24

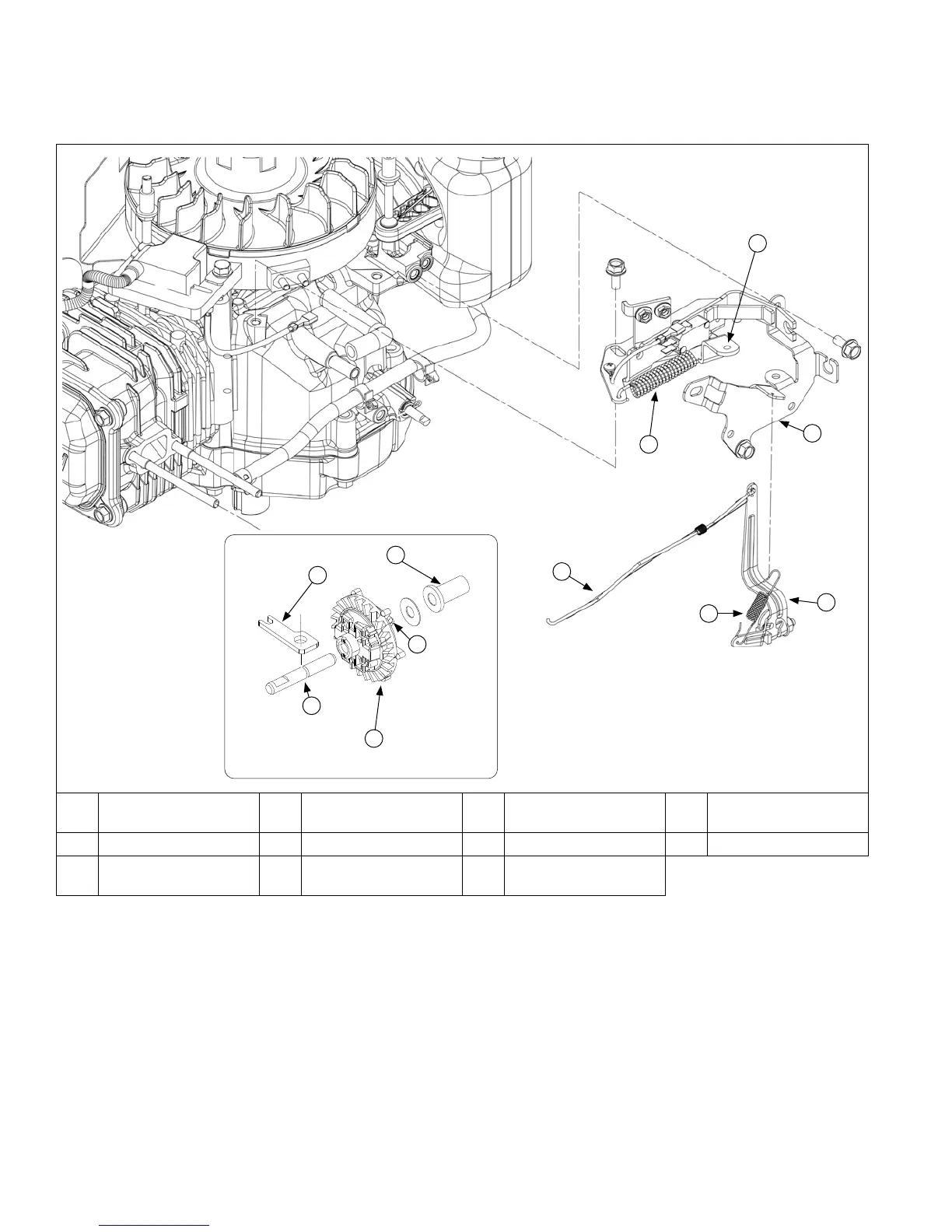

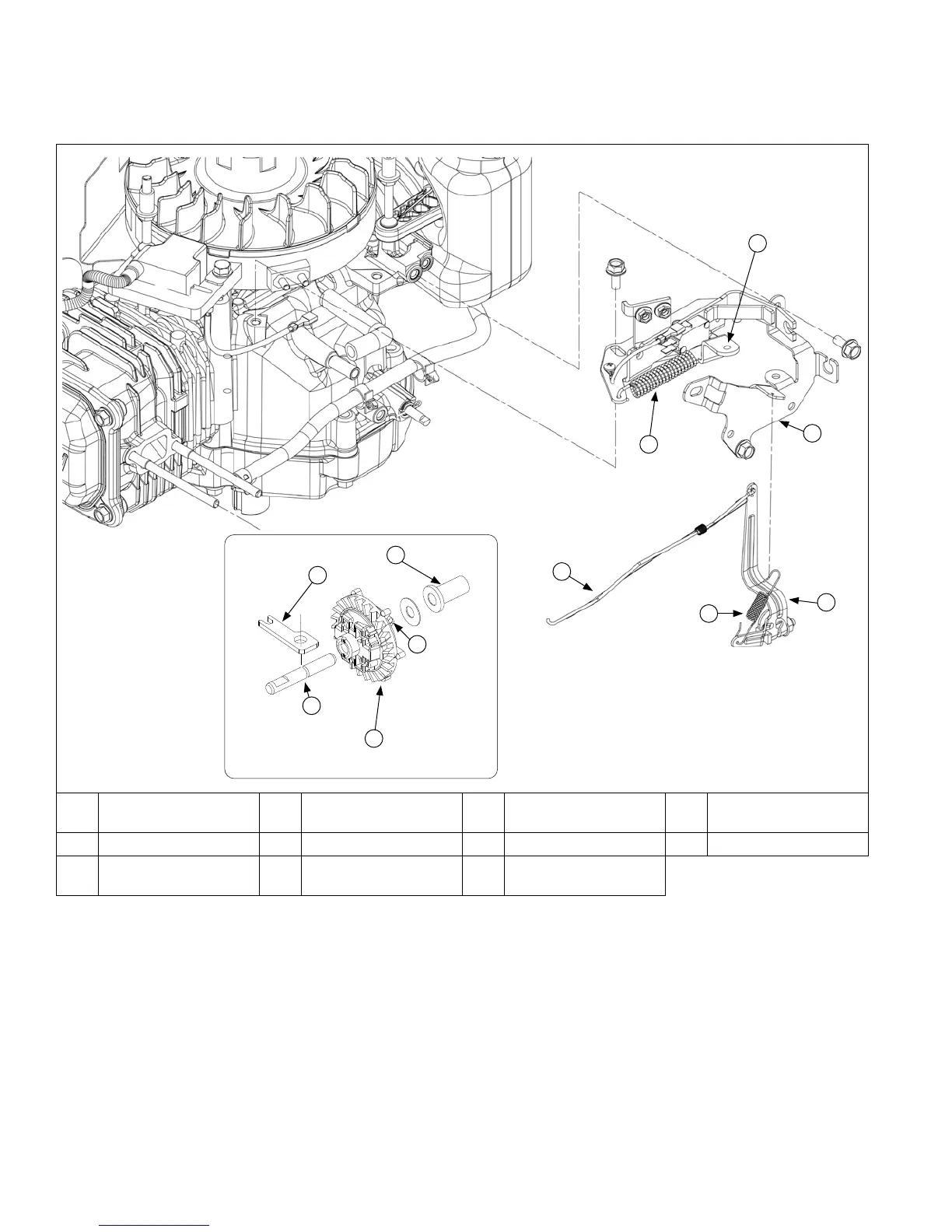

Governor System

KohlerEngines.com 14 690 01 Rev. G

Governed speed setting is determined by position of

throttle control. It can be variable or constant, depending

on engine application.

Governor is designed to hold engine speed constant

under changing load conditions. Most engines are

equipped with a centrifugal yweight mechanical

governor. Governor gear/yweight mechanism of

mechanical governor is mounted inside crankcase and is

driven off gear on camshaft.

This governor design works as follows:

● Centrifugal force acting on rotating governor gear

assembly causes yweights to move outward as

speed increases. Governor spring tension moves

them inward as speed decreases.

GOVERNOR

Governor Components

E

C

D

I

J

F

A

B

G

K

H

A Control Spring B

Intermediate Control

Lever

C Control Bracket D Governor Lever

E Compression Spring F Linkage G Regulating Pin H Flyweight(s)

I Governor Gear J Governor Gear Shaft K

Governor Shaft

Retainer

● As yweights move outward, they cause regulating pin

to move outward.

● Regulating pin contacts tab on cross shaft causing

shaft to rotate.

● One end of cross shaft protrudes through crankcase.

Rotating action of cross shaft is transmitted to throttle

lever of carburetor through external throttle linkage.

● When engine is at rest, and throttle is in fast position,

tension of governor spring holds throttle plate open.

When engine is operating, governor gear assembly is

rotating. Force applied by regulating pin against cross

shaft tends to close throttle plate. Governor spring

tension and force applied by regulating pin balance

each other during operation, to maintain engine

speed.

Loading...

Loading...