*

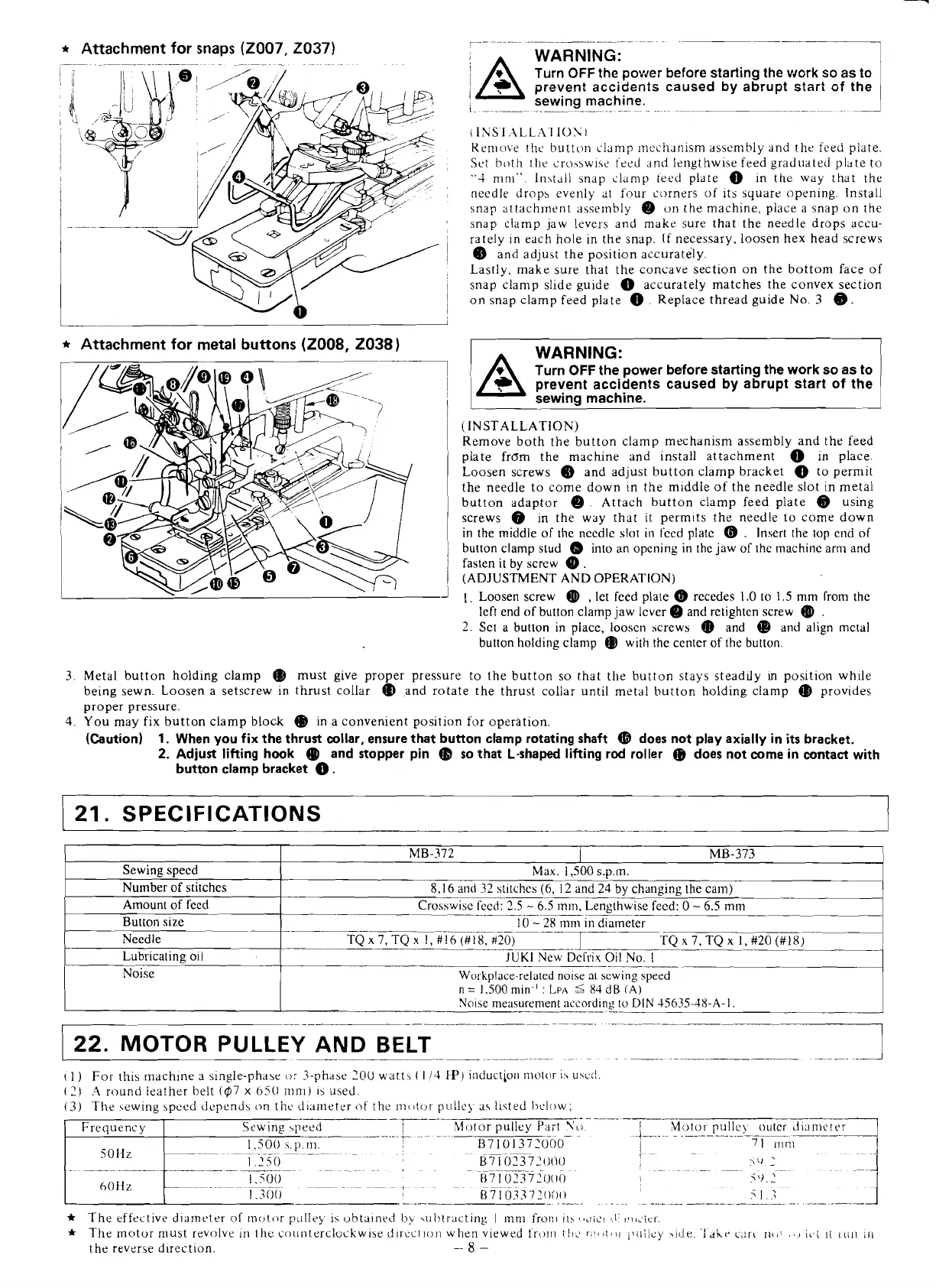

Attachment

for

snaps

(2007,2037)

-

- -

-

--

-

--

--

-

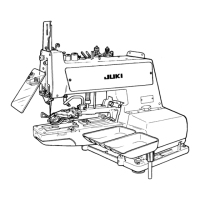

*

Attachment

for

metal

buttons (2008, 2038)

---

~ ~

.

.

-

--

A

WARNING:

Turn

OFF

the power before starting the work so as

to

I

prevent accidents caused by abrupt

start

of

the

sewing machine.

1

-.-

-

2

I

INS1

.ALL?-\I

ION!

Ken~c~ve rh~ button clamp iricciianism assembly and the feed plate.

Set both

the croswlse teed and lengthwise feed graduated plate to

'.4

ninl". Ir~stdli snap clamp teed plate

@

in the way that the

needle drops evenly

dt

four corners of its square opening. Install

snap attachment assernbly

@

on the machine, place a snap on the

snap clamp jaw levers and make sure that the needle drops accu-

rately in each hole in the snap.

If

necessary. loosen hex head screws

@

and adjust the position accurately.

Lastly, make sure that the concave section on the bottom face of

snap clamp slide guide

0

accurately matches the convex section

on snap clamp feed plate

@

.

Replace thread guide No.

3

@.

WARNING:

Turn

OFF

the power before starting the work so as to

prevent accidents caused by abrupt start of the

in.

sewing machine.

1

(INSTALLATION)

Remove both the button clamp mechanism assembly and the feed

plate

frdm the macfune and install attachment in place.

Loosen screws

@

and adjust button clamp bracket

0

to permit

the needle to come down in the middle of the needle slot in metal

button adaptor

@

.

Attach button clamp feed plate

@

using

screws

@

in the way that it permits the needle to come down

in the middle of the nccdlc slot in

fced plate

@

.

Insert the top cnd of

button clamp stud

@

into an opening in the jaw of the machine arm and

fasten it by screw

@

.

(ADJUSTMENT AND OPERATION)

1.

Loosen screw

@

,

let feed plate

@

recedes 1.0 to

1.5

mm from the

left end of button clamp jaw

lever

@

and retighten screw

@

.

2.

Set a button in place, loosen screws

Q)

and

@

and align metal

button holding

clamp

@

with the center of the button.

3.

Metal button holding clamp

@

must give proper pressure to the button so that the button stays steadlly

in

position while

being sewn. Loosen a setscrew in thrust collar

(b

and rotate the thrust collar until metal button holding clamp

@

provides

proper pressure.

4.

You may fix button clamp block

@

in a convenient position for operation.

(Caution)

1.

When you fix the thrust collar, ensure that button clamp rotating shaft

@

does not play axially in its bracket.

2.

Adjust lifting hook

@

and stopper pin

@

so that L-shaped lifting rod roller

(B

does not come in contact with

button clamp bracket

0.

/

21.

SPECIFICATIONS

p~

-

-

--

Needle

TQx7,TQx 1,#16(#18,#2O)

~___~-.pp

TQ

x 7 TQ

x

I,

#20(#1~)-

Lubricating oil

..

.

JUKl

~

New Deirix

Oil

No.

1

~

Sewing speed

Number of stitches

Amount of

feed

I

No~se

I

Workplace-relared noise

at

sewing speed

I

I--

n

=

1.500 mln

'

LPA

I

8-1

d~

(A)

'

NOI~ measurement

according

to DIN 45635-48-A-

I

-

-

-

Button size

10

-

28

mm in diameter

122.

MOTOR PULLEY AND BELT

I

MB-372

I

I)

For

this rnachlne

3

single-phase

or

3-phase 2OU watts

(

I

!4

W)

inductjun motor

i:,

u\c:~.

(2)

.4

round leather belt ($7

x

bSC1

rl~ni)

15

used.

(3)

The \ewing speed depends on lht. d~airleter

nf

thc lTl<lt(~r puiiey as listed Ijelow;

-

-.

T--------.

.

-

-.

-

--

-

1

Motor p~llcy

Pail

Yo

~.--

~..

~

..

.

.-

.I--.

I

..

Motor

-

.

puIle\.

.-:

outer

~11;-

07

101 372TJG0-

1

7

I

inn1

I

-.

-

~~-

~

.

~

~~~

r

-

.A

1.250

B7

102372!)00

><>

:

I

8,16 and 32 stitches

(6,

I2 and

24

by

changing the cam)

Crosswise fecd:

2.5

-

6.5

mln,

~englhwise feed:

0

-

6.5

mm

-

.-

.

-.

.

--

MB-373

L

I

..

...-.

..

-1

*

The effective d~arneter

of

noto or

pi:llt.y is ohta~nrd

by

yul~tracting

I

rnnt fro111

II\*~LI~C!

:.ii~~ic~icr.

The motor nlust revolve in the co~interclockwise dlrccr1o11 when viewed fro111

;!I:

r;l<,t,i!

ii!iilc.y

yide.

'idi\t-

c,irt

IIC,~

.,,

i,-i

I[

iiili

iri

the reverse direction.

-8-

Max. 1,500 s.p.ln.

-

Loading...

Loading...