30

EFI System

KohlerEngines.com 66 690 07 Rev. --

5. Always use new O-rings and hose clamps when

installing a regulator. A new replacement regulator

will have new O-rings already installed. Lubricate

O-rings (external regulator) with light grease or oil.

6. Install new regulator by carefully pushing and

rotating it slightly into base or housing.

a. External Regulators with Square Base Housing

Only; Install a new O-ring between regulator and

mounting bracket. Set mounting bracket into

position.

b. Secure regulator in base with original retaining

ring or screws. Be careful not to dent or damage

body of regulator as operating performance can

be affected.

7. Reassemble and connect any parts removed in step

3.

8. Reconnect negative (–) battery cable.

9. Recheck regulated system pressure at fuel rail test

valve.

Fuel Rail

Fuel rail is mounted to throttle body/intake manifold. No

specifi c servicing is required unless operating conditions

indicate that it needs internal cleaning or replacement.

It can be detached by removing mounting screws and

injector retaining clips. Thoroughly clean area around

all joints and relieve any pressure before starting any

disassembly.

Throttle Body/Intake Manifold Assembly

Throttle body/intake manifold is serviced as an

assembly, with throttle shaft, TPS, throttle plates,

and idle speed adjusting screw installed. Throttle

shaft rotates on needle bearings (non-serviceable),

capped with rubber seals to prevent air leaks. A throttle

shaft repair kit is available to replace shaft if worn or

damaged. Appropriate TPS Initialization Procedure must

be performed after any throttle shaft service.

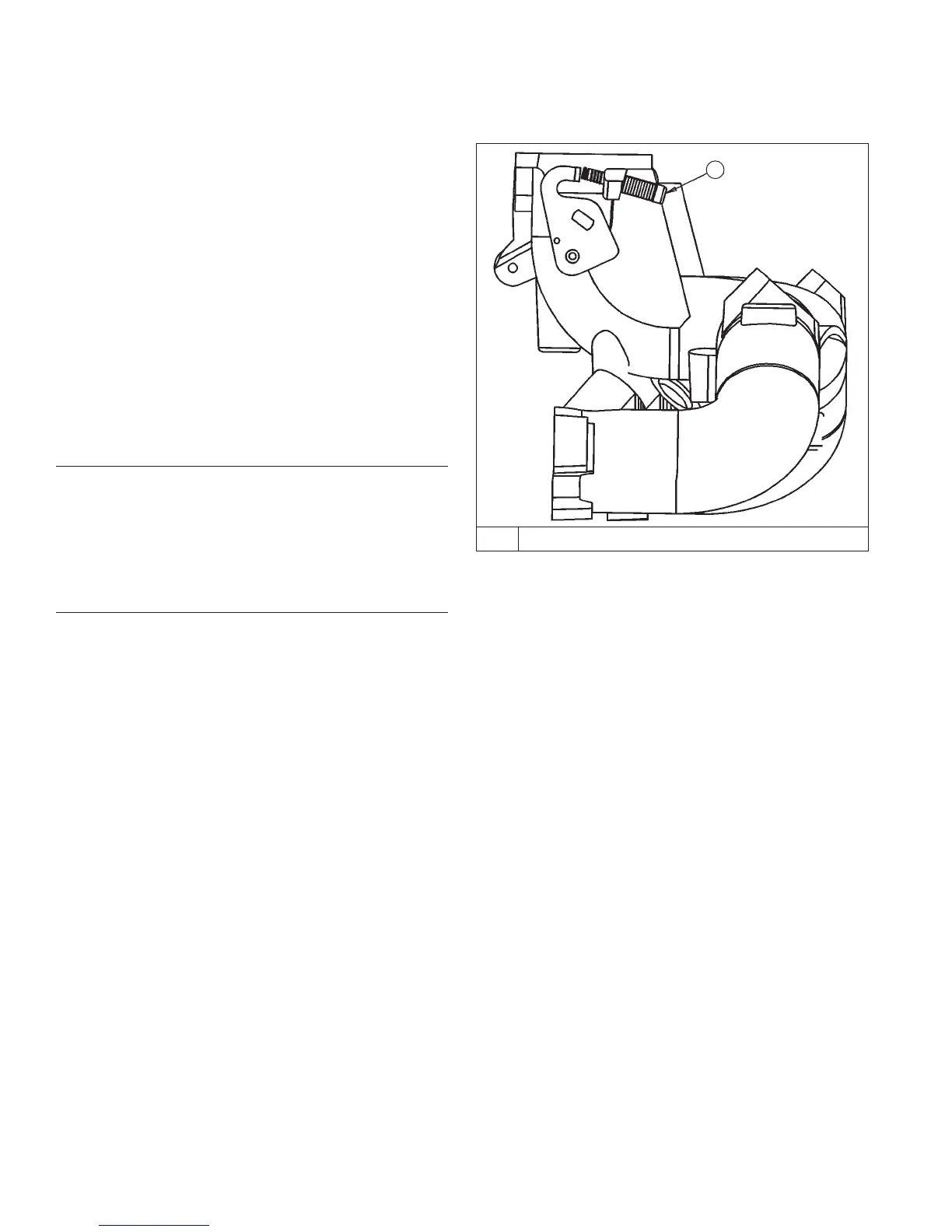

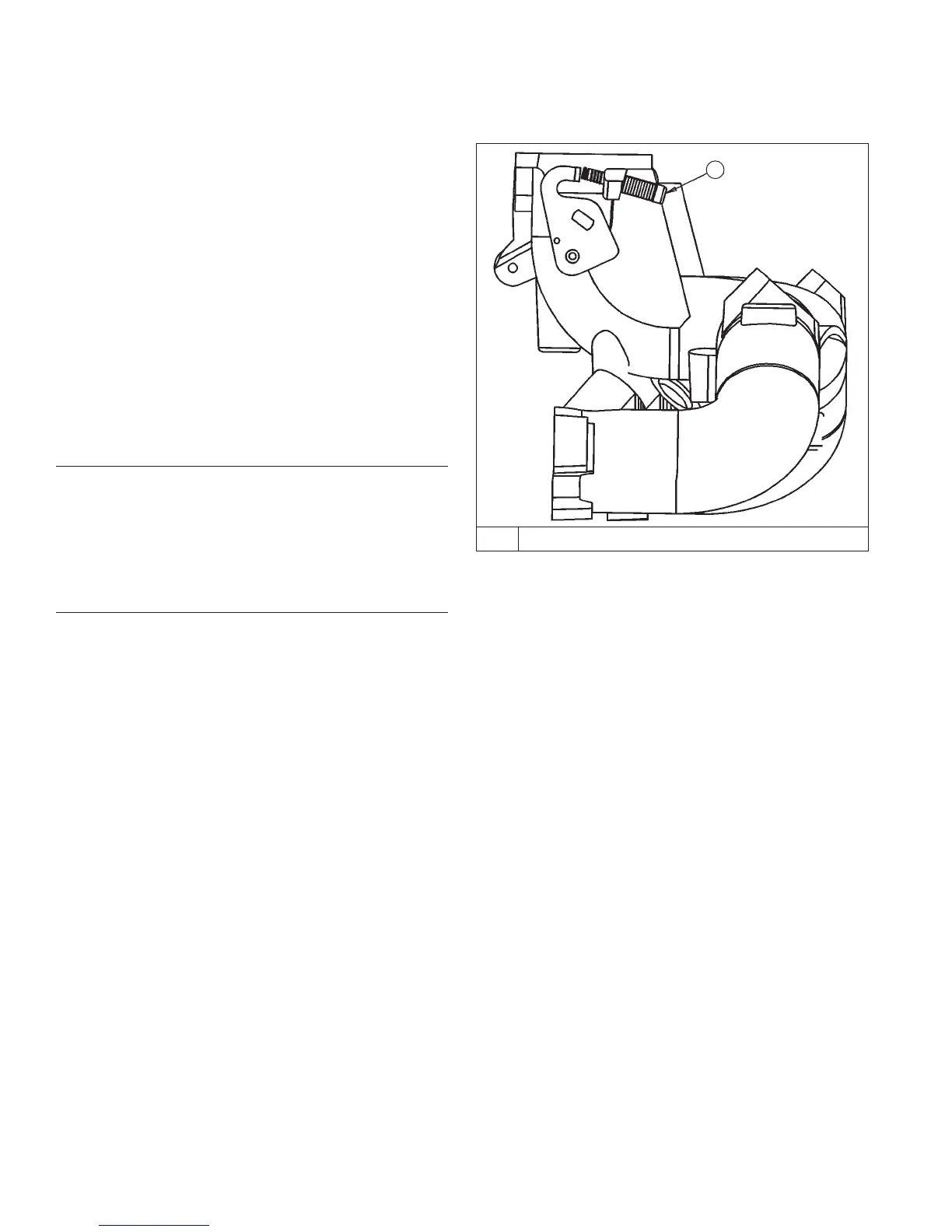

IDLE SPEED ADJUSTMENT (RPM)

Idle Speed Screw Details

A

A Idle Speed Screw

Adjustment Procedure

1. Make sure there are no fault codes present in ECU

memory.

2. Start engine and allow it to fully warm up and

establish closed looped operation (approximately

5-10 min.).

3. Place throttle control in IDLE/SLOW position and

check idle speed with a tachometer. Turn idle speed

screw in or out as required to obtain 1500 RPM, or

idle speed specifi ed by equipment manufacturer.

4. Idle speed adjustment can affect high idle speed

setting. Move throttle control to full throttle position

and check high idle speed. Adjust as necessary to

3750 RPM, or speed specifi ed by equipment

manufacturer.

INITIAL GOVERNOR ADJUSTMENT

Initial governor adjustment is especially critical on

EFI engines because of accuracy and sensitivity of

electronic control system. Incorrect adjustment can

result in overspeed, loss of power, lack of response, or

inadequate load compensation. If you encounter any

of these symptoms and suspect them to be related to

governor setting, following should be used to check and/

or adjust governor and throttle linkage.

If governor/throttle components are all intact, but you

think there may be a problem with adjustment, follow

Checking Initial Adjustment to check setting. If governor

lever was loosened or removed, go immediately to

Setting Initial Adjustment to perform initial adjustment.

Loading...

Loading...