23

EFI System

66 690 07 Rev. -- KohlerEngines.com

1. Check mounting and air gap of sensor. It must be

1.5 mm ± 0.25 mm (0.059 in. ± 0.010 in.).

2. Inspect wiring and connections for damage or

problems.

3. Make sure engine has resistor type spark plugs.

4. Disconnect main harness connector from ECU.

5. Connect an ohmmeter between #9 and #10 pin

terminals.

A resistance value of 750-1000 Ω at room

temperature (20°C, 68°F) should be obtained. If

resistance is correct, check mounting, air gap,

toothed ring gear (damage, runout, etc.), and

fl ywheel key.

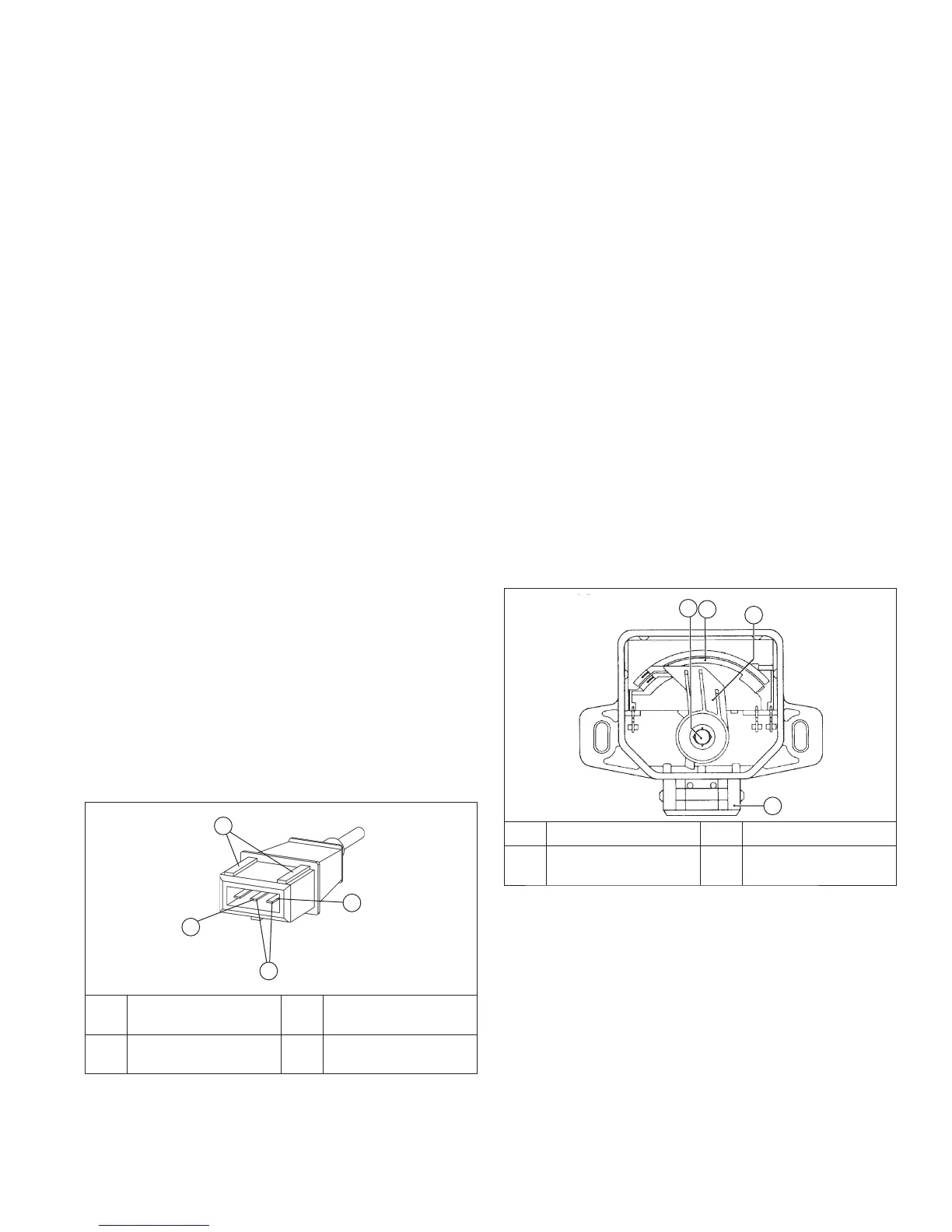

6. Disconnect speed sensor connector from wiring

harness. It is connector with one heavy black lead.

Viewing connector as shown (dual aligning rails on

top), test resistance between terminals indicated. A

reading of 750-1000 Ω should again be obtained.

7. If resistance is incorrect, remove screw securing

sensor to mounting bracket and replace sensor.

a. If resistance in step 5 was incorrect, but

resistance of sensor alone was correct, test main

harness circuits between sensor connector

terminals and corresponding pin terminals in main

connector. Correct any observed problem,

reconnect sensor, and perform step 5 again.

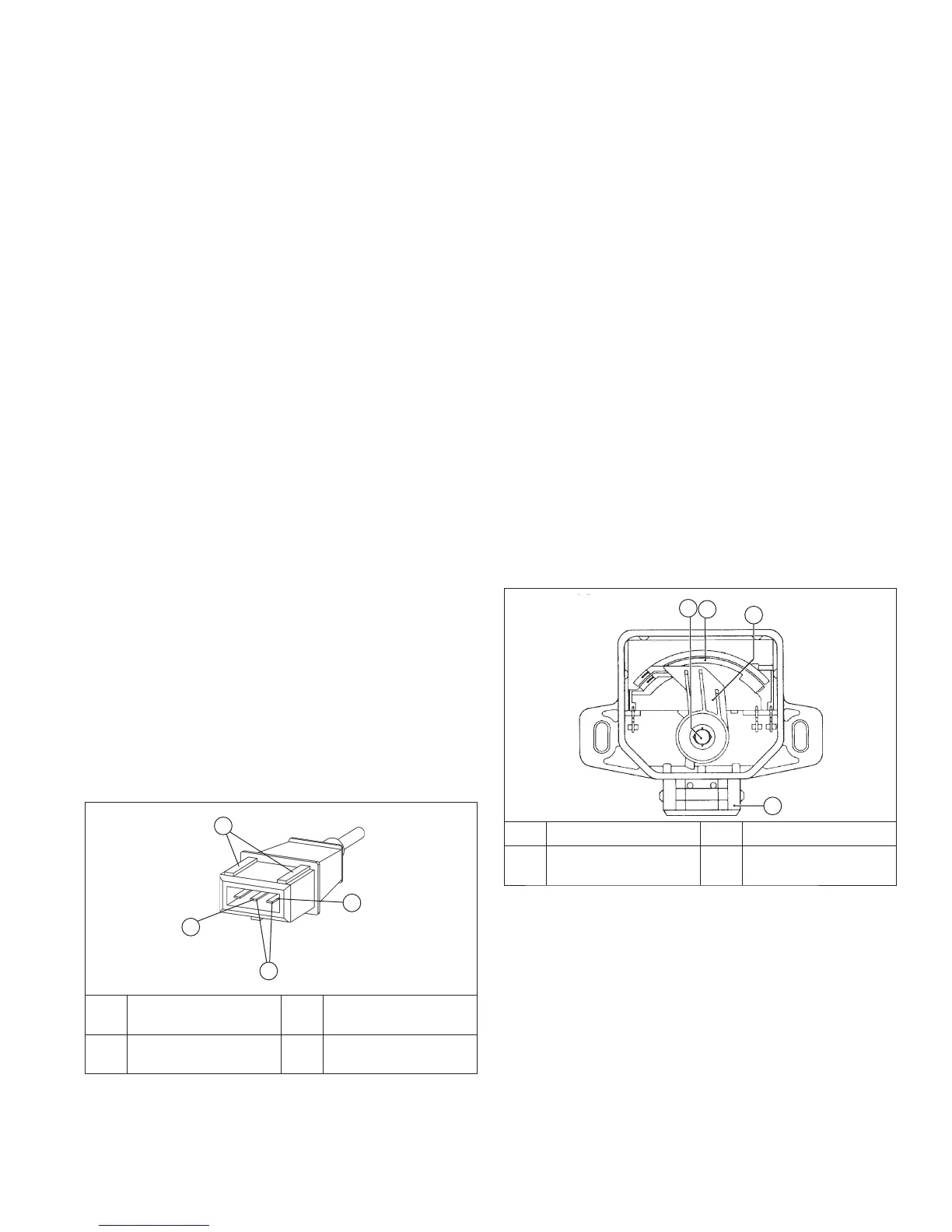

Throttle Position Sensor (TPS)

A

C

B

D

A Throttle Valve Shaft B Resistor Track

C

Wiper Arm with

Wiper

D

Electrical

Connection

TPS is a sealed, non-serviceable assembly. If diagnosis

indicates a bad sensor, complete replacement is

necessary. If a blink code indicates a problem with TPS,

it can be tested as follows:

1. Counting number of turns, back out idle speed

adjusting screw (counterclockwise) until throttle

plates can be closed completely.

2. Disconnect main harness connector from ECU, but

leave TPS mounted to throttle body/manifold.

3. Connect Red (positive) ohmmeter lead to #8 pin

terminal, and Black (negative) ohmmeter lead to #4

pin terminal. Hold throttle closed and check

resistance. It should be 800-1200 Ω.

a. Turn key switch to ON/RUN position. Fuel pump

will run for about three seconds and stop. Turn

switch off and back on to restart fuel pump.

Repeat this procedure until fuel pump has cycled

fi ve times, then start engine.

3. System can also be primed similar to relieving

pressure.

a. Connect pressure gauge as described above for

relieving fuel pressure. Depress and hold release

button and crank engine until air is purged and

fuel is visible in discharge tube. If fuel is not

visible after 10 seconds, stop cranking and allow

starter to cool for 60 seconds.

Priming Without a Test Valve in Fuel Rail

NOTE: Number of cranking intervals necessary will

depend on individual system design, and/or

when system has been disassembled.

1. Crank engine in 10-15 second intervals, allowing a

60 second cool-down period between cranking

intervals, until engine starts.

ELECTRICAL COMPONENTS

A 32 pin (MSE 1.1) plastic-cased ECU is used on these

engines.

Never attempt to disassemble ECU. It is sealed to

prevent damage to internal components. Warranty is

void if case is opened or tampered with in any way.

All operating and control functions within ECU are

preset. No internal servicing or readjustment may

be performed. If a problem is encountered, and you

determine ECU to be faulty, contact your source

of supply. Do not replace ECU without factory

authorization.

Relationship between ECU and throttle position sensor

(TPS) is very critical to proper system operation. If TPS

or ECU is changed, or mounting position of TPS is

altered, applicable TPS Initialization Procedure must be

performed to restore synchronization.

ENGINE SPEED SENSOR

Speed Sensor Circuit

A

D

C

B

A

Corresponds To #10

In Main Connector.

B Dual Aligning Rails

C

Corresponds To #9

In Main Connector.

D Test Terminals

Engine speed sensor is a sealed, non-serviceable

assembly. If Fault Code diagnosis indicates a problem

within this area, check and test as follows.

Loading...

Loading...