Ill.

HOW TO OPERATE THE MACHINE

1.

LUBRICATION

The

amount

of

oil

to

lubricate

the

face

plate mechanism has normally been ad-

justed at

our

factory before shipment.

If

necessary, you may adjust it

by

turning

the

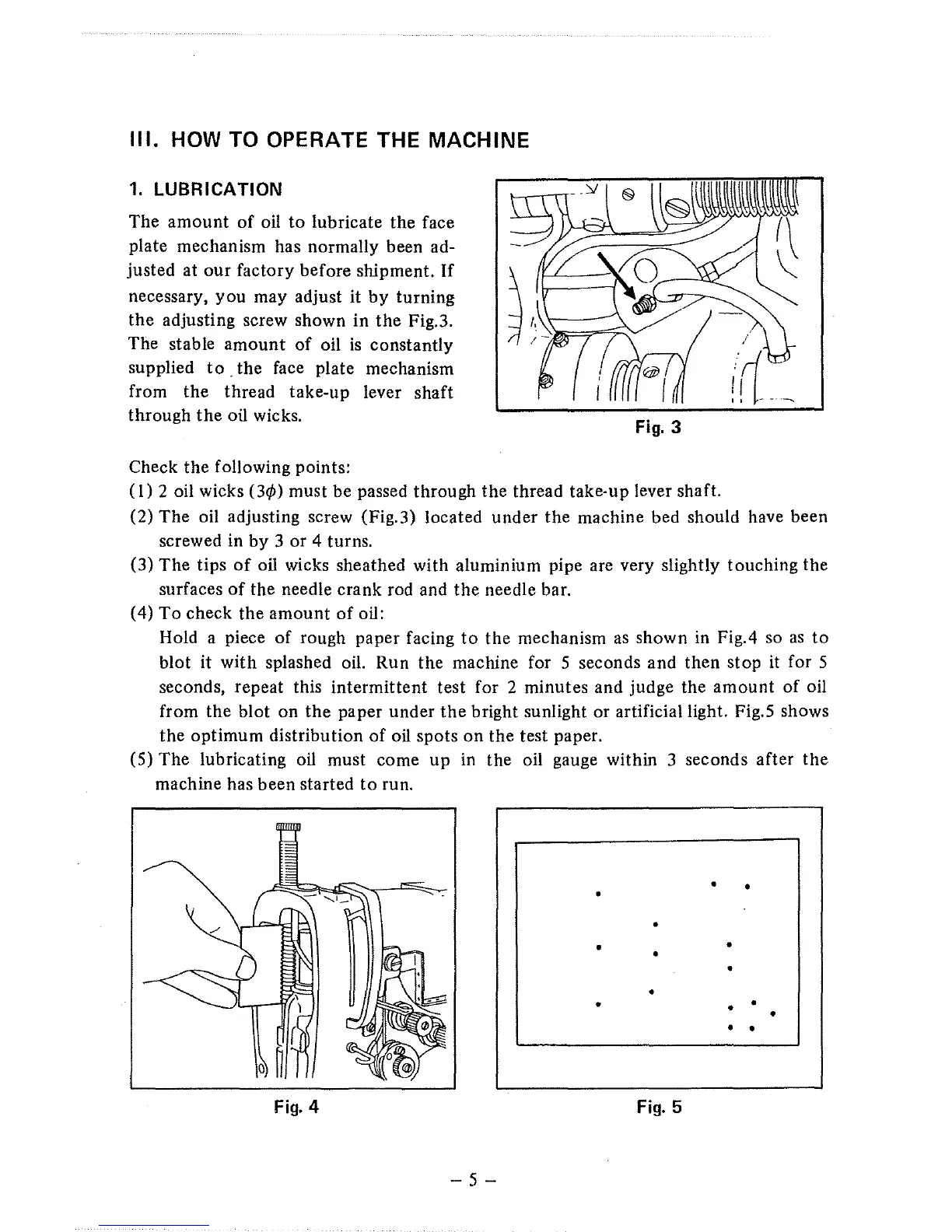

adjusting screw shown in

the

Fig.3.

The stable

amount

of

oil

is

constantly

supplied

to

. the face plate mechanism

from

the

thread take-up lever shaft

through

the

oil wicks.

Check the following points:

Fig.

3

(I)

2 oil wicks

(3c/>)

must be passed through

the

thread take-up lever shaft.

(2)

The

oil adjusting screw (Fig.3) located under the machine bed should have been

screwed in

by

3 or 4 turns.

(3)

The

tips

of

oil wicks sheathed with aluminium pipe are very slightly touching the

surfaces

of

the needle crank rod and

the

needle bar.

(4)

To

check the amount

of

oil:

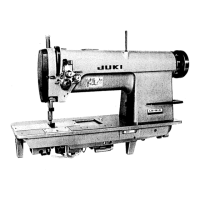

Hold a piece of rough paper facing

to

the mechanism

as

shown

in

Fig.4 so

as

to

blot

it

with

splashed

oiL

Run the machine for 5 seconds and then stop it for 5

seconds, repeat this intermittent test for 2 minutes and judge the amount of oil

from the blot on

the

paper under

the

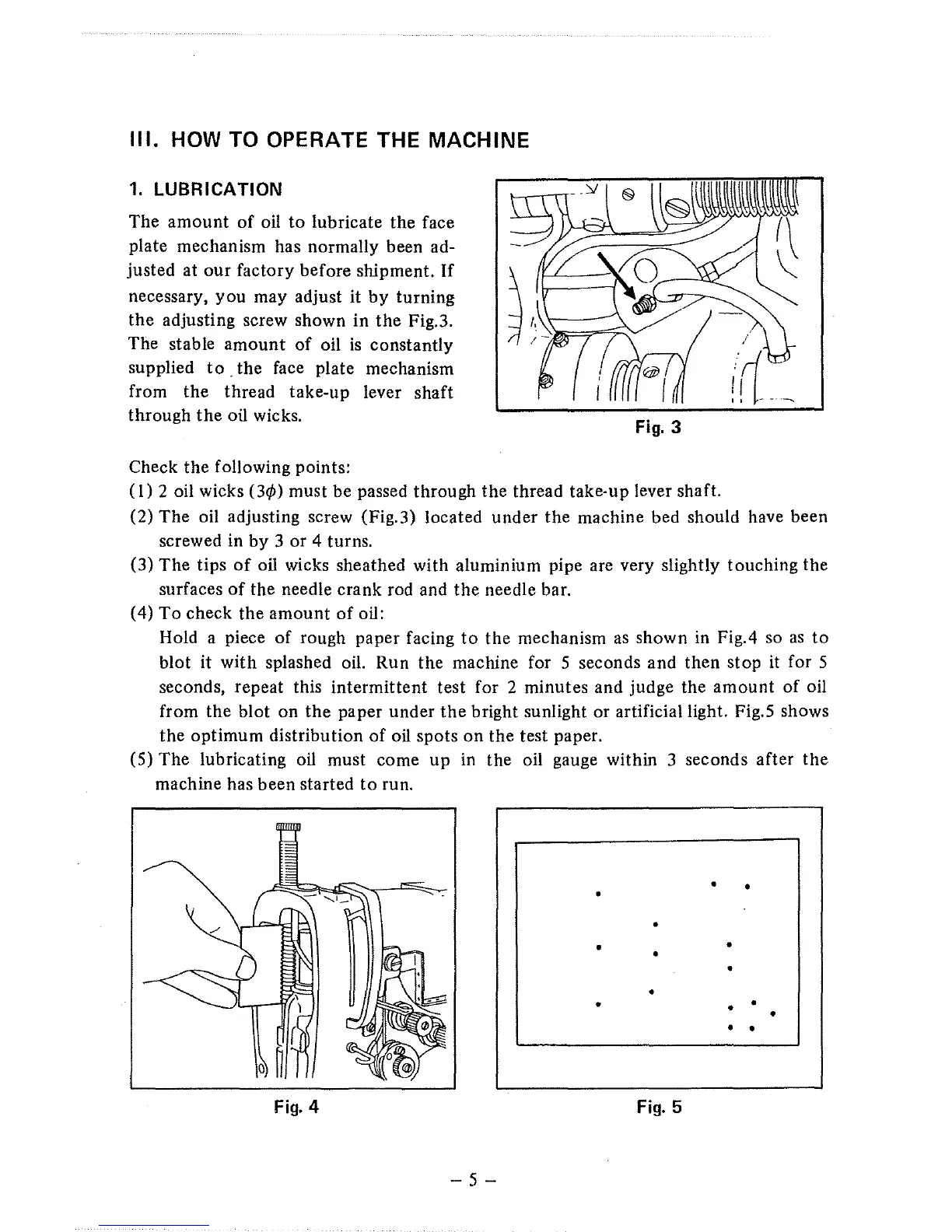

bright sunlight or artificial light. Fig.5 shows

the optimum distribution

of

oil spots on the test paper.

(5) The lubricating oil must come up in the oil gauge within 3 seconds after

the

machine has been started

to

run.

• •

Fig.

4

Fig.

5

-5-

Loading...

Loading...