1

9.

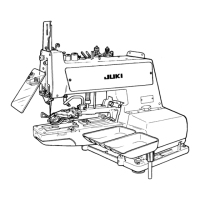

NEEDLE-TO-LOOPER RELATION

i

I

WARNING:

I

Turn OFF !he power before starting the work so as to prevent accidents caused

by

abrupt start of the sewing machine.

i

*

Adjust the needle-to-looper relation as follows;

1. Depress the pedal fully forward, turn the needle driving pulley in the normal sewing direction to bring down the needle

bar

to

the lowest point of its stroke

andloosen screw

.

(Adjusting the needle bar height)

2.

Adjust the height of the needle bar using top two lines engraved on the needle bar for the

TQx

1

needle and using the bottom two

lines for the

TQx7

needle. Align the upper line

Q

with the bottom end face of needle bar bushing (lower)

8)

and tighten screw

in the way that needle clamp screw

rests in the slot of the needle bar bushing (lower)

6)

.

(Looper position),

3.

Loosen screws

@

and turn by hand the needle driving pulley until lower line

(D

of two lines aligns with the bottom end face

of needle bar bushing (lower)

6)

.

4.

By keeping the machine in this state, align looper blade

(b

with the center of the needle and tighten screws

@

.

5.

Loosen screw

8

and provide a 0.05 to 0.1 mm clearance between the looper and the needle. Tighten screw

8

.

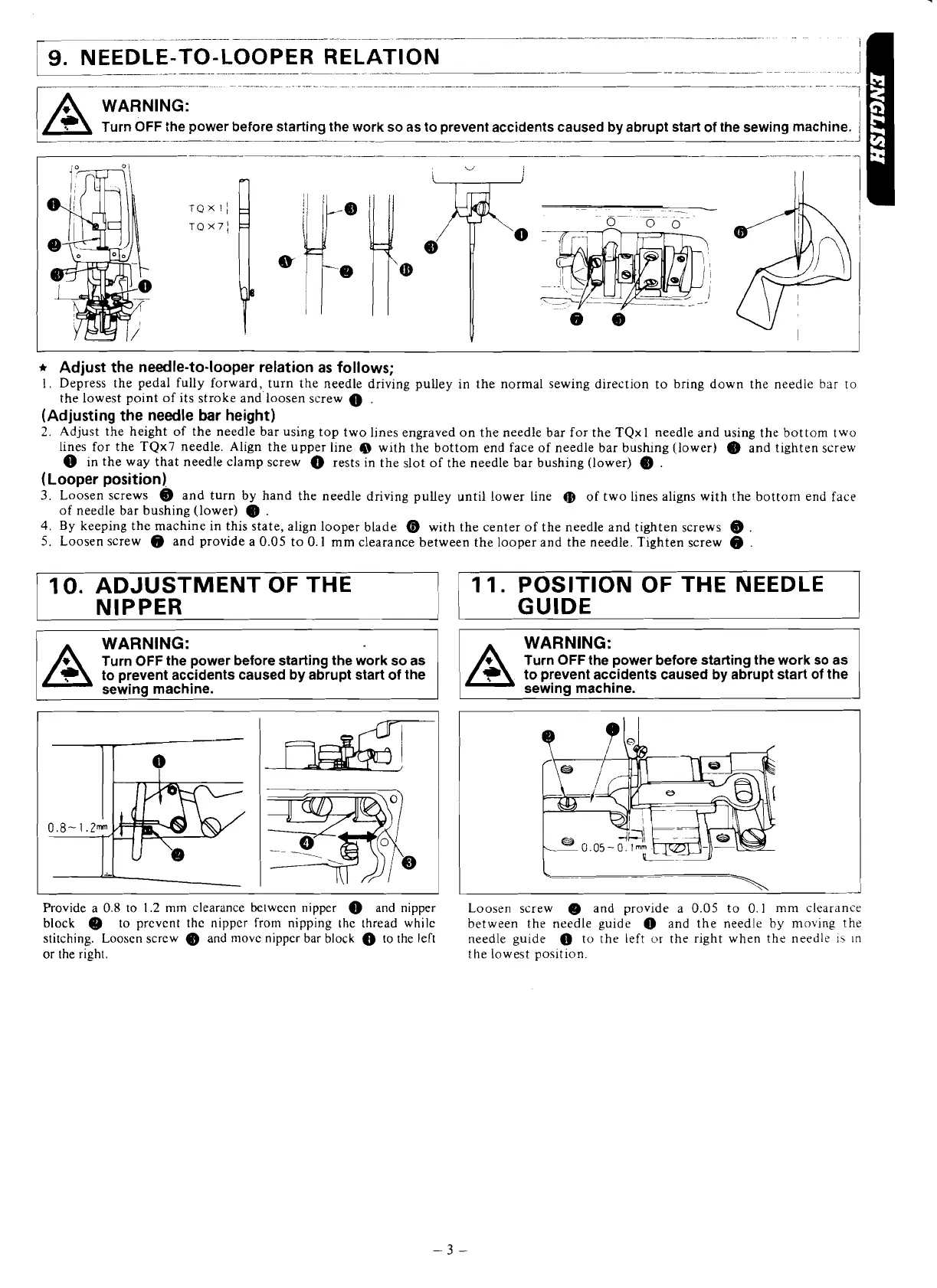

Provide a 0.8 to

1.2

mm clearance between nipper and nipper Loosen screw

@

and provide a 0.05 to 0.1

mm

clearance

block

@

to prevent the nipper from nipping the thread while between the needle guide

0

and the needle by moving the

stitching. Loosen screw

6)

and movc nipper bar block to the lert

needle guide

0

to the left or the right when the needle

15

in

or the right.

the lowest position.

10.

ADJUSTMENT OF THE

!

NIPPER

Turn OFF the power before starting the work so as

to prevent accidents caused by abrupt start of the

sewing machine.

11.

POSITION OF THE NEEDLE

GUIDE

Turn

OFF

the power before starting the work so

as

to prevent accidents caused by abrupt start of the

sewing machine.