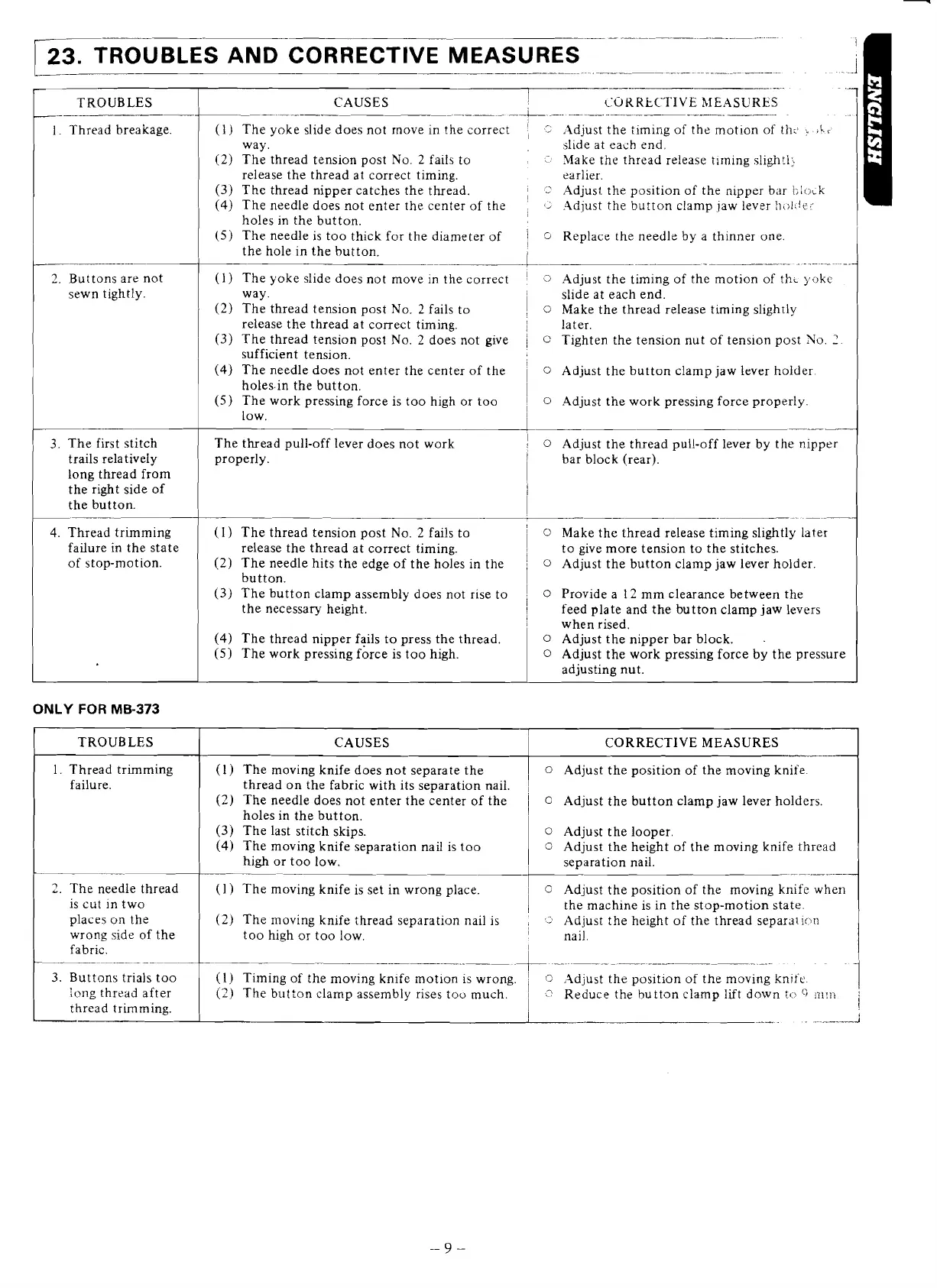

TROUBLES

1

1

Thread breakage

2.

Buttons are not

sewn tightly.

CAUSES

I

COKKtCTIVE hIEASURES

--&

~~

(1) The yoke slide does not rnove in the correct

:

'2

Adjust the timing of the motion of

tilt;

:

,\.c

way. slide at each end.

(2) The thread tension post No. 2 fails to

L-,

Make the thread release timing slightl:

release the thread at correct timing. earlier.

(3)

The thread nipper catches the thread.

I

2

Adjust the position of the nipper b;lr

i:ll.;;k

(2

Adjust the button clamp jaw lever

:~,>i:!i;t.

(4) The needle does not enter the center of the

!

'1

holes in the button.

(5)

The needle is too thick for the diameter of

j

'3

Replace the needle by a thinner one.

the hole in the button.

I

i

(1) The yoke slide does not move in the correct

3

Adjust the timing of the motion of th~

yoke

way. slide at each end.

(2)

The thread tension post No.

2

fails to

!

0

Make the thread release timing slightly

release the thread at correct timing.

I

later.

(3) The thread tension post No. 2 does not give

/

Tighten the tension nut of tension post No.

7.

sufficient tension.

i

(4)

The needle does not enter the center of the

0

Adjust the button clamp jaw lever holder

holesin the button.

(5) The work pressing force is too high or too

0

Adjust the work pressing force properly.

low.

I

3.

The first stitch The thread pull-off lever does not work

trails relatively properly.

long thread from

the right side of

-

4. Thread trimming

failure in the state

of stop-motion.

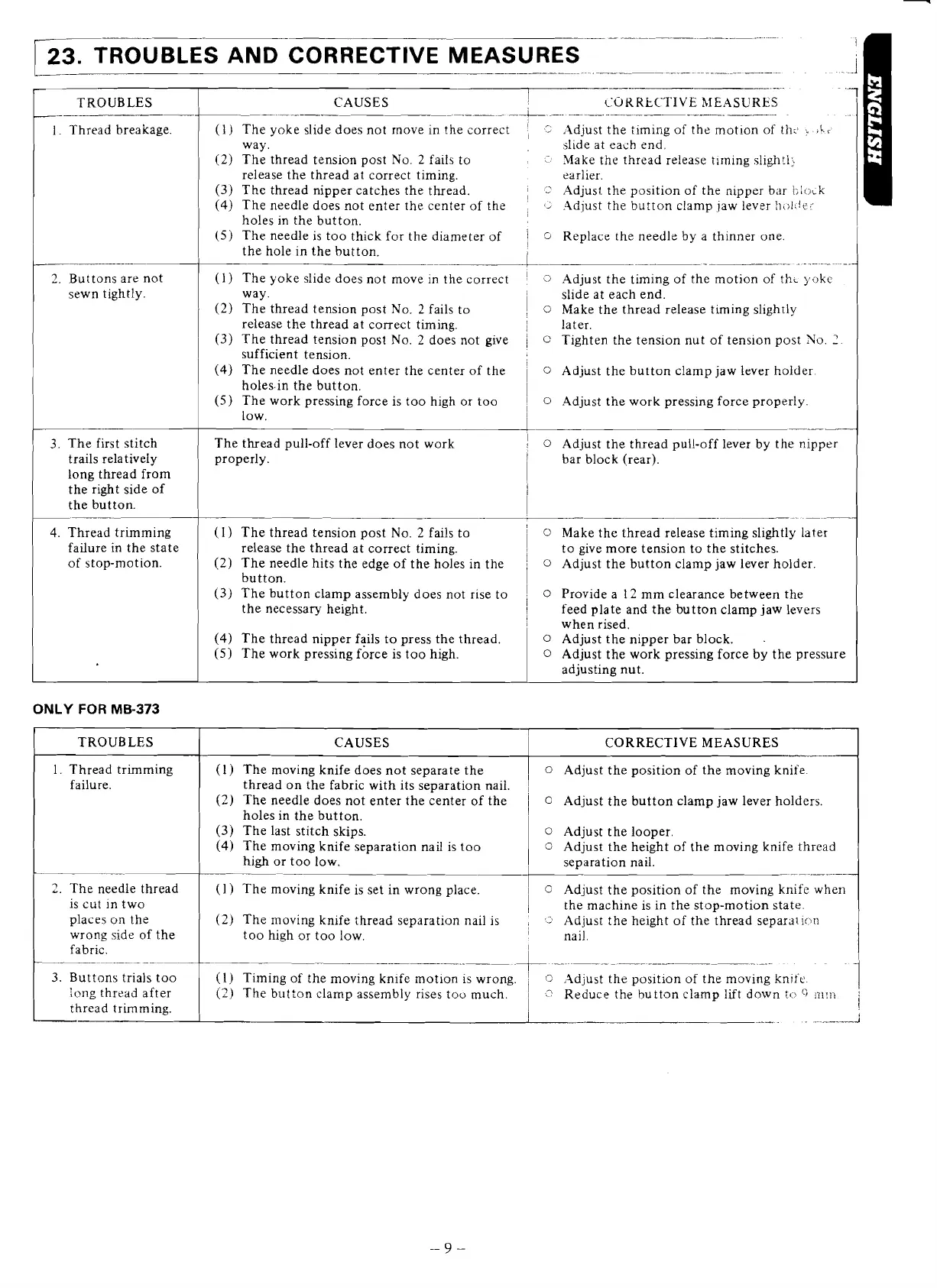

ONLY

FOR

MB-373

(1) The thread tension post No. 2 fails to

release the thread at correct timing.

(2) The needle hits the edge of the holes in the

button.

(3)

The button clamp assembly does not rise to

the necessary height.

(4) The thread nipper fails to press the thread.

(5) The work pressing force is too high.

0

Adjust the thread pull-off lever by the nipper

bar block (rear).

~~-~p~.--~

-

--

I

0

Make the thread release timing slightly later

to give more tension to the stitches.

0

Adjust the button clamp jaw lever holder.

0

Provide a

12

mm clearance between the

feed plate and the button clamp jaw levers

when rised.

0

Adjust the nipper bar block.

.

0

Adjust the work pressing force by the pressure

adjusting nut.

[

TROUBLES

1

1. Thread trimming

failure.

2.

The needle thread

is cut

In two

places on the

wrong side of the

fabric.

-

-

-

--

CAUSES

(1) The moving knife does not separate the

thread on the fabric with its separation nail.

(2) The needle does not enter the center of the

holes in the button.

(3)

The last stitch skips.

(4) The moving knife separation nail is too

high or too low.

-

-

CORRECTIVE MEASURES

0

Adjust the position of the moving knife.

0

Adjust the button clamp jaw lever holders.

0

Adjust the looper.

Adjust the height of the moving knife thread

separation nail.

(I)

The moving knife is set in wrong place.

1

0

Adjust the position of the moving knife when

1

the machine is in the stop-motion state.

(2) The moving knife thread separation nail is

,.,

Adjust the height of the thread separa1~wn

too high or too low.

I

nail.

3. Buttons trials too

Icng

thread after

thread trimming.

L

(1)

Timing of the moving knife motion is wrong.

1

(3

Adjust the position of the moving knife.

I

(2)

The button clamp assembly rises too much.

/

-?

Reduce the button clamp lift down

tr:>

%ill:i?

1

...

-.

. .

---J

!

Loading...

Loading...