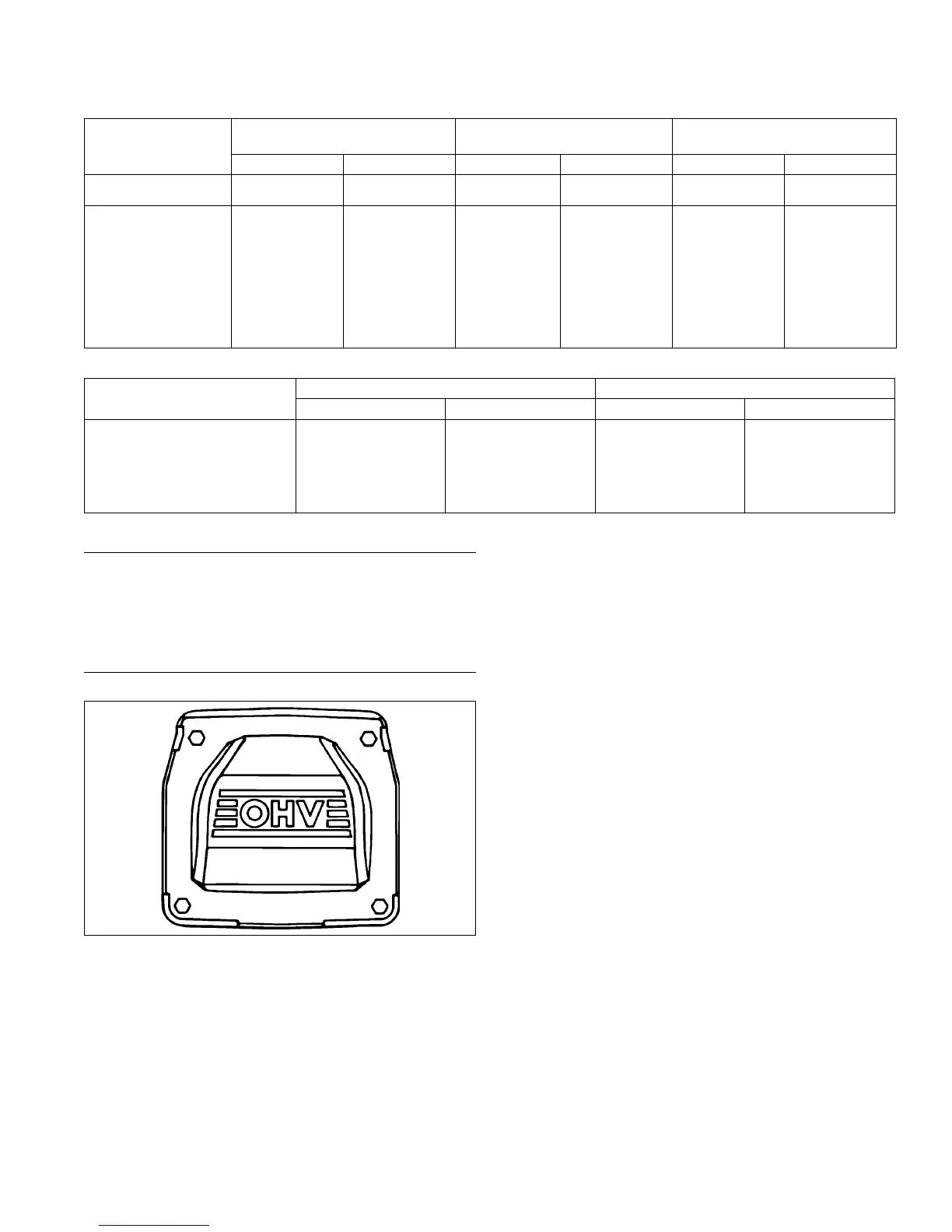

8 mm Governor Lever and Hole Position/RPM Chart for CH20-CH740 Engines

Governor Shaft

Conguration

Intended Maximum RPM

Non-Accelerator Pump

Carburetor

Accelerator Pump Carburetor

High Idle WOT Spring Color Hole No. Spring Color Hole No.

Needle Bearing

3744 3600 Orange 2 - -

3120 3000 Clear 1 - -

Standard

(Parent Material)

3888 3600 Red 4 Purple 3

3780 3500 Purple 3 Black 3

3672 3400 Black 3 Red 3

3564 3300 Red 3 Orange 2

3456 3200 Purple 2 Blue 2

3348 3100 Blue 2 Orange 1

3240 3000 Orange 1 Black 1

3132 2900 Clear 2 Red 1

3024 2800 Red 1 Clear 1

8 mm Governor Lever and Hole Position/RPM Chart for CH750 Engines

Governor Shaft

Conguration

Intended Maximum RPM With Governed Idle System

High Idle WOT Spring Color Hole No.

Standard

(Parent Material)

3888

3780

3672

3564

3456

3348

3600

3500

3400

3300

3200

3100

Blue

Purple

Orange

Green

Black

Red

3

2

1

1

1

1

Install Control Panel (if equipped)

1. Install panel to blower housing.

2. Connect throttle control cable or shaft.

3. Connect choke control cable to control bracket.

4. Connect Oil Sentry

™

indicator light wires.

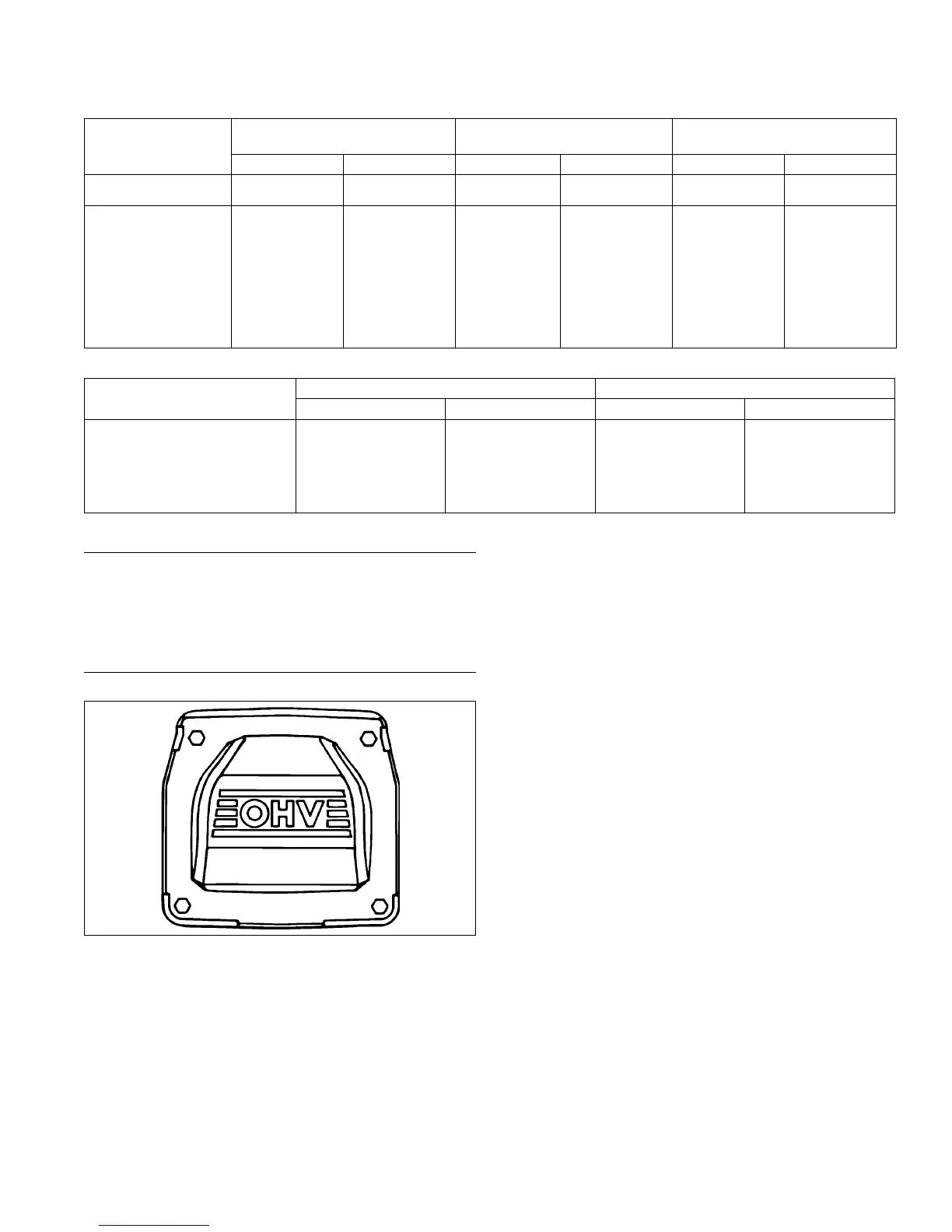

Install Valve Covers

Torque Sequence

1

2

3

4

NOTE: Do not scrape old RTV sealant (if used) off

sealing surface of cylinder head as this could

cause damage and result in leaks. Use of gasket

remover solvent (paint remover) is

recommended.

NOTE: Second fastener may secure fuel pump bracket

on earlier models.

Three valve cover designs have been used. First type

used a gasket and RTV sealant between cover and

sealing surface of cylinder head. Second type had a

black O-ring installed in a groove on underside of cover

and may have metal spacers in bolt holes. Latest design

uses a yellow or brown O-ring, with bolt hole spacers

molded in place. Tightening torque differs between

gasket and O-ring style covers. Kits are available for

converting to latest O-ring type covers. Differences are

pointed out in following installation steps.

1. If using gasket or sealant type cover, prepare sealing

surfaces of cylinder head and cover, refer to Tools

and Aids for approved sealants. Always use fresh

sealant. Using outdated sealant could result in

leakage. With O-ring type covers, make sure sealing

surfaces are clean.

2. Make sure there are no nicks or burrs on sealing

surfaces.

3. For covers requiring RTV sealant, apply a 1.5 mm

(1/16 in.) bead to sealing surface of both cylinder

heads, install a new cover gasket on each, then

apply a second bead of sealant on top surface of

gaskets. For O-ring type covers, install a new O-ring

in groove of each cover. Do not use gaskets or RTV

sealant.

4. Locate cover with oil ll neck on same side as

removed and install lifting strap in original position.

With O-ring type covers, position cover on cylinder

head. If loose spacers were used, insert a spacer in

each screw hole. On both types, install four screws

in each cover and nger tighten.

5. Torque valve cover fasteners to proper specication

using sequence shown.

Reassembly

8724 690 06 Rev. J KohlerEngines.com

Loading...

Loading...