– 13 –

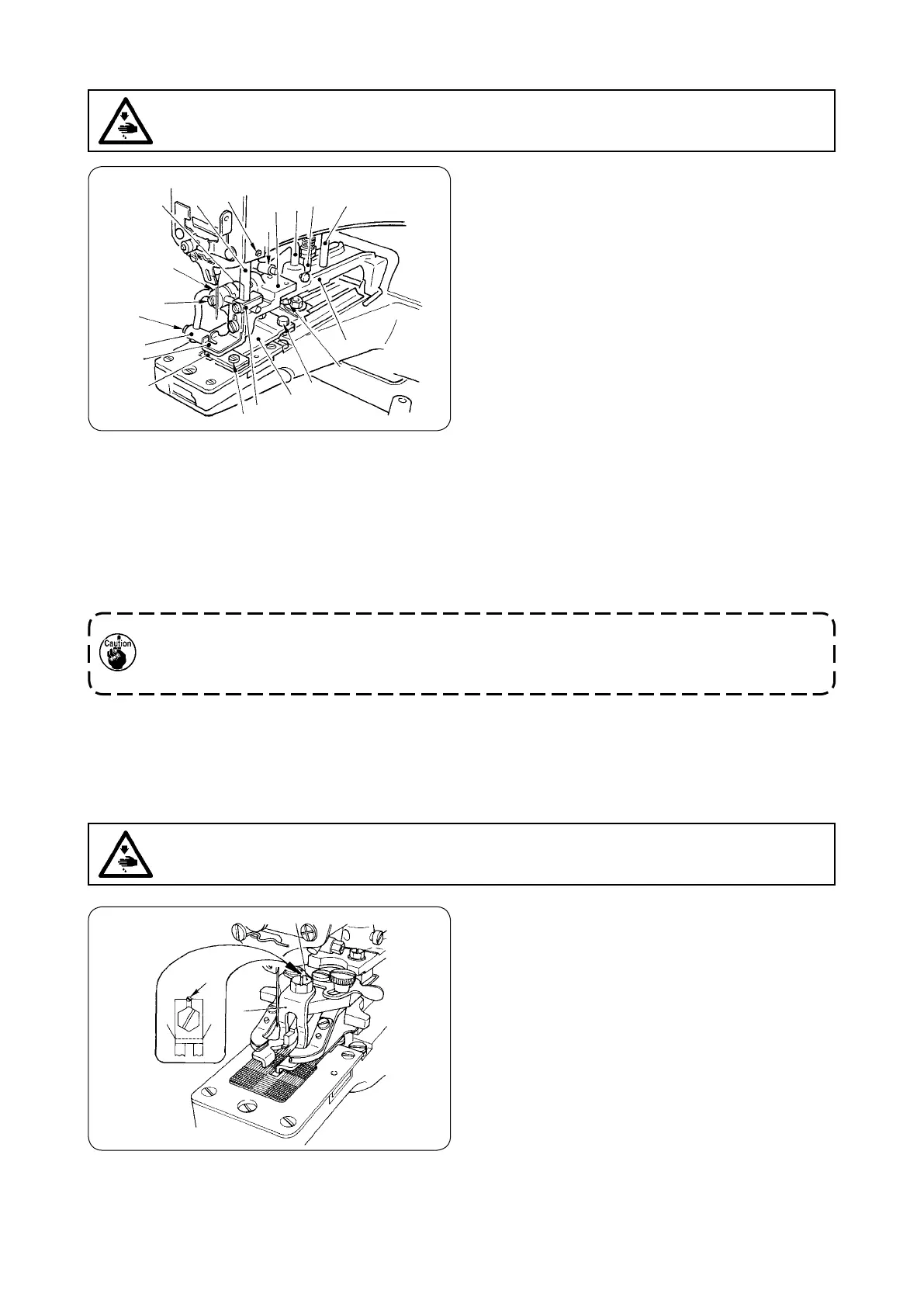

(1) Attachments for shank buttons (Pearl buttons) (Z033)

(INSTALLATION)

Remove both the button clamp mechanism assem-

bly and the feed plate from the mach

ine and install

attachment

1

in place. Loosen screws

3

and adjust

button clamp bracket

4

to permit the needle to

come down in the middle of the needle slot in shank

button adaptor

2

. Attach button clamp feed plate

5

us

ing screws

7

in the way that it permits the needle

to come down in the middle of the needle slot in feed

plate

6

. Insert the top end of button clamp stud

8

i

nto an opening in the jaw of the machine arm and

fasten it by screw

9

.

(ADJUSTMENT AND OPERATION)

(2) Attachment for the rst process of wrapped-around buttons (Z041)

1) Loosen screw

!2

, let feed plate

6

recede 0.5 to 1.0 mm from the left end of button clamp jaw lever

2

and ret

ighten screw

!2

.

2) Set a button in place, loosen screws

!3

and

!4

and align shank button holding clamp

!5

with the center of

the button.

3)

Shank button holding clamp

!5

must g

ive proper pressure to the button so that the button stays steadily

in position while being sewn. Loosen a setscrew in thrust collar

!6

and rotate the thrust collar until shank

button holding clamp

!5

provides proper pressure.

4) You may x button clamp block

!7

in a convenient position for operation.

1. When you x the thrust collar, ensure that button clamp rotating shaft

!8

does not play axially in its

bracket.

2.

Adjust lifting hook

@0

and stopper pin

!1

so that L-shaped lifting rod roller

!9

does not come in

contact with button clamp bracket

4

.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

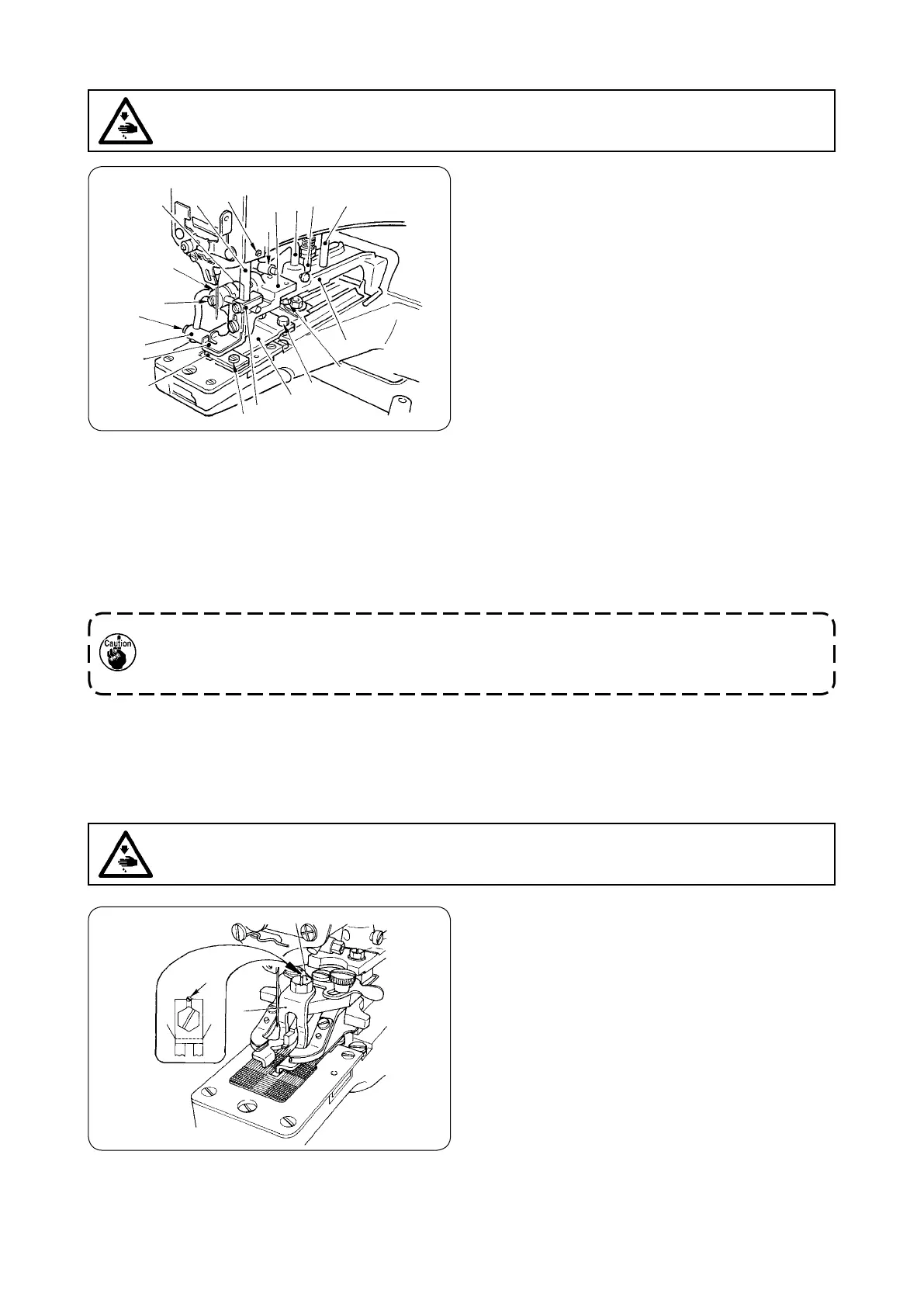

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(INSTALLATION)

Attach wrapped-around button foot

1

to the ord

inary

button clamp jaw levers using screw

2

and guide

pin screw

3

.

Align foot

1

with the jaw levers so that they permit a

button to rest in the middle.

(ADJUSTMENT AND OPERATION)

Adjustment and operation are almost same as those

for the at buttons, but you must adjust the thread

pull-off lever to provide more amount of thread in

order to make the thread loose below the button for

thread shank formation. (refer to

"3-2.

Adjustment of

the thread pull-off lever

", p.4

)

1

2

4

3

6

7

8

9

!0

!1

!2

!3

!4

!5

!6

!7

!8

!9

@0

5

1

2

3

Loading...

Loading...