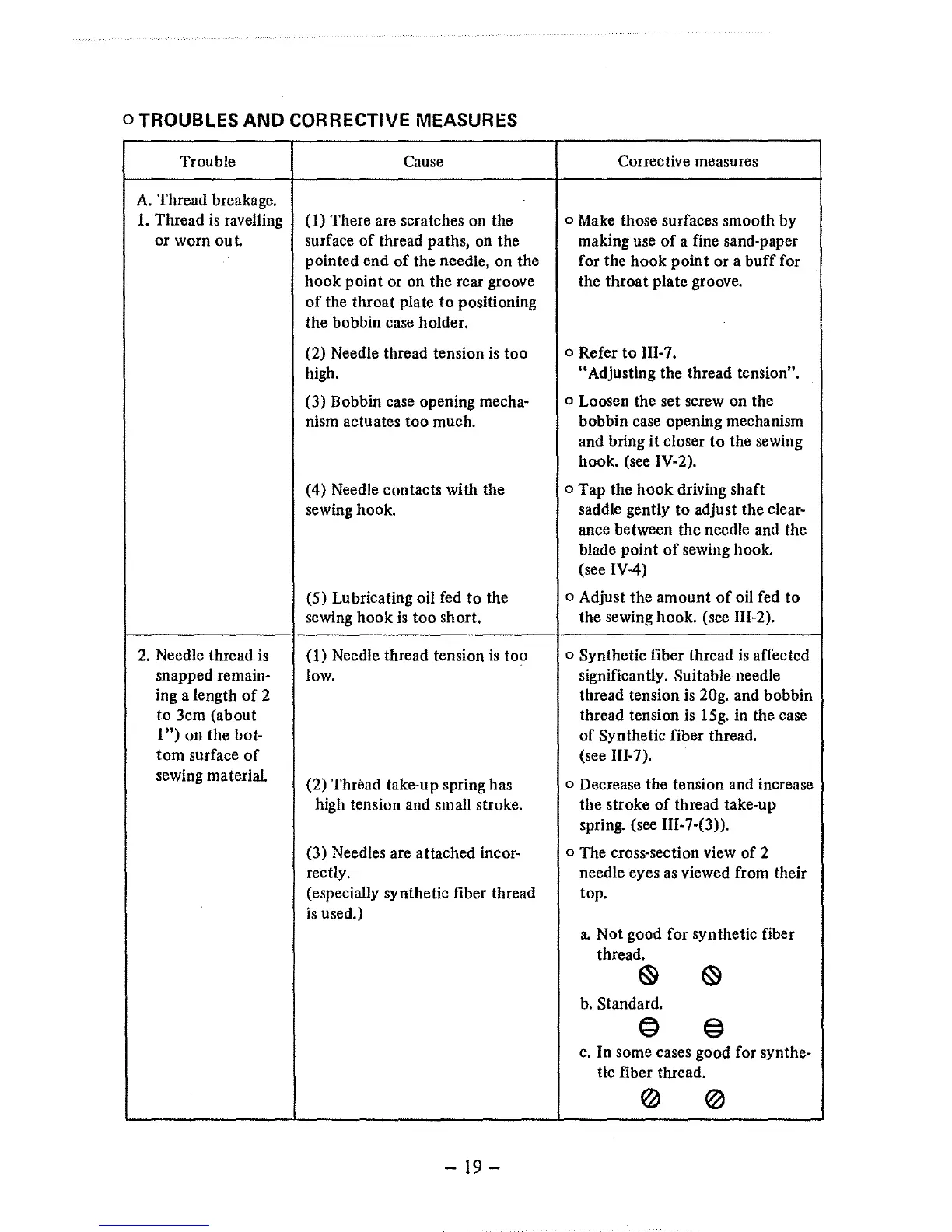

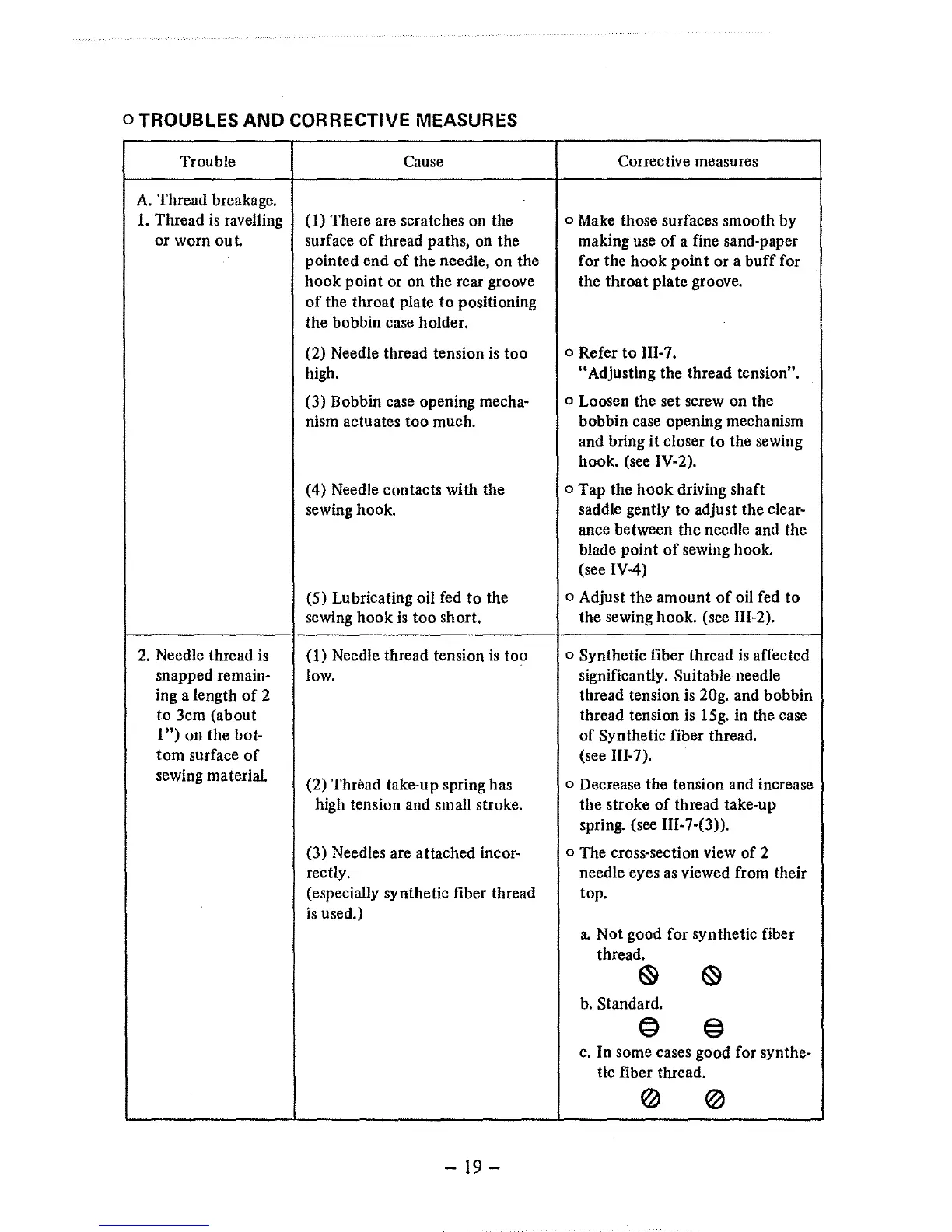

o TROUBLES

AND

CORRECTIVE MEASURES

Trouble

Cause

Corrective measures

A.

Thread breakage.

1.

Thread

is

ravelling

{1)

There are scratches

on

the o

Make

those surfaces smooth by

or worn

out

surface

of

thread paths,

on

the

making use

of

a fine sand-paper

pointed end

of

the needle, on the for the hook

point

or a buff for

hook point or on the rear groove the throat plate groove.

of

the throat plate

to

positioning

the bobbin case holder.

(2) Needle thread tension

is

too

o Refer

to

111-7.

high.

"Adjusting the thread tension".

(3) Bobbin case opening mecha-

o Loosen the set screw on the

nism actuates too much. bobbin case opening mechanism

and bring it closer

to

the sewing

hook. (see IV-2).

(4) Needle contacts with the o Tap the hook driving shaft

sewing hook.

saddle gently to adjust the clear-

ance between the needle and the

blade point

of

sewing hook.

(see IV-4)

(5) Lubricating oil fed

to

the

o Adjust the amount

of

oil fed to

sewing hook

is

too short.

the sewing hook. (see III-2).

2.

Needle thread

is

{1)

Needle thread tension

is

too

o Synthetic fiber thread

is

affected

snapped remain-

low.

significantly. Suitable needle

ing a length

of

2

thread tension is

20g. and bobbin

to

3cm (about

thread tension

is

15g. in the case

1") on the bot-

of Synthetic fiber thread.

tom

surface

of

(see III-7).

sewing material.

(2) Thread take-up spring has

o Decrease the tension and increase

high tension and small stroke.

the stroke

of

thread take-up

spring. (see

111-7-(3)).

(3)

Needles are attached incor- o The cross-section view of 2

rectly.

needle eyes

as

viewed from their

(especially synthetic fiber thread top.

is

used.)

a.

Not good for synthetic fiber

thread.

~

~

b.

Standard.

~

§

c.

In some cases good for synthe-

tic fiber thread.

@

@

-

19-

Loading...

Loading...