– 10 –

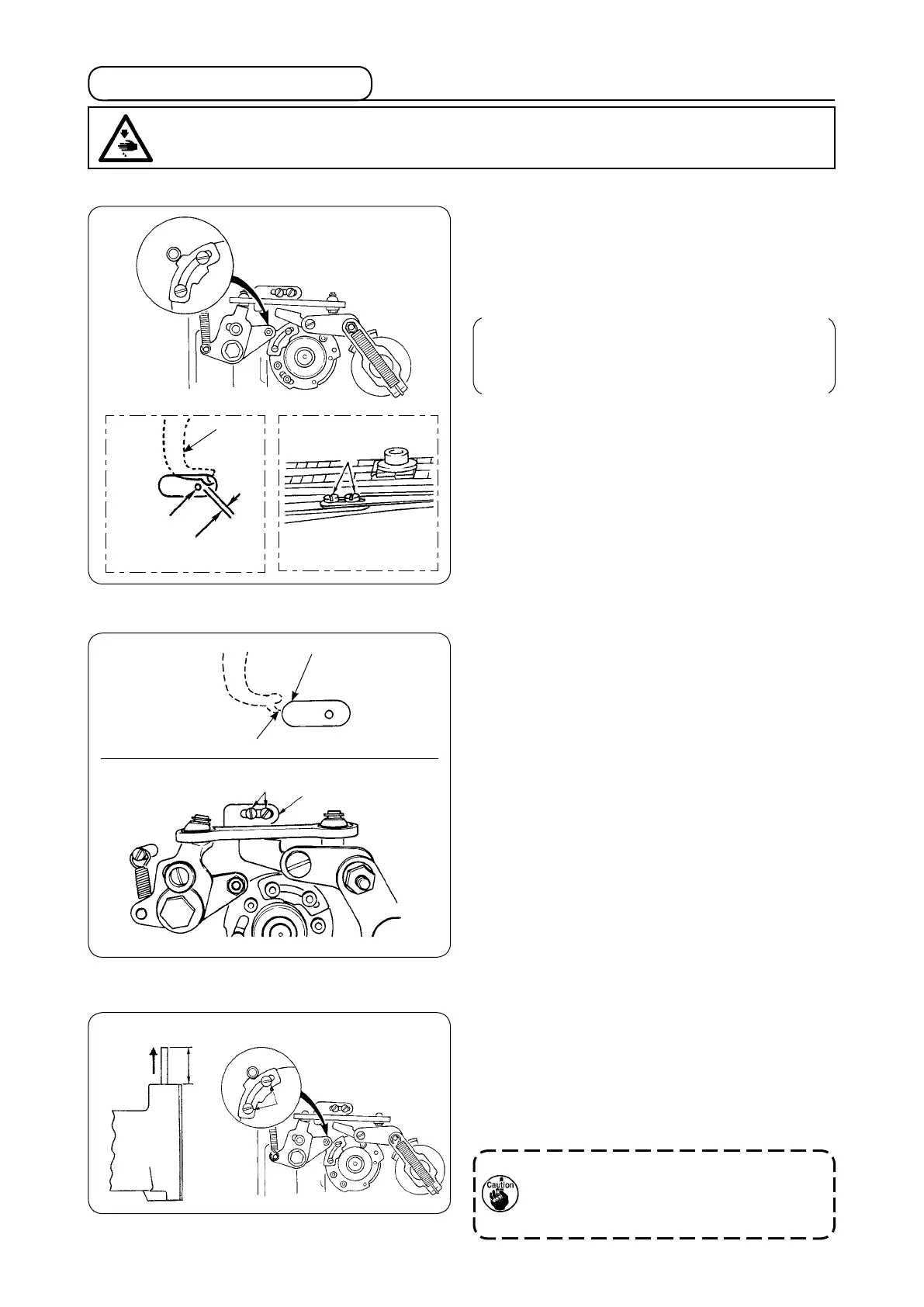

3-18. Knot-tying mechanisms

(1) Adjusting the knot-tying connecting plate

Loosen screws

1

and adjust so that a clearance of

1 to 1.5 mm

is provided between the needle

2

and

the knot tying plate

3

when the roller of the knot-

tying arm gets on the outmost periphery of the knot-

tying notch.

After the adjustment, ascertain that the needle

does not come in contact with the knot-tying

plate.

(2) Adjusting the knot-tying arm stopper

When starting the sewing machine and the roller of

knot-tying arm does not come into contact with the

knot-tying notch, loosen screws

3

and adjust w

ith

stopper

4

so that outside periphery

1

of the needle

hole almost aligns with top end

2

of the knot-tying

plate.

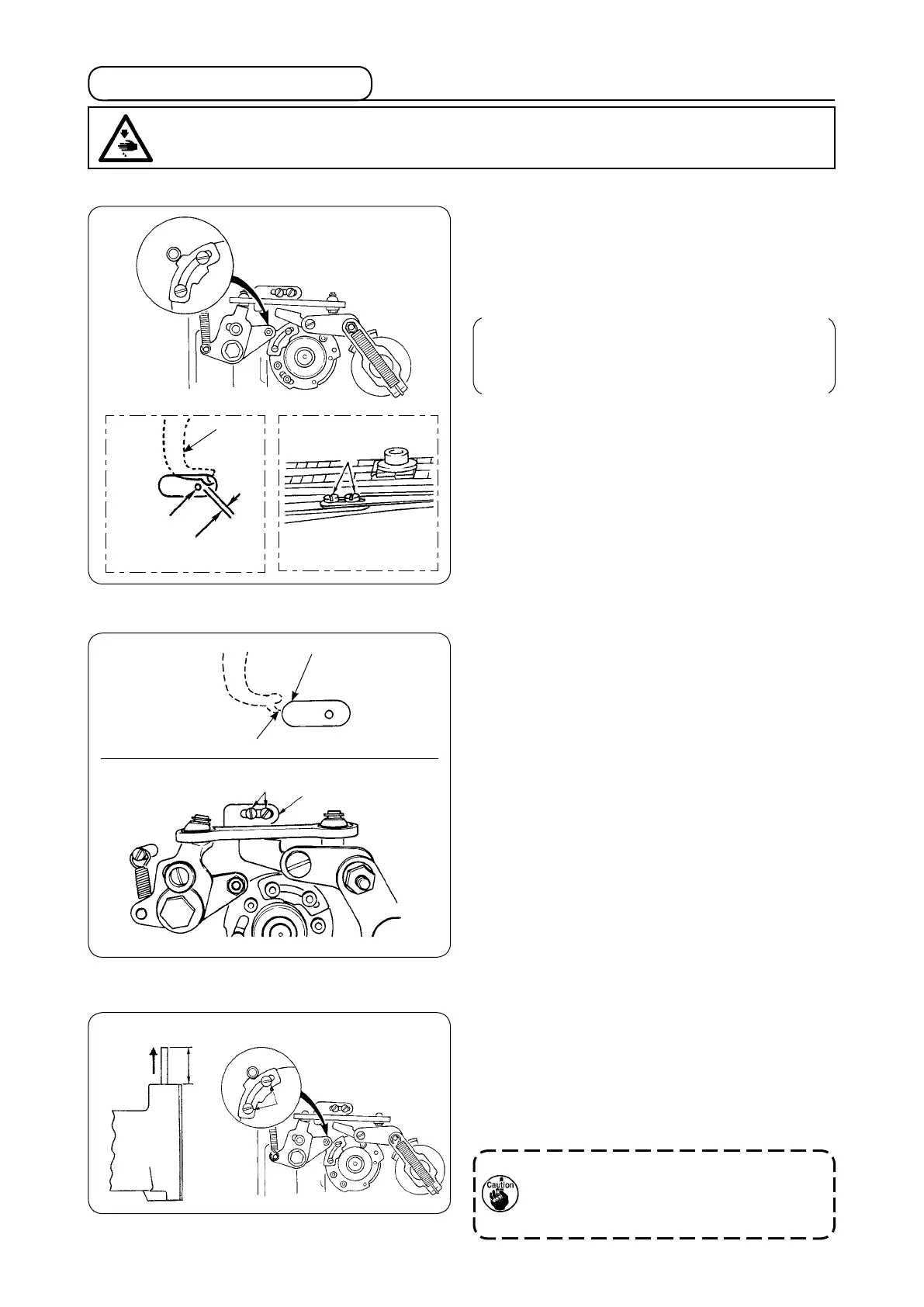

(3) Adjusting the knot-tying notch

Loosen screws

1

and adjust so that the roller of the

knot-ty

ing arm comes in contact with the knot-tying

notch when the needle bar goes up at the fourteenth

stitch as high as 30 to 35 mm (40 to 45 mm when a

TQ x 7 needle is used) above the needle bar upper

bushing.

If two knot-tying notches are to be installed

(w i t ho u t c r o s s o v e r st i t c h ) , m ak e t h e

aforementioned adjustment at the 6th and

14th stitches.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1 to 1.5 mm

2

1

3

2

1

3

4

30 to 35 mm

1

Loading...

Loading...