Fuel System

2332 690 03 Rev. E KohlerEngines.com

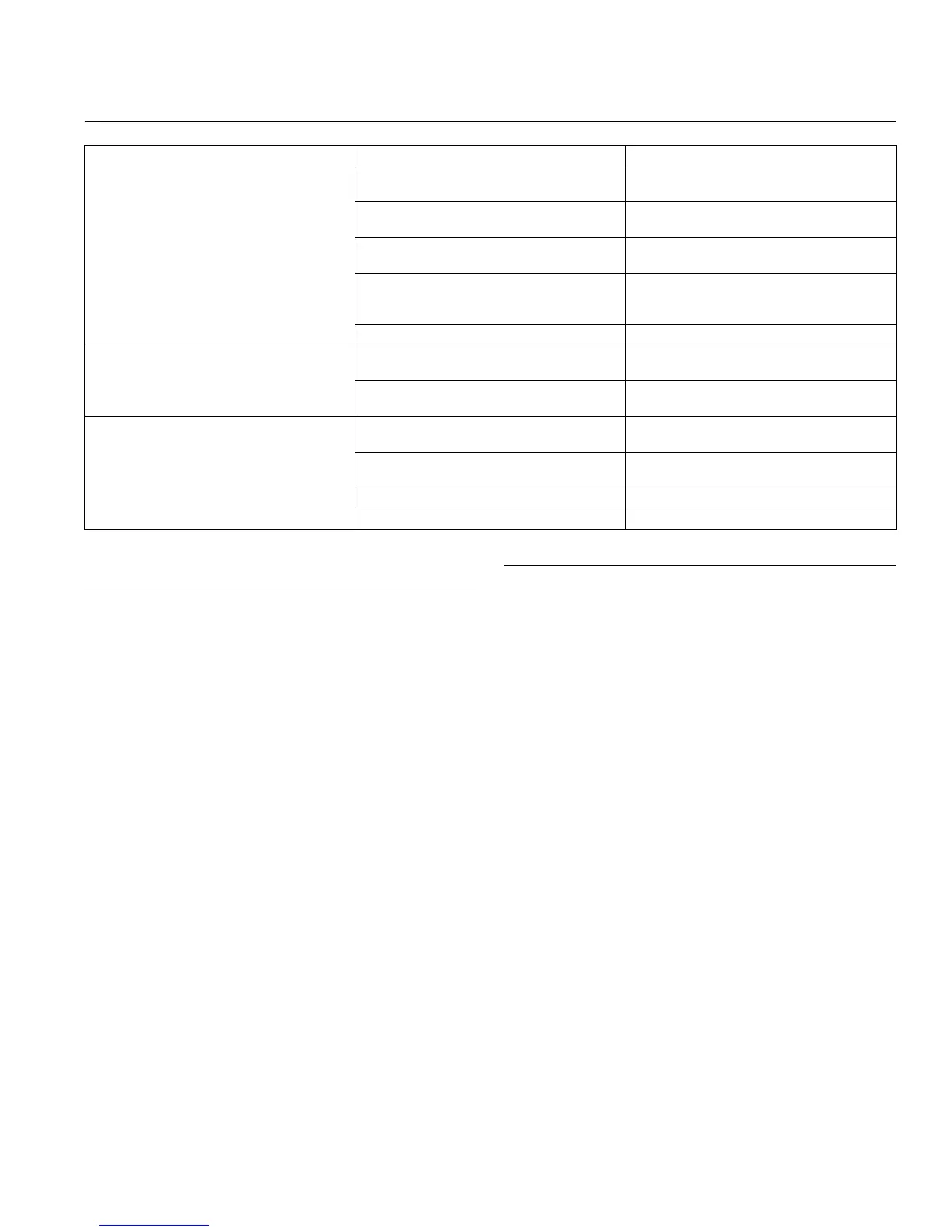

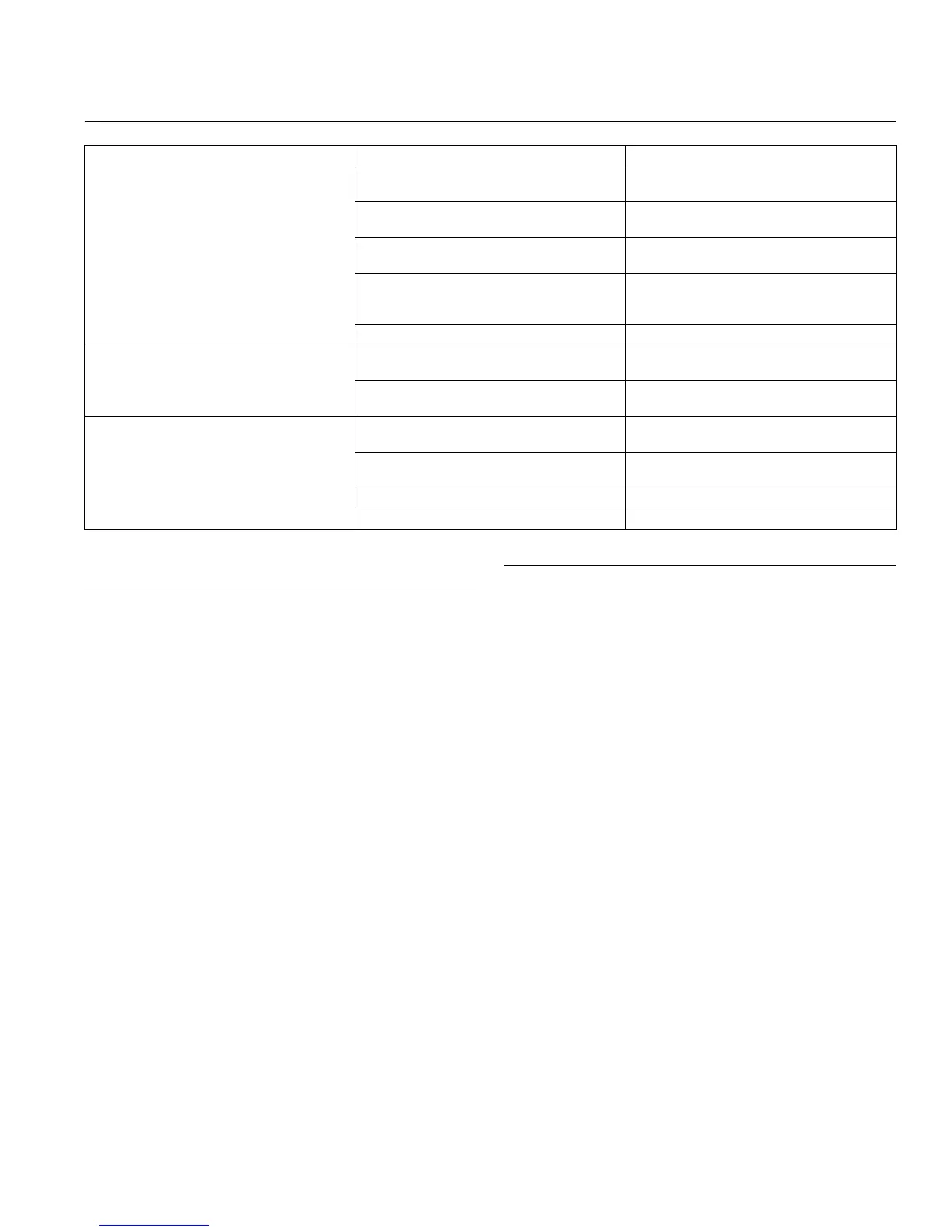

Troubleshooting-Carburetor Related Causes

Condition Possible Cause Conclusion

Engine runs rich (indicated by black,

sooty exhaust smoke, misring, loss

of speed and power, governor

hunting, or excessive throttle

opening).

Clogged air cleaner. Clean or replace air cleaner.

Choke partially closed during

operation.

Check choke lever/linkage to ensure

choke is operating properly.

Float level is set too high. Adjust oat (Keihin only, Walbro not

adjustable).

Dirt under fuel inlet needle. Remove needle; clean needle and

seat and blow with compressed air.

Bowl vent or air bleeds plugged. Clean vent, ports, and air bleeds.

Blow out all passages with

compressed air.

Leaky, cracked, or damaged oat. Submerge oat to check for leaks.

Engine runs lean (indicated by

misring, loss of speed and power,

governor hunting, or excessive

throttle opening).

Float level is set too low. Adjust oat (Keihin only, Walbro not

adjustable).

Idle holes plugged; dirt in fuel delivery

channels.

Clean main fuel jet and all passages;

blow out with compressed air.

Fuel leaks from carburetor. Float level set too high. Adjust oat (Keihin only, Walbro not

adjustable).

Dirt under fuel inlet needle. Remove needle; clean needle and

seat and blow with compressed air.

Bowl vents plugged. Blow out with compressed air.

Carburetor bowl gasket leaks. Replace gasket.

FUEL SYSTEM

Fuel Shut-off Solenoid

Most carburetors are equipped with a fuel shut-off

solenoid. Solenoid is attached to fuel bowl. Solenoid has

a spring-loaded pin that retracts when 12 volts is applied

to lead, allowing fuel ow to main jet. When current is

removed, pin extends blocking fuel ow.

Below is a simple test, performed with engine off, that

can determine if solenoid is functioning properly:

1. Shut off fuel and remove solenoid from carburetor.

When solenoid is loosened and removed, gas will

leak out of carburetor. Have a container ready to

catch fuel.

2. Wipe tip of solenoid with a shop towel or blow with

compressed air to remove any remaining fuel. Take

solenoid to a location with good ventilation and no

fuel vapors present. You will also need a 12 volt

power source that can be switched on and off.

3. Be sure power source is switched OFF. Connect

positive power source lead to red lead of solenoid.

Connect negative power source lead to solenoid

body.

4. Turn power source ON and observe pin in center of

solenoid. Pin should retract with power ON and

return to its original position with power OFF. Test

several times to verify operation.

Carburetor Circuits

Float

Fuel level in bowl is maintained by oat and fuel inlet

needle. Buoyant force of oat stops fuel ow when

engine is at rest. When fuel is being consumed, oat will

drop and fuel pressure will push inlet needle away from

seat, allowing more fuel to enter bowl. When demand

ceases, buoyant force of oat will again overcome fuel

pressure, rising to predetermined setting and stop ow.

Slow and Mid-Range

At low speeds engine operates only on slow circuit. As

a metered amount of air is drawn through slow air bleed

jets, fuel is drawn through main jet and further metered

through slow jet. Air and fuel are mixed in body of slow

jet and exit to idle progression (transfer port) chamber.

From idle progression chamber, air fuel mixture is

metered through idle port passage. At low idle air/fuel

mixture is controlled by setting of idle fuel adjusting

screws. This mixture is then mixed with main body of

air and delivered to engine. As throttle plate opening

increases, greater amounts of air/fuel mixture are drawn

in through xed and metered idle progression holes.

As throttle plate opens further, vacuum signal becomes

great enough at venturi so main circuit begins to work.

Main (high-speed)

At high speeds/loads engine operates on main circuit.

As a metered amount of air is drawn through air jet,

fuel is drawn through main jet. Air and fuel are mixed

in main nozzles then enters main body of airow where

further mixing of fuel and air occurs. This mixture is then

delivered to combustion chamber. Carburetor has a xed

main circuit; no adjustment is possible.

Loading...

Loading...