– 27 –

87

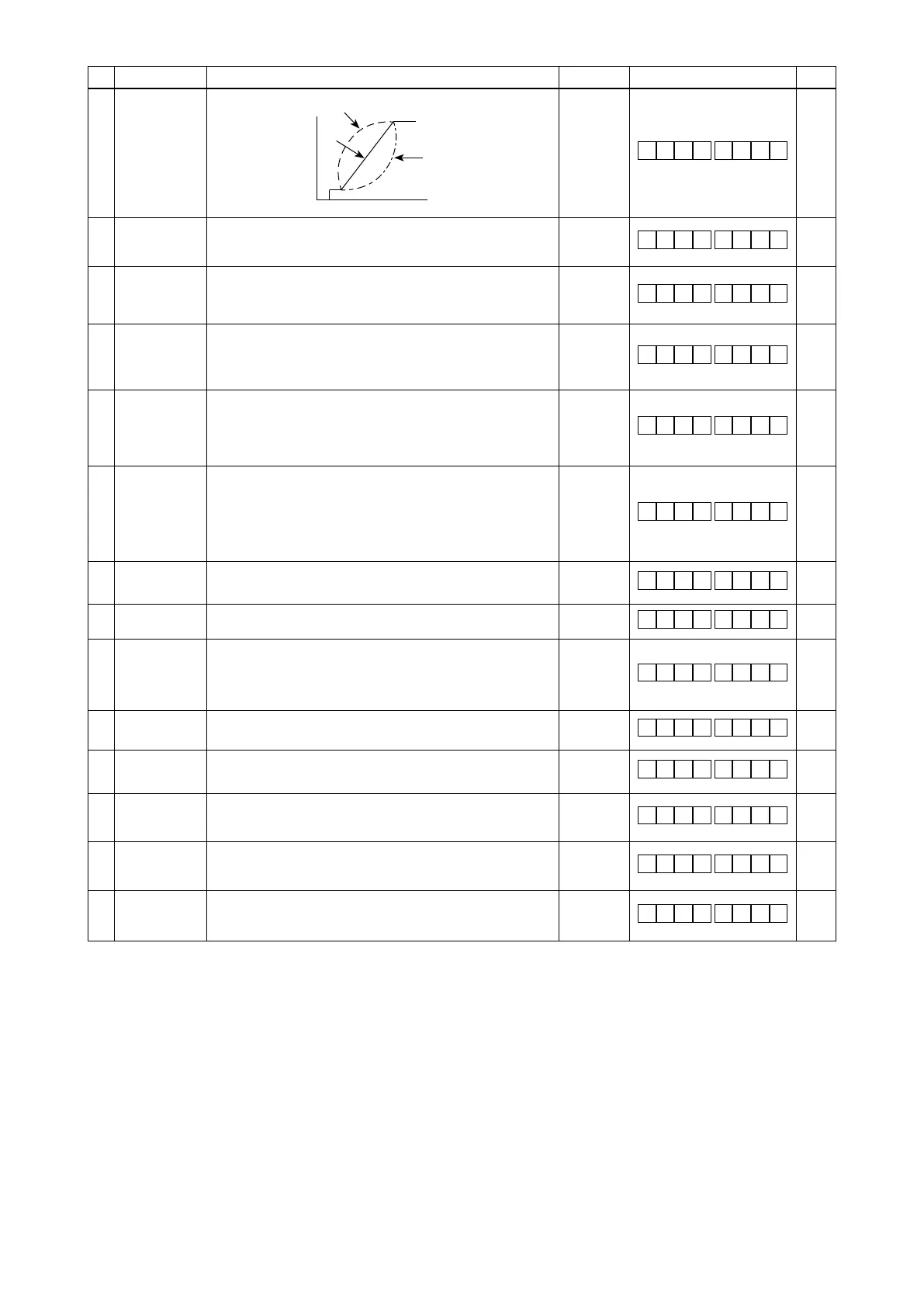

Function of pedal

curve selection

Pedal curve is selected. (Improving pedal inching operation)

Number of rotations

Pedal stroke

2

0

1

0/1/2

8 7

0

36

90

Initial motion up

stop function

Automatic UP stop function is set immediately after turning ON the

power.

0 : off

1 : on

0/1

9 0

1

37

91

Function of prohibiting

compensation

operation after turning

handwheel by hand

It is effective in combination with the machine head provided

with tension release function.

0 : Tension release function is ineffective.

1 : Tension release function is effective.

0/1

9 1

1

92

Function of

reducing speed

of reverse feed

stitching at the

start of sewing

Function to reduce speed at the time of completion of reverse

feed stitching at the start of sewing.

0 : Speed is not reduced.

1 : Speed is reduced.

0/1

9 2

0

36

93

Function added to

needle up/down

compensating

switch

Operation of needle up/down compensating switch is changed

after turning ON the power or thread trimming.

0 : Normal (needle up/down compensating stitching only)

1 : One stitch compensating stitching is performed only when

aforementioned changeover is made. (Upper stop / upper

stop)

0/1

9 3

0

37

94

Continuous +

One-shot nonstop

function

The function that does not stop the sewing machine by com-

bining continuous stitching with one-shot stitching using the

program sewing function which is available in the IP operation

panel.

0 : Normal (The sewing machine stops when a step is com-

pleted.)

1 : The sewing machine does not stop when a step is com-

pleted and proceeds to next step.

0/1

9 4

0

37

95

Head selection

function

Machine head to be used is selected.

(When the machine head is changed, each setting item is changed

to the initial value of the machine head.)

9 5

d L b M

96

Max. number of

rotation setting

Max. number of rotation of the sewing machine head can be set.

(The MAX value differs by machine head.)

150 to MAX

(sti/min)

9 6

4 0 0 0

37

100

Number of

stitches sewn

before thread

clamp works at

the beginning of

sewing

Sets the number of stitches to be sewn at the beginning of sew-

ing before the thread clamp solenoid (CN36-7) starts operating

0: Thread clamp solenoid does not operate.

1-9: The number of stitches to be sewn before the thread clamp

solenoid operates

0-9

(stitches)

1 0 0

0

103

Needle cooler

output OFF

delay time

Delay time from the stop of sewing machine to the output OFF is

specied using the needle cooler output function.

100 to

2000 (ms)

1 0 3

5 0 0

120

Main shaft

reference angle

compensation

Main shaft reference angle is compensated.

–60 to 60

1 2 0

– 2 3

37

121

Up position

starting angle

compensation

Angle to detect UP position starting is compensated.

–15 to 15

1 2 1

5

37

122

DOWN position

starting angle

compensation

Angle to detect DOWN position starting is compensated.

–15 to 15

1 2 2

0

37

124

Setting of

energy-saving

function during

standby

Setting to reduce the power consumption while the sewing ma-

chine is in standby state

0: Energy-saving mode is ineffective

1: Energy-saving mode is effective

0/1

1 2 4

0

37

No.

Item Description

Setting range

Indication of function setting

Ref. page

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

Loading...

Loading...