2.12.2 Communication Setup Submenu

Modbus

®

Communications

The controller communicates using Modbus

®

as a slave connection with the Modbus

®

master initiating the communication. The

controller seeks the system and alternator parameters and diagnostic information then responds back to the Modbus

®

master.

In addition, the controller accepts information to alter controller parameters including generator set starting and stopping. See

Figure 12. Refer to the List of Related Materials for available Modbus

®

literature.

Note:

Only one Modbus

®

master can be connected to the controller. Examples include the remote serial annunciator, monitoring

software, and switchgear applications.

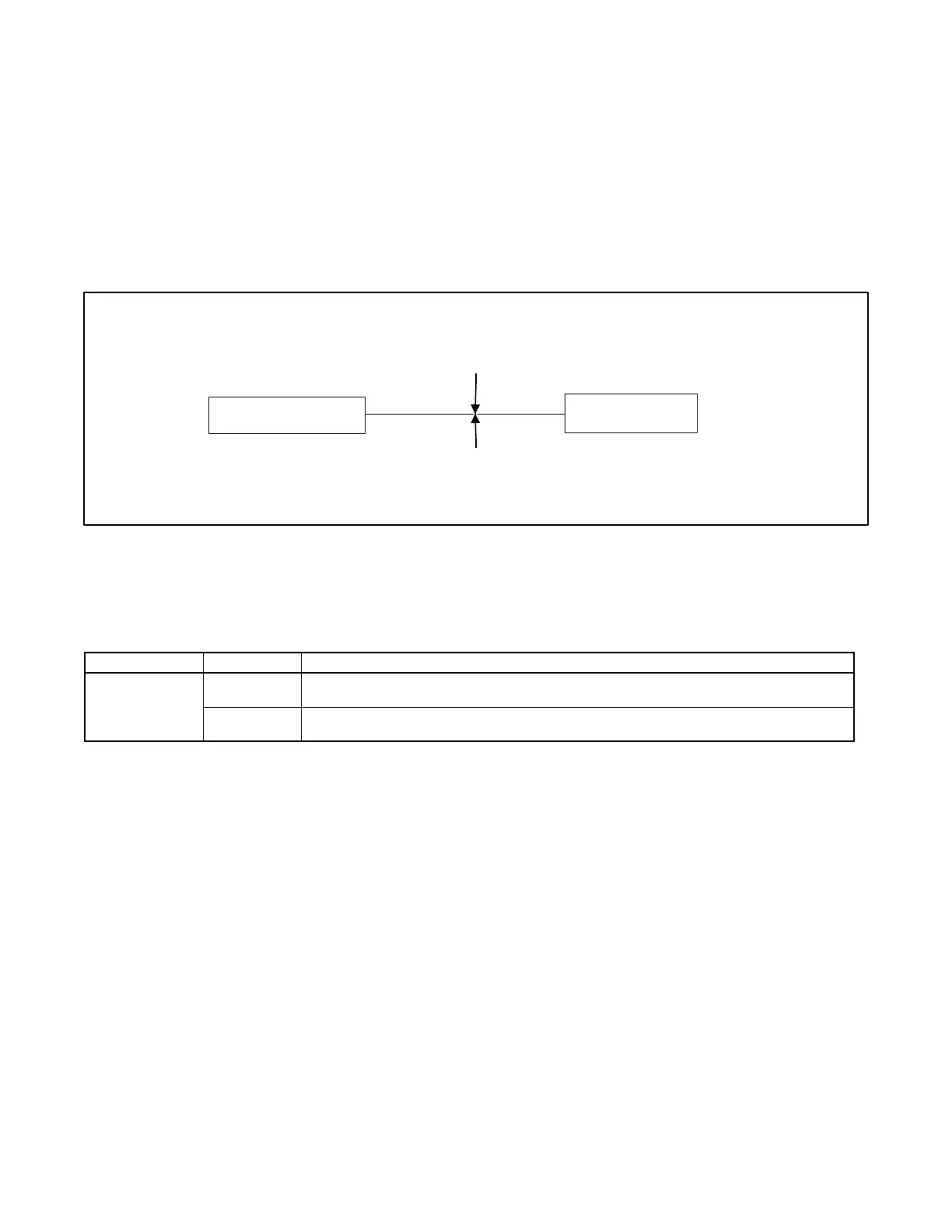

Figure 12 Modbus

®

Connections

A controller can communicate directly to a Modbus

®

master or participate in a network of devices. It can also be used to interface

a local master to a network of devices.

The Modbus

®

master polls slave devices for data. Controller devices are slaves. Examples of master devices are a personal

computer running monitoring software and the remote serial annunciator

9600, 19200, 38400, or 57600.

Must match the master PC and all devices in the system.

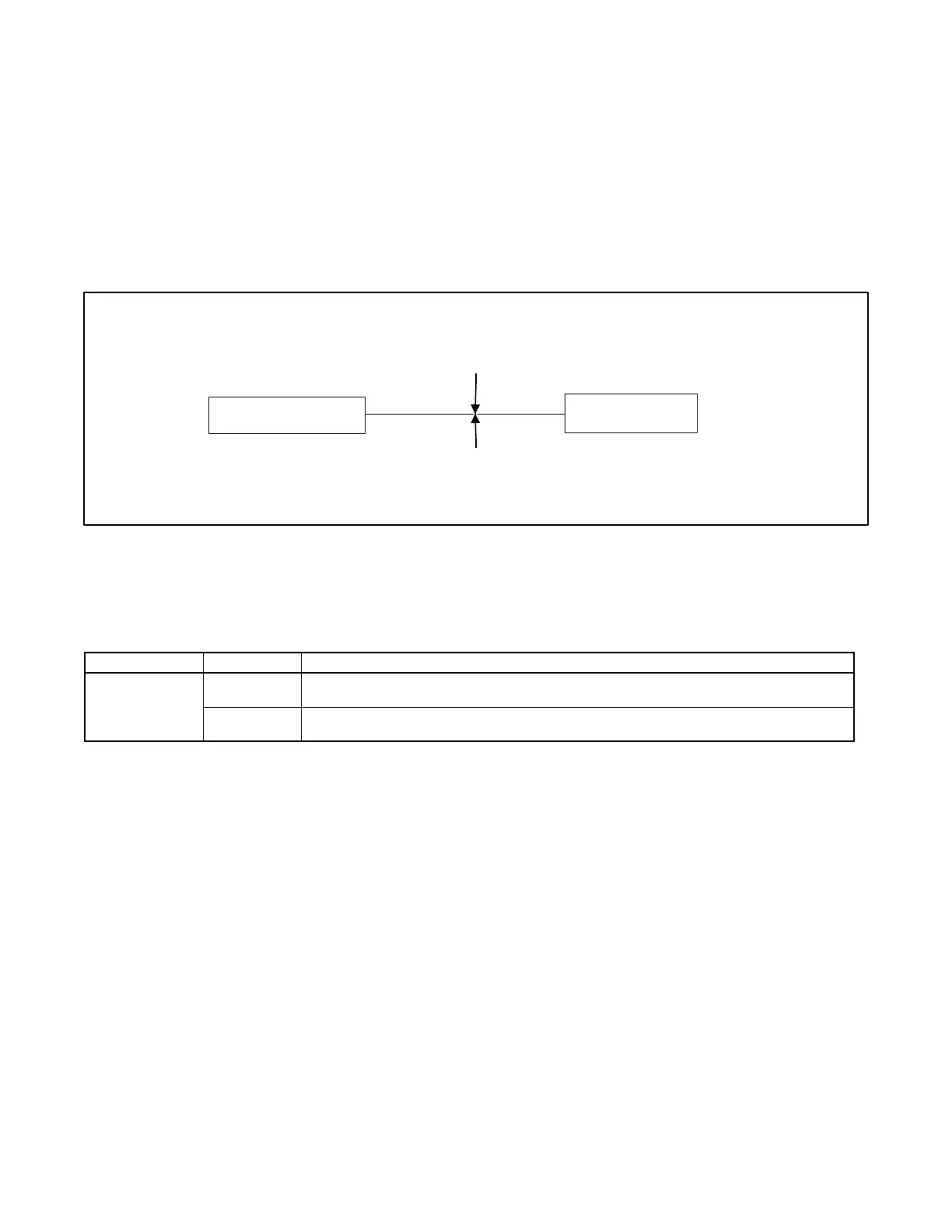

Figure 13 Decision-Modbus

®

3500 Communication Parameters

Select the baud rate. Choose the same baud rate for the Modbus

®

master, modems, and connected devices. See Figure 13.

Each generator set controller must have a unique Modbus

®

address and PGEN node number (1-4).

Note:

The PGEN node number is automatically determined. The number of nodes online should match the number of installed

generators.

Note:

The PGEN baud rate should not be adjusted except under direction from a factory service representative. Different baud rates

between controllers on the network will result in a loss of communication on the network.

Modbus

®

is a registered trademark of Schneider Electric.

Loading...

Loading...