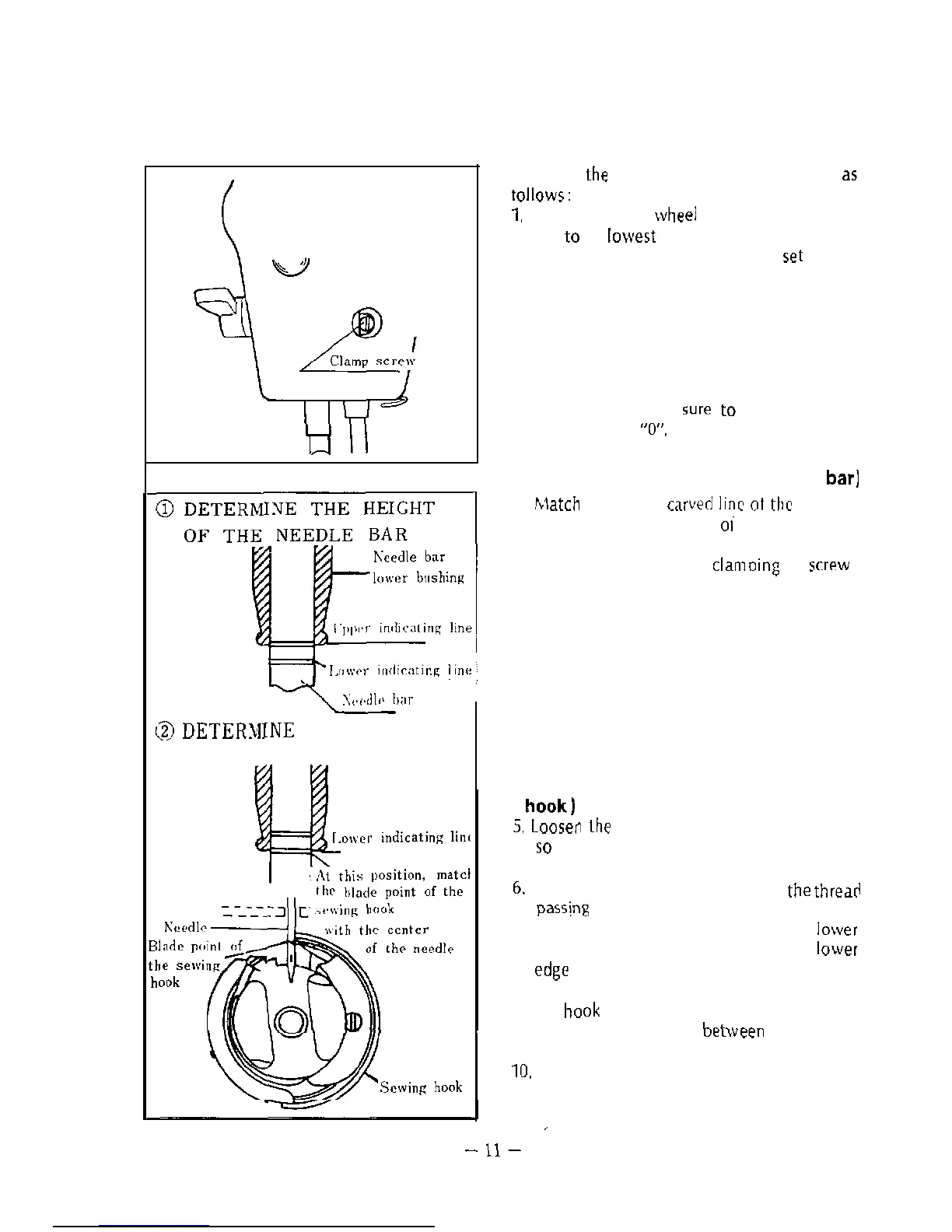

(Determine the height of the needle

bar]

3.

hlatch

the upper

c,,ived

linc

01

the

needle

bar with the lower edge

ai

the needle bar

low, bushing.

4. Tighten the needle bar

clamoing

ret

screw

3

DETER!vlINE THE POSITION

OF THE SEWING HOOK

7. Rotate the hand wheel and match the

lower

carved line of the needle bar with the

lower

edge

of the needle bar lower bushing.

8. In this condition. match the blade point of

the

haok

with the center line of the needle

9. Make the clearance

between

the needle

and the hook blade point to 0.05 mm and

10.

Securely tighten the hook clamping set

screw

(Determine the position of the sewing

hook)

5.

Laaren

the

3 clamping screws of the hook

so that the hook can be rotated freely with

the hand.

6.

Place the hook with your hand to thethread

pass/rig

position

Loading...

Loading...