TP-6198 3/15 25Section 3 Troubleshooting

Section 3 Troubleshooting

3.1 Introduction

Corrective action and testing in many cases requires

knowledge of electrical systems and electronic circuits.

Have an authorized distributor/dealer or trained service

technician perform testing and service.

Refer to the engine service manual for engine service

information.

The first step in troubleshooting the generator set

controls is to verify that the controller is correctly

configured for the generator set. The generator set

installation manual explains how to check and change

the controller configuration.

If the troubleshooting procedures in this section identify

a bad part, refer to the parts catalog for replacement part

numbers. See the List of Related Materials in the

Introduction for the literature part numbers.

3.2 Initial Checks

When troubleshooting, always check for simple

problems first. Check for the following common

problems before replacing parts:

D Loose connections or damaged wiring.

D Dead battery.

D Fault shutdown. Check for a fault code on the

ADC 2100 display. Section 4.5 describes the

warning and shutdown fault codes.

D Blown fuses. Fuses protect the controller, SCR

module, and relay interface board. Always check and

replace the fuses before replacing other components.

D Incorrect controller settings. Always check the

controller configuration settings before replacing the

controller. Section 4.9 explains how to check and

change the controller settings.

D Inadequate fuel supply. Check for damaged

primary or secondary fuel regulators, loose

connections to the fuel solenoid valve, a damaged or

closed fuel shutoff valve, an empty LP fuel tank, or

other problems with the fuel supply. Check the fuel

supply pressure to the generator set. See

Section 5.11, Fuel Systems.

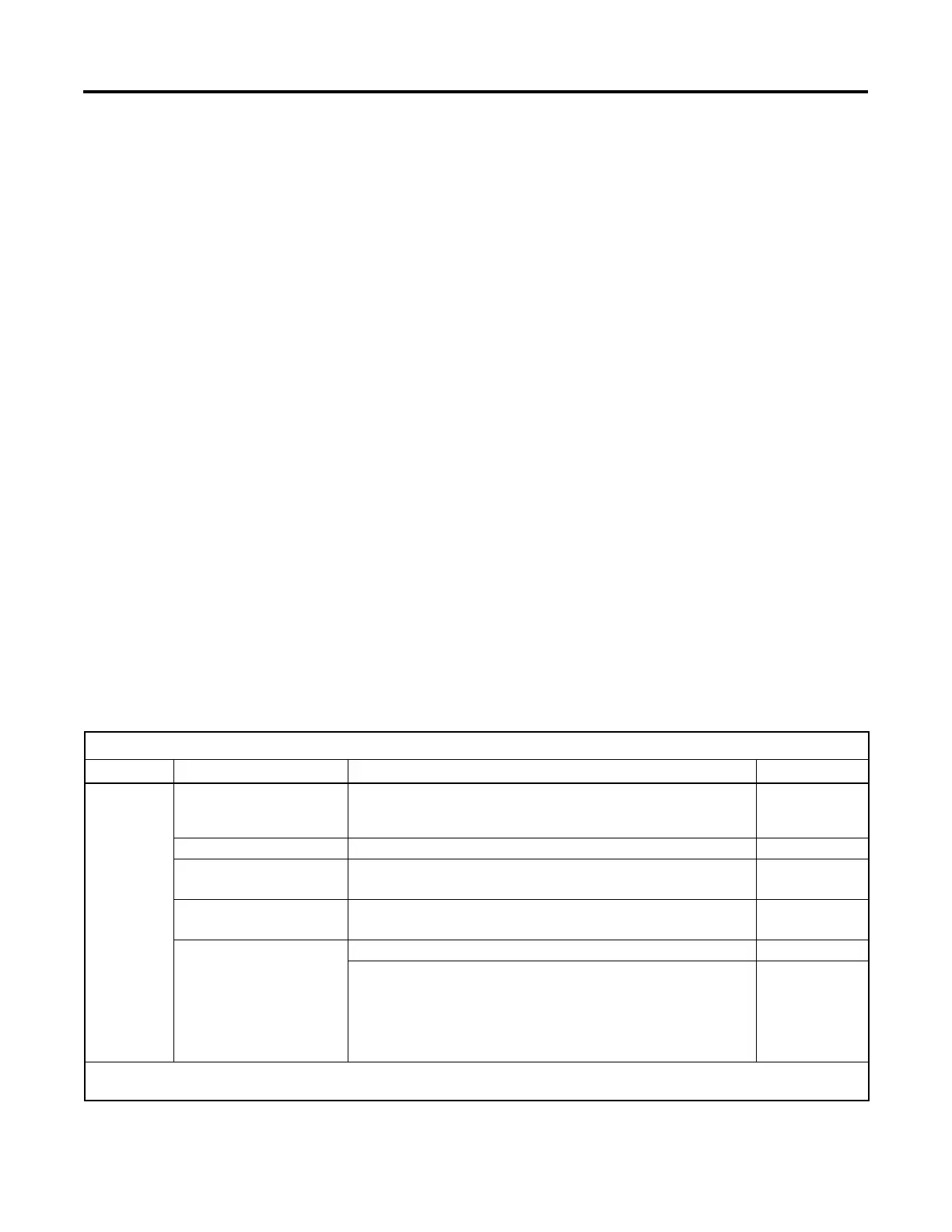

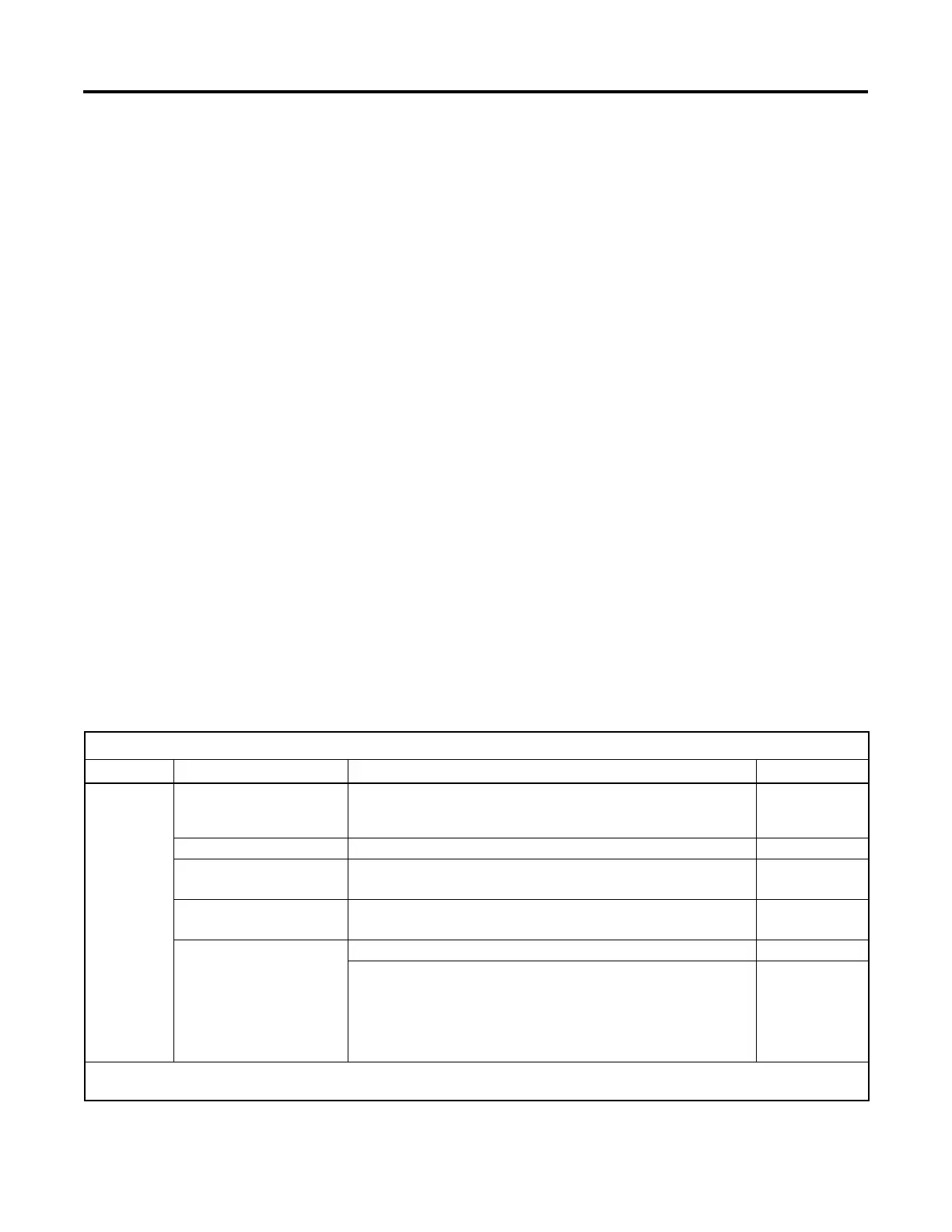

3.3 Troubleshooting Chart

Use the following table as a reference in troubleshooting

individual problems. Generator set faults are listed in

groups and include likely causes and remedies. The

simplest and most likely causes of the problem are listed

first; follow the recommendations in the order shown.

The reference column provides additional sources of

information in this and related manuals regarding the

problem and solution. See the List of Related Materials

for document part numbers.

Troubleshooting Chart

Problem Possible Cause Corrective Action Reference

Generator

set does not

crank

Weak or dead battery Recharge or replace battery.

If battery is weak or dead, check battery charger fuse, power

supply, and operation.

O/M

Battery connections Check for reversed or poor battery connections. —

Open circuit in engine/

controller connections

Check for loose connections.

Check the wire harness continuity.

W/D

Blown fuse F3, controller Replace fuse; if fuse blows again, check circuit and

components.

Section 5.12;

W/D

Blown fuse F2, relay

interface board (RIB)

Replace fuse. Section 5.12

If fuse blows again, disconnect the board leads one at a time to

identify the cause of the blown fuse:

Lead 70A at the fuel valve

Lead 71A at P30

Leads FP and FN at the rotor

Repair or replace the component causing the blown fuse.

W/D

Engine S/M: Engine Service Manual I/M: Generator Set Installation Manual O/M: Generator Set Operation Manual

W/D: Wiring Diagram Manual

Loading...

Loading...