+

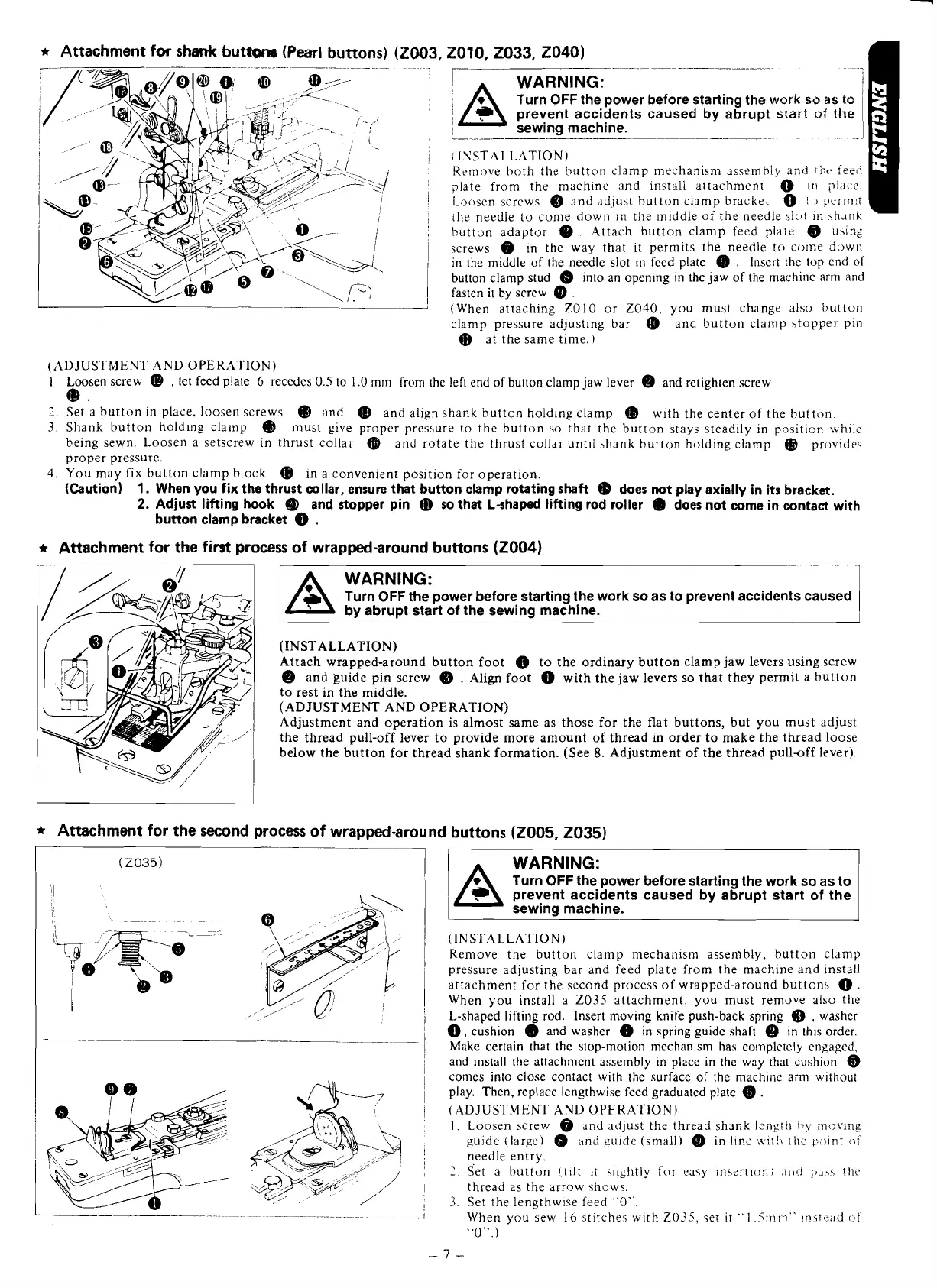

Attachment for

shank

buttor#

(Pearl

buttons)

-

-

-

--

-

-

-

-

-.

-

-

-

A

WARNING:

Turn

OFF the power before starting the

wvrk

so

as

to

prevent accidents caused by abrupt

start

of

the

sewing machine.

--

-.

-

-

--

-

-.

--

--

-

-

:

ISSTALLATION)

Rrmove both the button clamp mechanism ~ssemhiy ant!

1

iir.

teed

?late from the mach~ne and install attachment

0

111

plaL:e.

i20i,sen screws

&)

and adjust button clamp brackzt

@

11,

perrn:r

the needle to come dow11 in the middle of the needle slc~t In

hh~r~k

button adaptor

e)

.

Attach button clamp feed plate

6)

uhing

screws in the way that it permits the needle to come a!>wrl

in the middle of the needle slot in feed plate

a)

.

Insert the top end

ol"

button clamp stud

@

into an opening in the jaw of the machine arm and

fasten

it

by screw

8)

.

(When attaching

ZOlO

or

2040,

you must change also button

clamp pressure adjusting bar

@

and button clamp >topper pin

@

a! the same time.)

(,ADJUSTMENT AND OPERATION)

1

Loosen screw

(B

,

let feed plate

6

recedes 0.5 to 1.0 mm from the left end of button clamp jaw lever

@

and retighten screw

(B.

2.

Set a button in place. looser~ screws

@

and

g)

and align shank button holding clamp

@

with the center of the button.

3.

Shank button holding clamp

@

must give proper pressure to the button so that the button stays steadily in posit~on xvhile

being sewn. Loosen a setscrew in thrust collar

@

and rotate the thrust collar until shank button holding clamp

@

provide

proper pressure.

4.

You may fix button clamp block

@

in a

convenient

position for operation.

(Caution)

1.

When you fix the thrust collar, ensure that button clamp rotating shah

@

does not play axially in

its

bracket.

2.

Adjust lifting hook

@

and stopper pin B) so that L-shaped lifting rod roller

@I

does not come in contact with

button clamp bracket

@

.

t

Attachment for the fint process of wrapped-around buttons (2004)

A

WARNING:

Turn OFF the power before starting the work so as to prevent accidents caused

by abrupt start of the sewing machine.

(INSTALLATION)

7

Attach wrapped-around button foot

0

to the ordinary button clamp jaw levers using screw

@

and guide pin screw

6)

.

Align foot

with the jaw levers so that they permit

a

button

to rest

in

the middle.

(ADJUSTMENT AND OPERATION)

Adjustment and operation is almost same as those for the flat buttons, but you must adjust

the thread pull-off lever to provide more amount of thread

in

order to make the thread loose

below the button for thread shank formation. (See

8.

Adjustment of the thread pull-off lever).

i

*

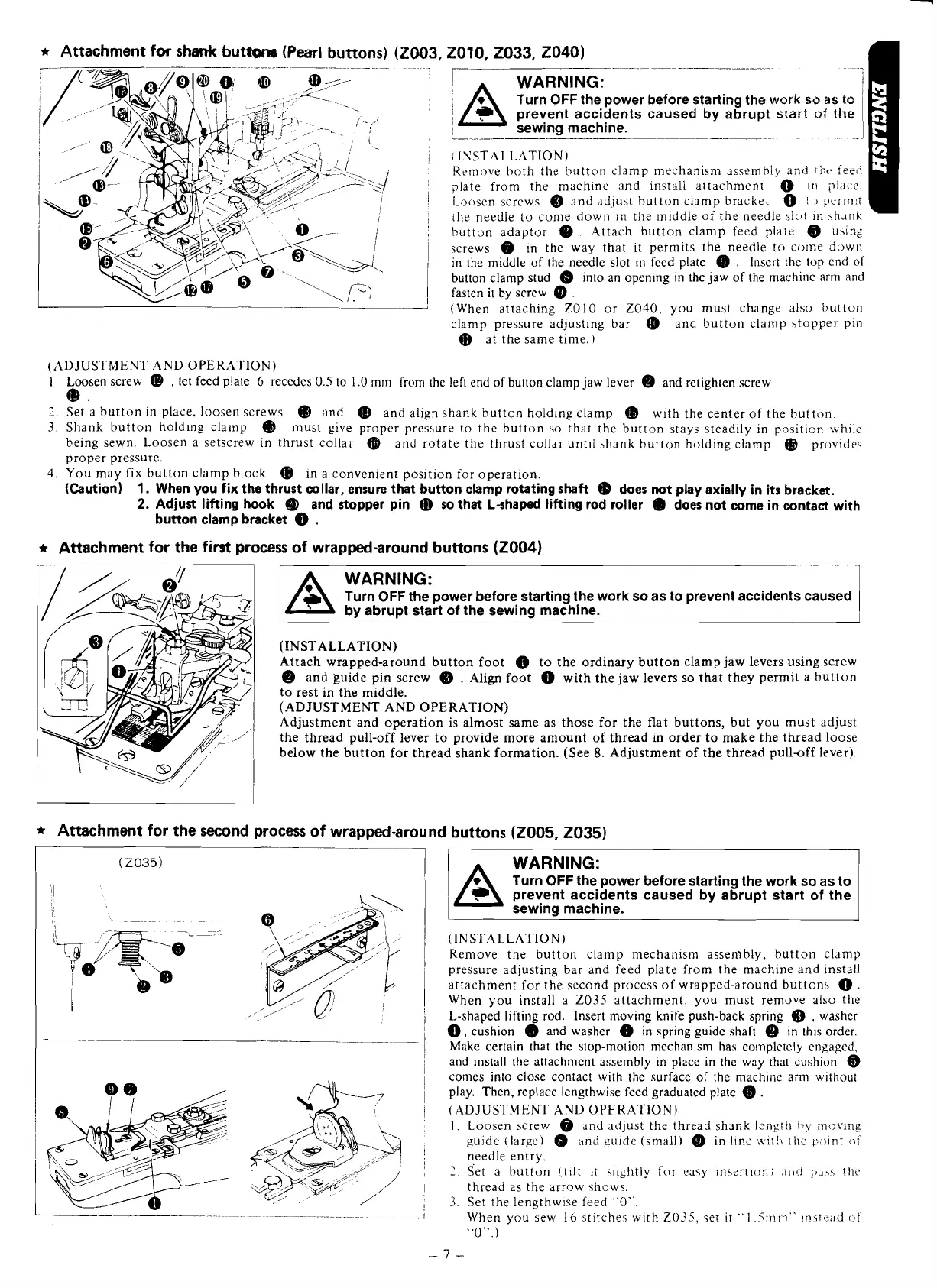

Attachment for the second process of wrapped-around buttons (2005,2035)

--

(2035)

;I

1

Turn OFF the power before starting the work so as to

prevent accidents caused by abrupt start of the

I,

-

~

-

-

I

(INSTALLATION)

E

When you install

a

2035 attachment, you must remove also the

,

,

/,/'

I

L-shaped lifting rod. Insert moving knife push-back spring

6)

,

washer

I

0,

cushion

@

and washer

@

in spring guide shaft

e)

in this order.

-

1

1

Make certain that the stop-motion mechanism has co~npletcly engaged,

!

and install the attachment asseinbly in place in the way that cushion

@

1

corncs into close contact with the surface of the machine arin without

i

play. Then, replace lengthwise feed graduated plate

a)

.

i

(ADJUSTMENT AND OPFKATION!

:

1.

Loosen screw

@

~nd adjust the thread shsnk lcngtli

by

rnovine

guide (large)

snd guide (small)

8)

in Iinc ;vi!ii [he p:)int

of

n.eedle entry.

,

-.

Set a button

(ti1

t

lr

slightly

for

easy inserrion;

.~iiti

~J,S

!tic

thread as the arrow shows.

1

3.

Set the

lengthwise

feed

"0".

.-

~-

.--

--

~

L

When you sew I6 stitches with

ZO35,

~et it

"I

.51n1n"

~v.;r<:;iti

of

"O".)

Loading...

Loading...