– 1 –

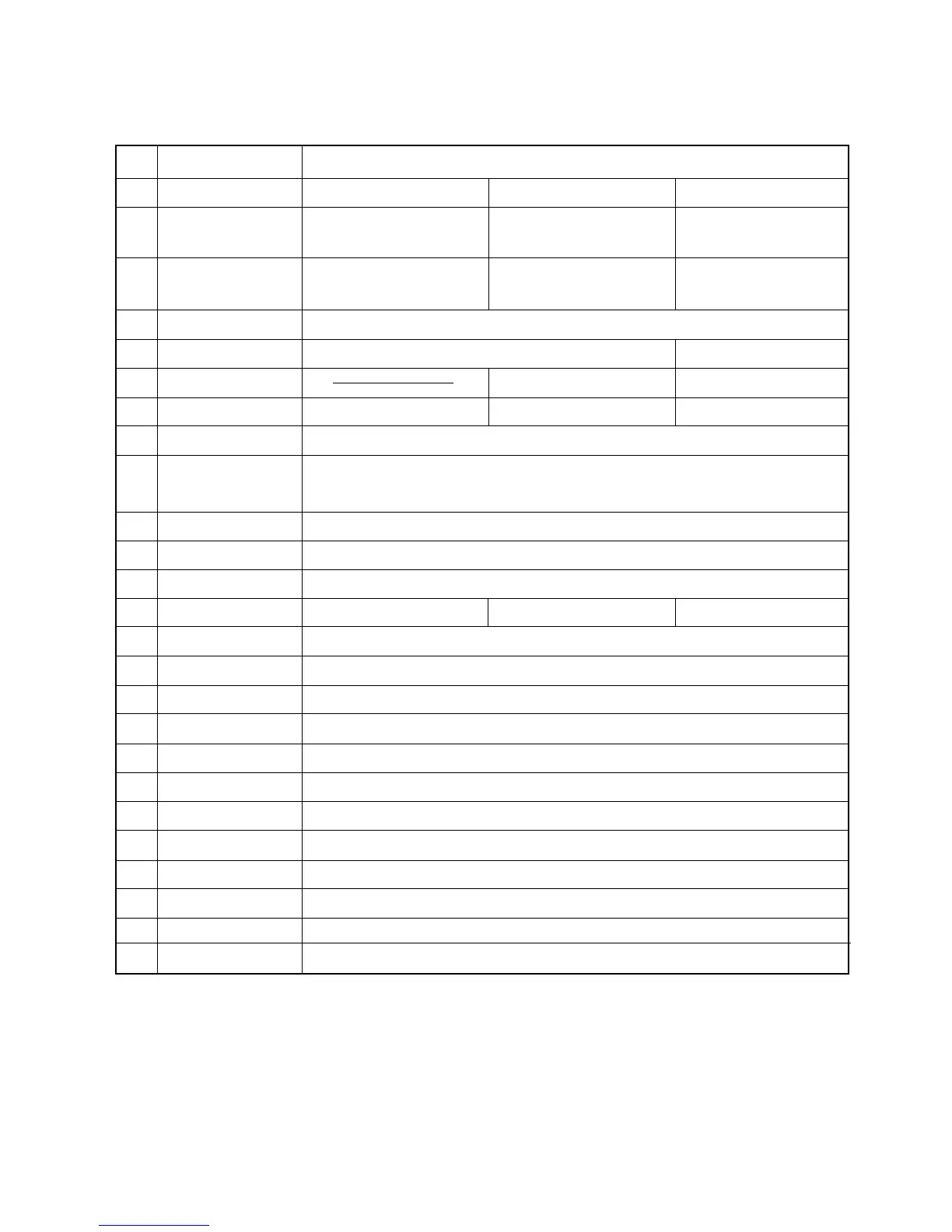

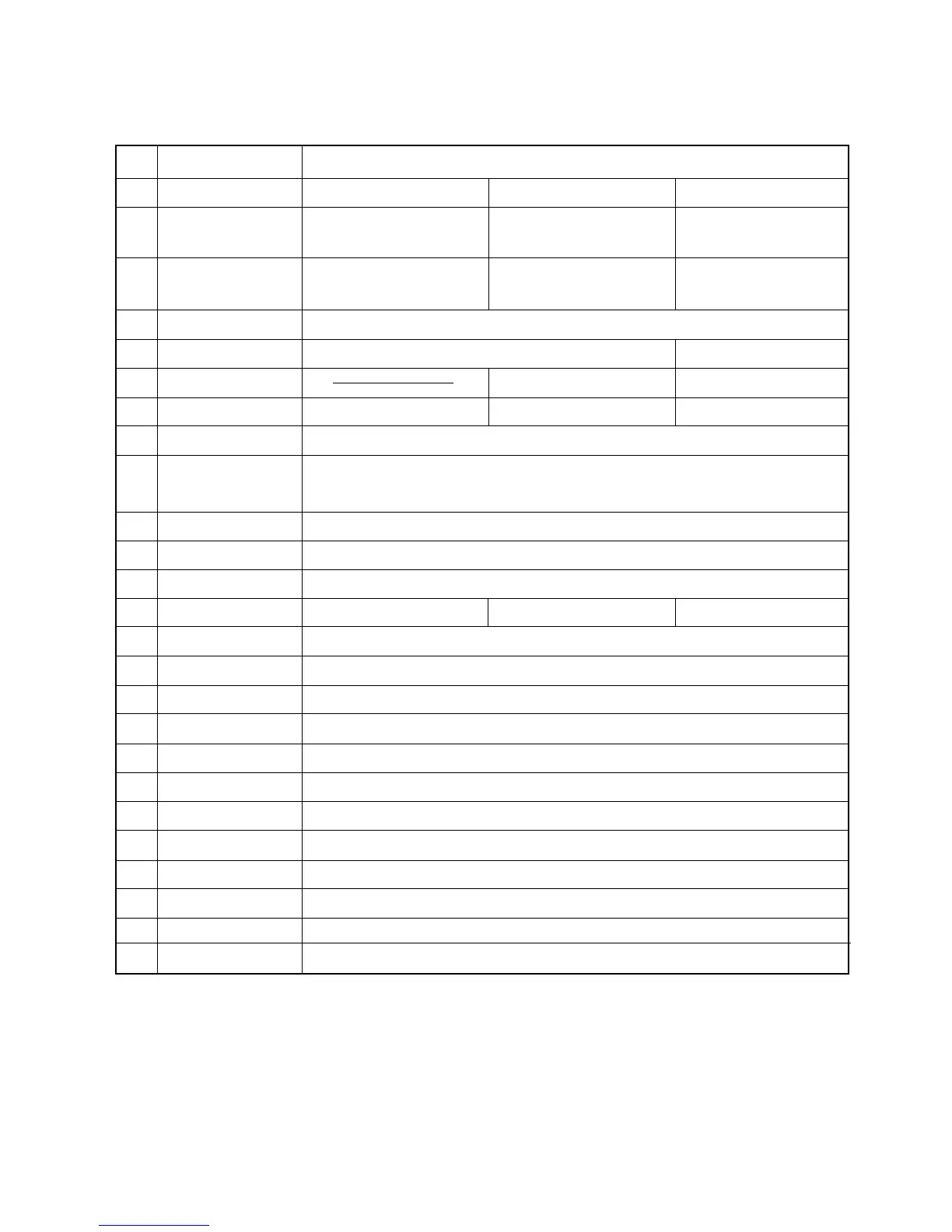

1. SPECIFICATIONS

(1) MO-6700D SERIES

No. Item Specifications

1 Model MO-6704D MO-6714D MO-6716D

2 Description 1-needle Overlock 2-needle Overlock 2-needle Safety stitch

machine machine machine

3 Stitch type F. S. T. JIS E13 JIS E24 JIS E13+D12

(USA standard : 504) (USA standard : 514) (USA standard : 516)

4 Sewing speed 6000rpm

5 Stitch length 0.8 to 4mm 1.5 to 4mm

6Needle gauge 2.0, 3.2mm 3.2, 4.8mm

7Overedging width 1.6, 3.2, 4, 4.8mm 2.0, 3.2, 4mm 3.2, 4, 4.8, 6.4mm

8 Differential feed ratio Gathering 1 : 2 (Max.1 : 4), Stretching 1 : 0.7 (Max.1 : 0.6)

9 Needle bar stroke 24.5 mm (30P for light to medium-weight materials),

25.5 mm (40H for medium to heavy-weight materials)

10 Needle tilt angle 20°

11

Needle bar mechanism

Upper and lower needle bar bushing type

12 Needle ORGAN DC X 27 (Standard) (DC X 1 can be used as well.)

13 Presser lifting amount 7.0mm 6.5mm 7.0mm

14 Presser foot pressure 49N (5kg)

15

Stitch adjusting method

By pushbutton

16 Upper knife Flat knife

17

Differential feed adjustment

By lever with micro adjustment mechanism

18 Weight 28kg

19 Lubrication Automatic geared lubrication system and grease charge

20 Lubricating oil JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Product No.: MML018900CA

21 Grease Exclusive grease (Part No. 23640204)

22 Needle cooler Optional

23 Needle thread cooler Optional

24

Micro presser lifting device

Provided as standard

25 Motor 2P 400W

*1. Grease should be supplied to the needle bar system and upper looper system.

Loading...

Loading...