– 9 –

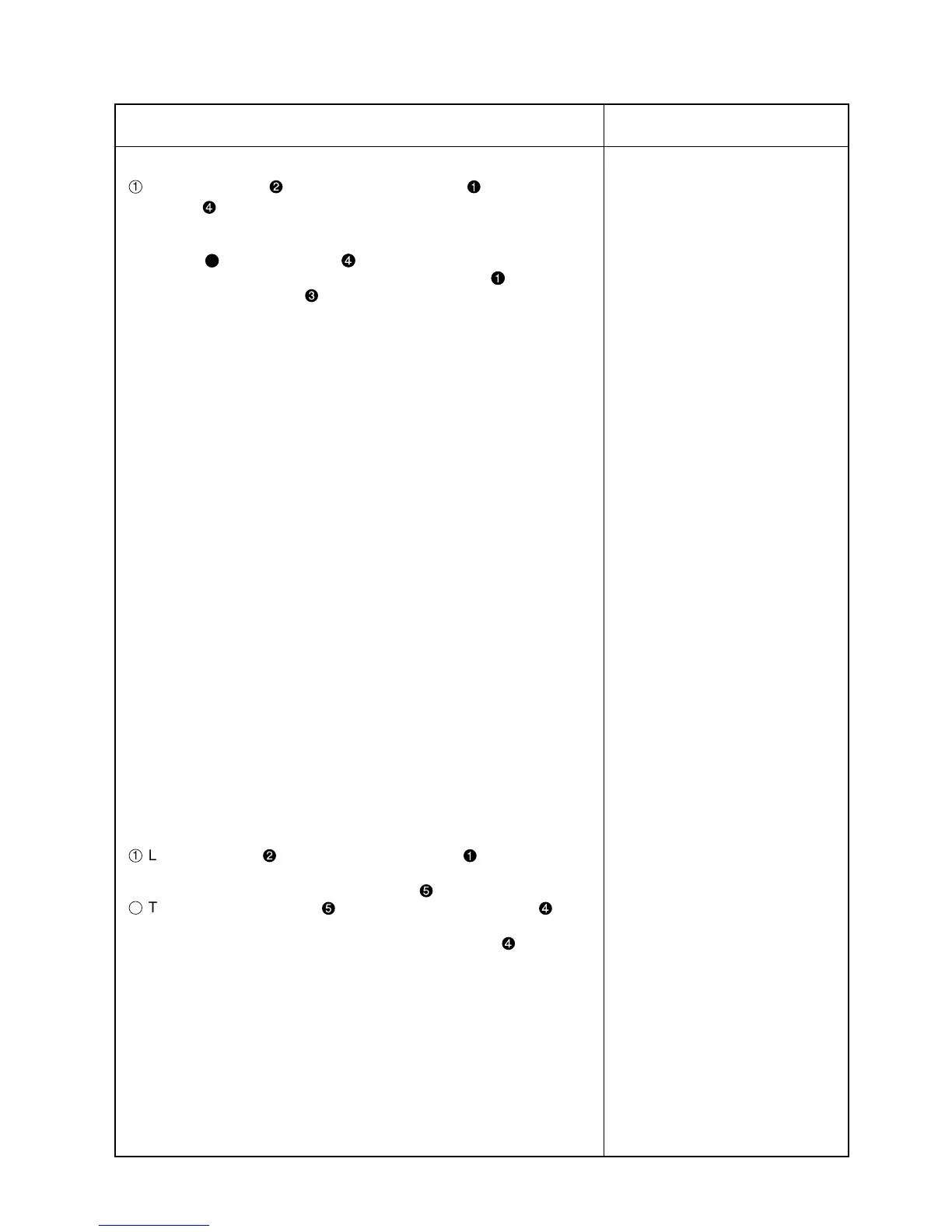

o Excessive return of the lower

looper tends to cause stitch

skipping when filament thread is

used.

o Insufficient return of the lower

lopper tends to cause needle

thread stitch skipping when spun

thread is used.

o Excessive clearance will often

cause needle thread stitch

skipping.

o Insufficient clearance will cause

needle breakage due to the con-

tact of the looper with the needle,

or produce scratches on the

blade point of the looper, lead-

ing to needle thread breakage or

other troubles.

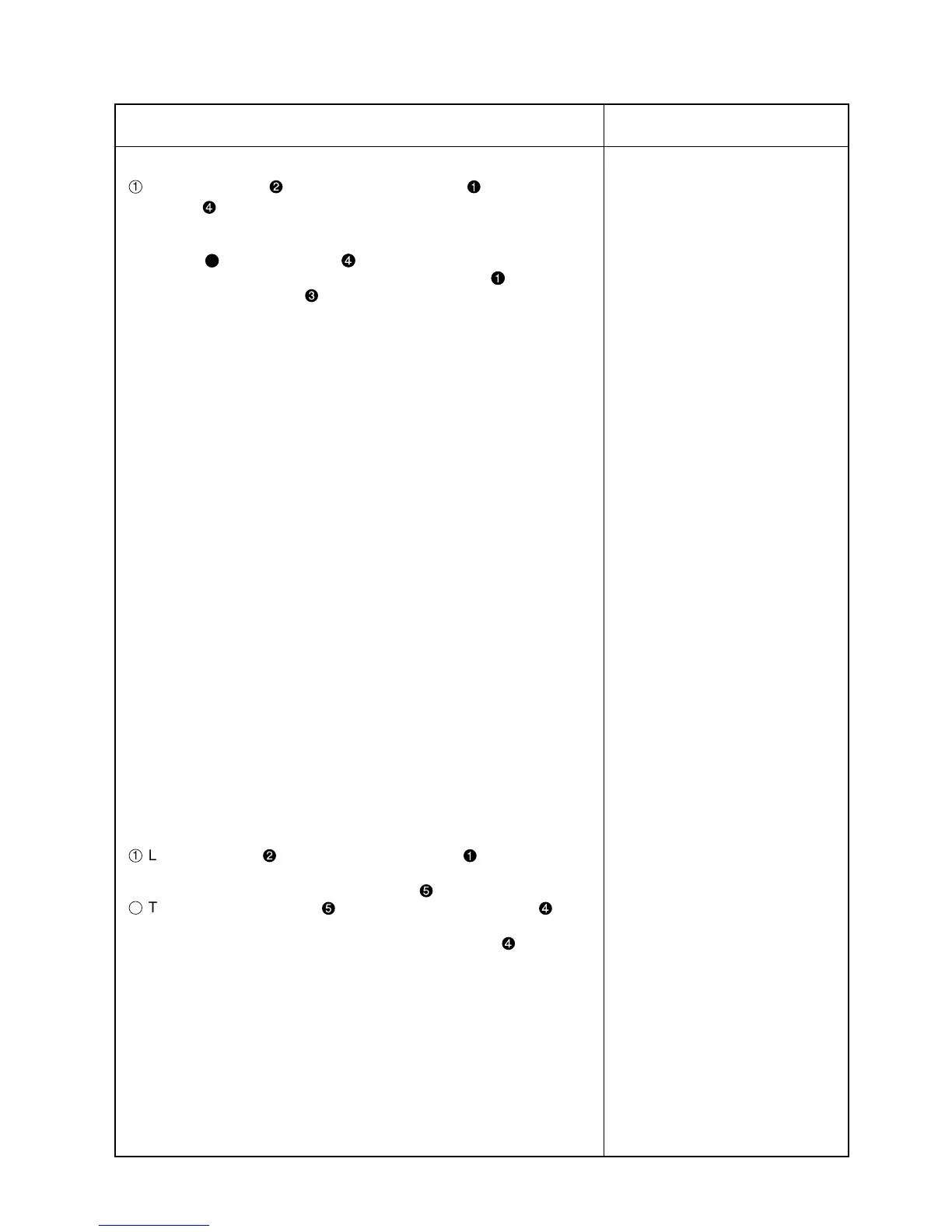

1) Returning amount of the lower looper

1

Loosen setscrew of lower looper support arm and adjust lower

looper to make adjustment of the returning amount.

(Referential information)

1. Radius

K

of lower looper will be 66.9 mm when the lower

looper is inserted into lower looper support arm until it con-

tacts with stopper pin and then is fixed.

2. The rocking angle of the lower looper will be 26°.

2) Clearance between the lower looper and the needle

1

Loosen setscrew of lower looper support arm to the extent that

it is temporarily tightened. Then finely adjust the longitudinal position

of the looper using fine adjustment screw .

2

Turn fine adjustment screw clockwise to move lower looper away

from the needle.

Turn the screw counterclockwise to move lower looper closer to it.

Adjustment Procedure Results of Improper Adjustment

Loading...

Loading...