-

-

[

12.

HEIGHT

~F-THE

1

13.

WORK~RE~~SING~

114.

ADJUSTMENT

OF

I

I

L-

BUTTON

--

CLAMP!

---

L

FORCE

---

I

THE BUTTON

CLAMP

STOP

LEVER!

Turn

OFF

the power before

start~ng

the

WARNING:

I

Turn

OFF

the power before

starting

the

1

9

work

so

as

to

prevent accidents caused

17

I_?

by

abrupt

start

of the sewing machine.

1

--

h

-2

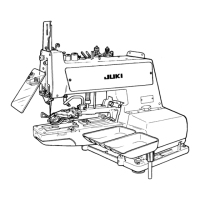

The standard clearance

@

between the

bottom face of button clamp jaw lever

@

and the top face of feed plate

@

is

-

12 mrn for

MB-373

and

9

mn? for

MB-373.

Loosen screw

@

and adjust the height of

button clamp lifting hook

.

The

standard work pressing force is obtaincd

by providing a

4

to

5

mm

clearance between

the bottom face of nut and the bottom

end of the screw of pressure adjusting bar

e.

1

TENSION

RELEASE

I

d

WARNING:

I

Turn

OFF

the power before starting the work so as

to prevent accidents caused by abrupt start of the

sewina machine.

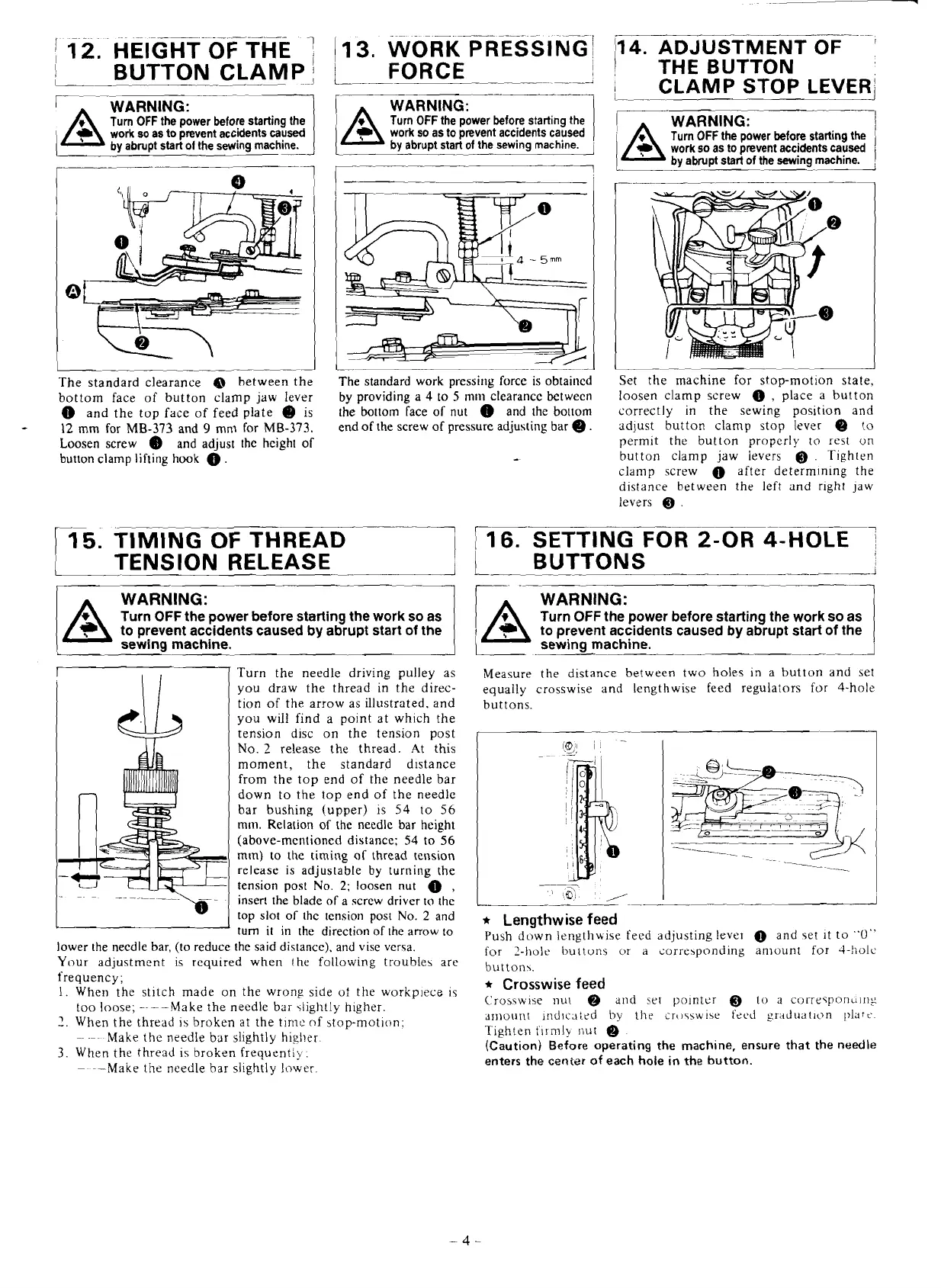

Turn the needle driving pulley as

you draw the thread in the direc-

tion of the arrow as illustrated. and

you will find a point at which the

tension disc on the tension post

No.

2

release the thread. .4t this

moment, the standard

d~stance

from the top end of the needle bar

down to the top end of the needle

bar bushing (upper) is

54

to

56

mm. Relation of the needle bar height

(above-mentioned distance;

54

to

56

mtn) to the timing

ol

thread tension

release is

adjuslable

by

turning the

tension post No.

2;

loosen nut

0

,

insert the blade of a screw driver to the

top slot of

thc tension post No.

2

and

turn it in the direction of the arrow to

lower the needle bar, (to reduce the said

distance). and vise versa.

Your adjustment

is

required when the following troubles are

frequency;

1.

When the stitch made on the wrong side

of

the workp~ece ic

too loose; ----Make the needle bar slightly higher.

2.

When the thread is broken

at

the

time

of stop-motion;

-. .-

~

Make the needle bar slightly

higher.

3.

When the thread is broken frequent!!,

.

-

-Make the needle bar slightly lower.

I

I

Set

the machine for stop-motion state,

loosen clamp screw

,

place a button

correctly in the sewing position and

adjust button clamp

stop

lever

@

to

permit the button properly

to

rest

on

button clamp jaw levers

Q

.

Tighten

clamp screw

@

after determ~ning the

distance between the left and right jaw

levers

Q

.

7

p6

s

ETT~-GFOR-ZO~~H~

L

BUTTONS

J

WARNING:

Turn

OFF

the power before starting the work so as

to prevent accidents caused

by

abrupt start of the

sewing machine.

--

__-_I

1

Measure the distance between two holes in a button and set

equally crosswise and lengthwise feed regulators for 4-hole

buttons.

I

I

-.___-

*

Lengthwise feed

Puhh down Iength~ise feed ddjustlng lever

@

and set it to

'0''

for

2-hole

button5 or

d

iorre5pondlng dnluunt for

.I-!idlc

button\.

*

Crosswise feed

Crusswrse

nut

Q

and

rer

polntcr

Q

to

a

corresponuirig

arnourlr

ind~ca:ed

by

the

crosswise

frcd

graduation

plat^..

'Tighten

flrmly

i~ut

@

(Caution) Before operating the machine, ensure that the needle

enters

the

center

of

each hole in

the

button.

Loading...

Loading...