– 19 –

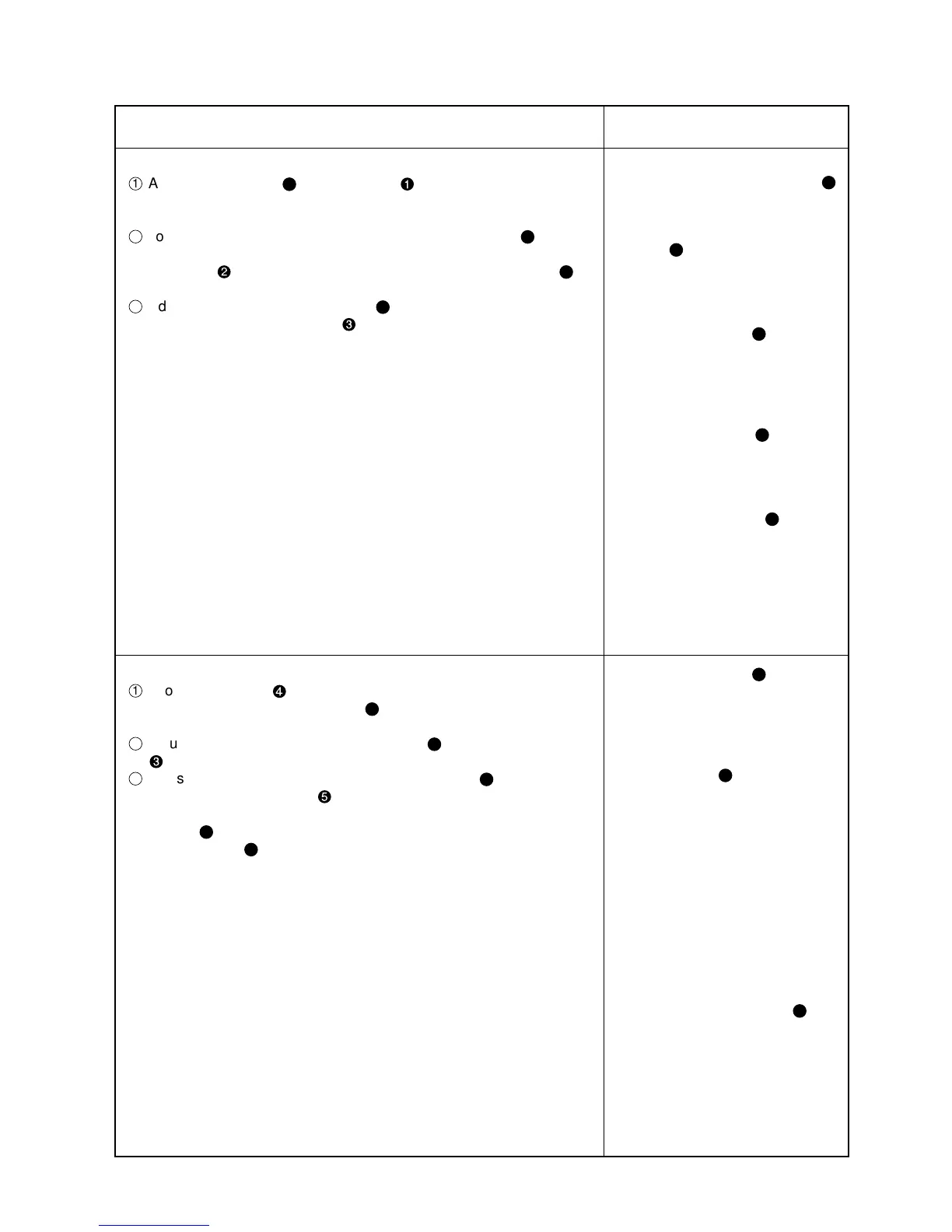

1) For 1-needle or 2-needle overlock machine

1

Adjust needle guard

A

with setscrews in the needle guard so that

it lightly comes in contact with the needle when the blade point of the

lower looper reaches the needle center.

2

To adjust the clearance provided between needle guard

B

and the

needle when the needle bar is at the lowest point of its stroke, loosen

setscrews in the needle guard support and turn needle guard

B

to

adjust the clearance to 0.1 mm.

3

Adjust the height of needle guard

B

to 1 mm from the throat plate

bottom surface with setscrew in the needle guard.

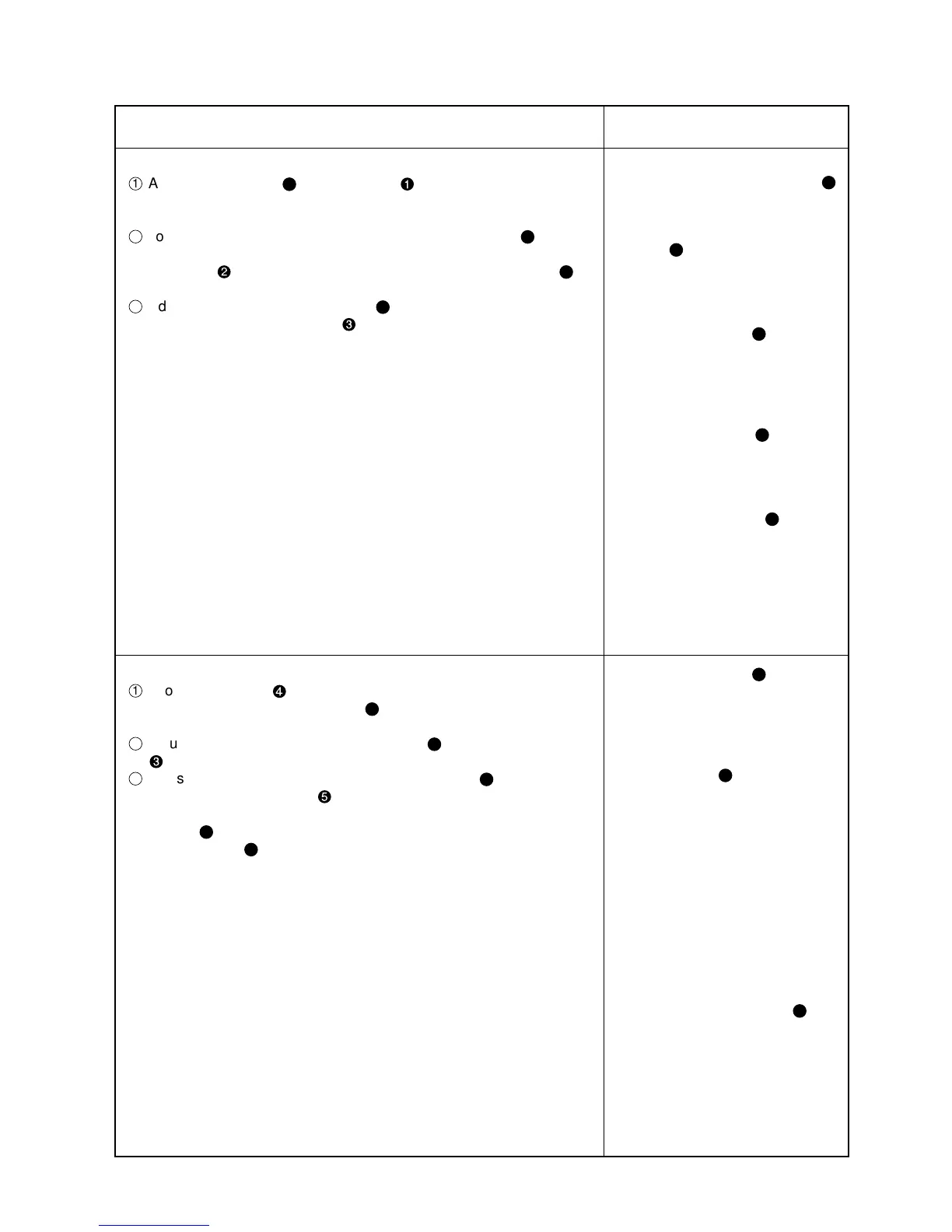

2) For safety stitch machine

1

Loosen setscrews in the needle guard, and adjust the clearance

provided between needle guard

C

and the needle so that it lightly

comes in contact with the needle.

2

Adjust the installing height of needle guard

C

to 5 mm with setscrew

in the needle guard.

3

Adjust the clearance provided between needle guard

D

and the needle

to 0.1 mm with setscrews .

(Caution) Check again the clearance provided between needle guard

B

and the needle after adjusting the height of needle

guard

C

.

o Excessively close contact

between the needle guard

A

and the needles will lead to

needle bend or stitch skipping.

oA clearance left between the needle

guard

A

and the needles will cause

the looper blade point to come in

contact with the needles, leading to

needle or blade point breakage, or

other troubles.

o If the needle guard

B

is too high,

thread loops will be damaged

with resultant stitch skipping.

Also, double chain loops will be

affected, causing double chain

stitch skipping.

o If the needle guard

B

is too low,

the needle cooling felt will be low-

ered, resulting in deteriorated effect

of the cooling and needle guard.

oExcessive clearance between

the needle guard

B

and the

needle will cause stitch skipping

due to needle shake. On the con-

trary, insufficient clearance will

cause the needle guards to catch

the needles between them, lead-

ing to wear on the needle guards

and scratches on the needles.

o If the needle guard

C

is too high,

the needle thread loops will be

damaged, and stitch skipping

occurs. If it is too low, the needle

points will be crushed.

o If the clearance between the

needle guard

C

and the needles

is too large, the double chain

looper blade point will come in

contact with the needles, causing

the breakage of the needles,

causing the breakage of the

needles or looper blade point.

No clearance left between them

will cause them to come in exces-

sively close contact with each other,

and bend of needle, wear on the

needle guard and scratches on the

needles will occur.

o Excessive clearance left be-

tween the needle guard

D

and

the needles will cause stitch skip-

ping due to needle shake, and

insufficient clearance will cause

the needle guards to catch the

needles between them, leading

to wear on the needle guards

and scratches on the needles.

Adjustment Procedure Results of Improper Adjustment

Loading...

Loading...