– 4 –

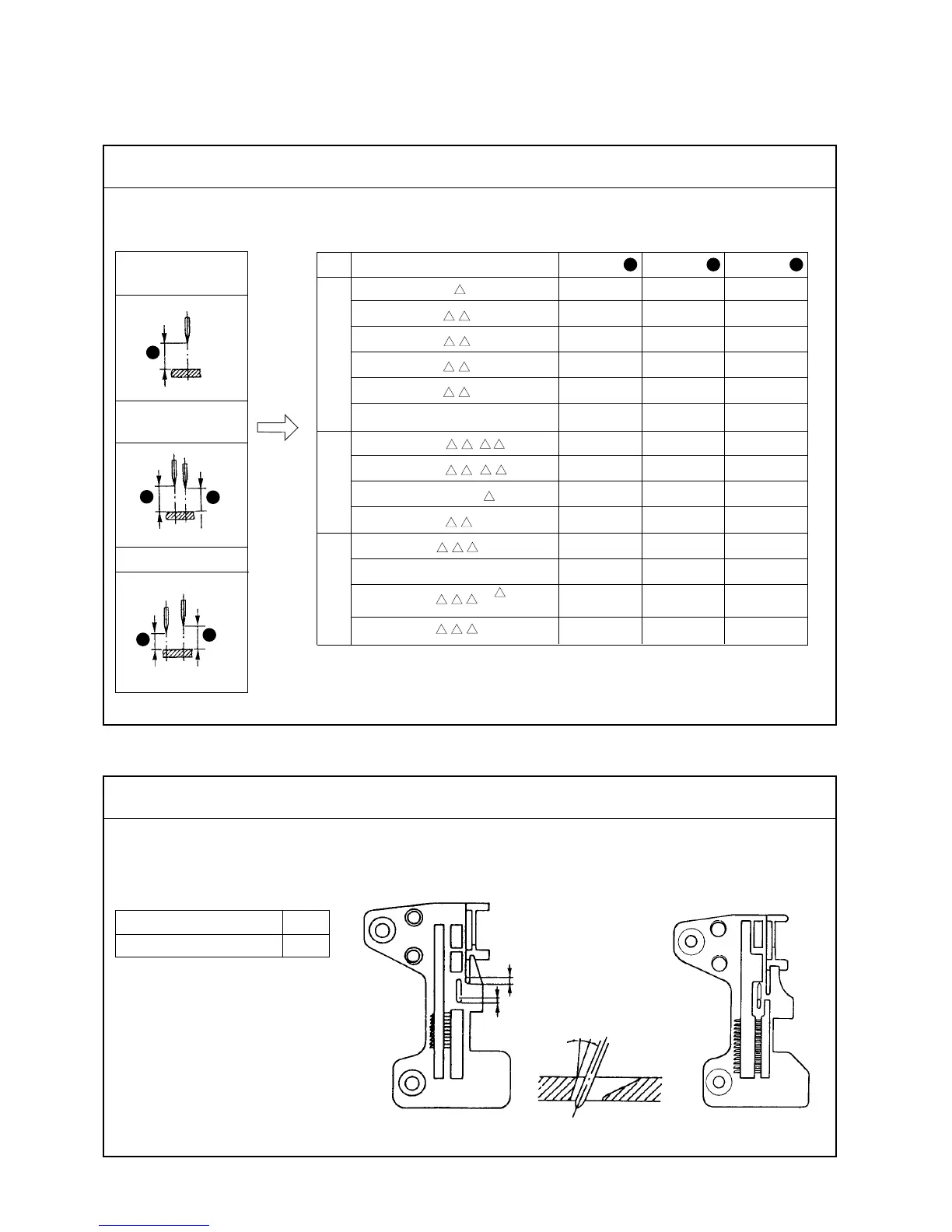

Model

Dimension

A

Dimension

B

Dimension

C

MO-6704D-0A -150 10.5 — —

MO-6705D-0 -210 10.5 — —

MO-6704D-0 -300 10.5 — —

MO-6704D-0 -307 10.5 — —

MO-6704D-0 -40H 11.3 — —

MO-6704D-0F6-50H 11.3 — —

MO-6714D-B - 7 10.5 9.1 —

MO-6714D-B - H 11.3 9.9 —

MO-6712D-DF6-50 11.0 9.4 —

MO-6714D-B -30P 10.5 9.1 —

MO-6716D- -300 10.5 — 9.8

MO-6716D-FF6-307 10.5 — 9.8

MO-6716D- - 11.3 — 10.6

MO-6716D- -30P 10.5 — 9.8

A

B

10

°

6704D

6705D

6712D

6714D

6716D

When the needle(s) is in the highest position, the needle height from the throat plate surface should be as

shown below.

3. STANDARD ADJUSTMENT

(1) Adjusting the needle height

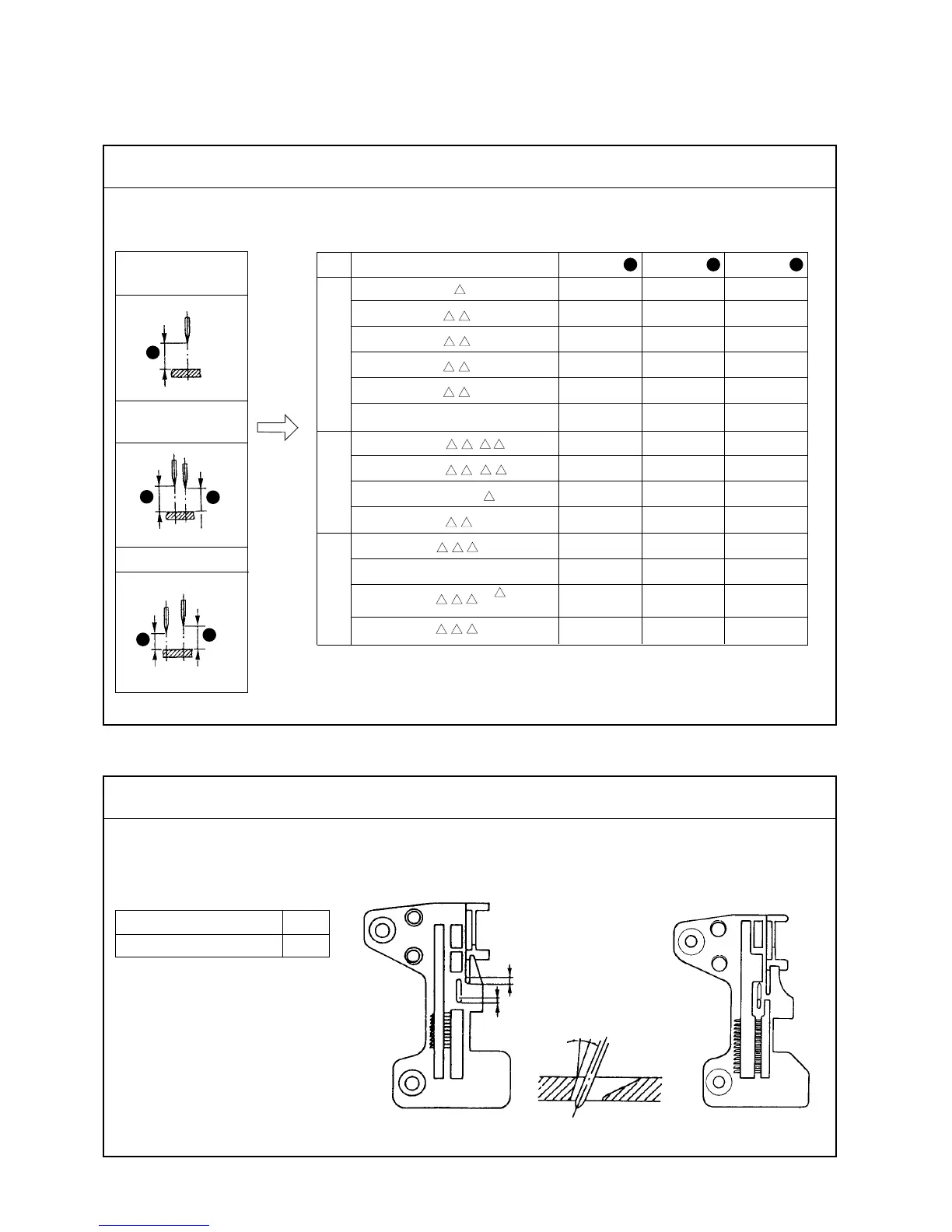

The needle entry point should be such that the distances listed below are provided between the needle slot

edge of the throat plate and the center of needle.

(2) Positioning the throat plate

(Unit : mm)

The adjustment of needle height for the 2-needle overlock machine should be

made in reference to the left needle.

(Unit : mm)

Overlock side A 1.3

Double-chainstitch side B 1.0

For 30P

(Safety stitch machine)

4 H

50H

A

A

B

C

A

Standard Adjustment

Standard Adjustment

1-needle overlock

machine

2-needle overlock

machine

Safety stitch

machine

Loading...

Loading...